Dynamic quality metering equipment

A measurement equipment and quality technology, applied in weighing, measuring devices, weighing equipment with special properties/forms, etc., can solve problems such as insufficient precision, inability to meet production needs, and difficulty in achieving ultra-high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

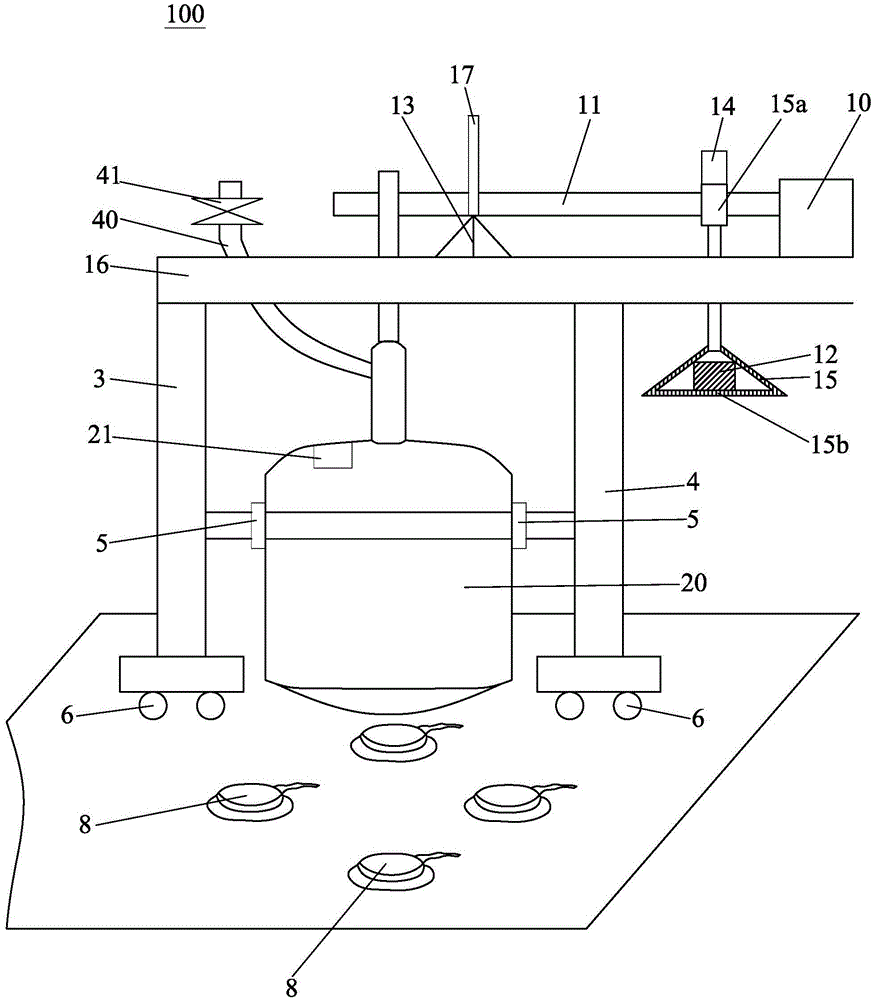

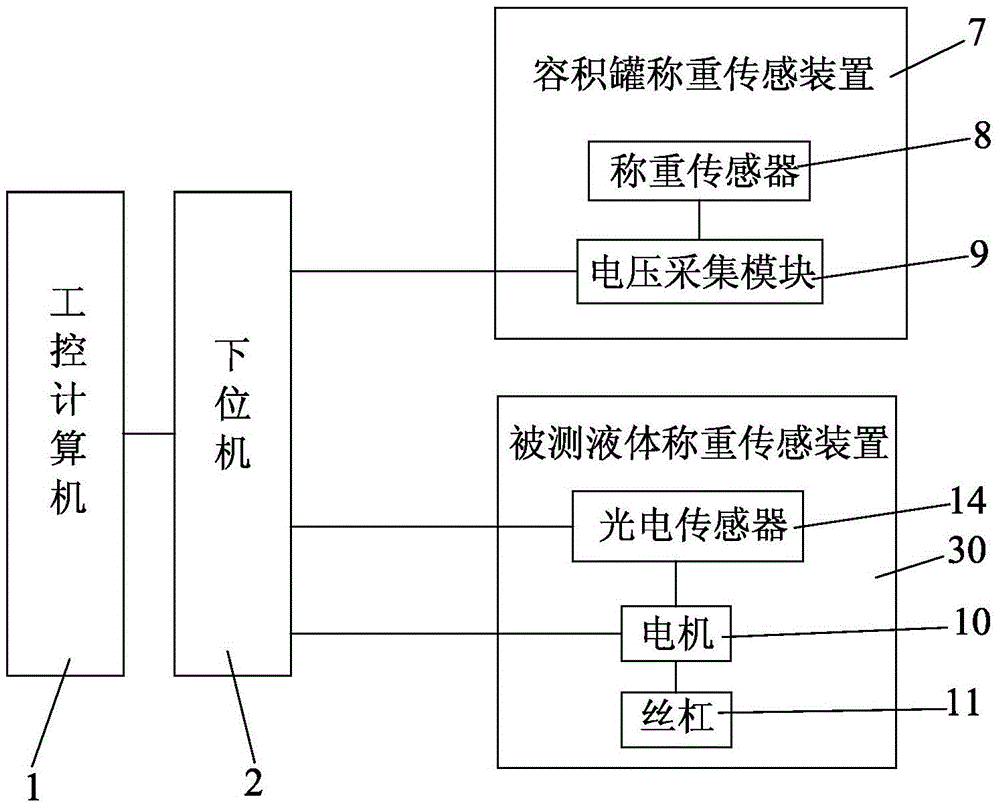

[0024] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 , 2 As shown, the present invention provides a dynamic mass measuring device 100 for accurately weighing the quality of the liquid in the volume tank 20, including:

[0025] The industrial computer 1 and the lower computer 2, the industrial computer 1 and the lower computer 2 communicate through a serial port, and the industrial computer 1 is pre-installed with a supporting software system, and the peripherals are configured with a display and an input device;

[0026] A volume tank 20 for containing the liquid to be measured, the two sides of the volume tank 20 are respectively provided with a left bracket 3 and a right bracket 4, and the left bracket 3 and the right bracket 4 are lifting structures and have the same structure as the volume tank 20. The engaged engaging part 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com