Automatic measuring device and measuring method for sludge specific resistance

A sludge specific resistance and measuring device technology, which is applied in the direction of measuring the increase and deceleration rate of fluid, using liquid/vacuum degree to measure liquid tightness, and weighing by removing certain components, can solve the problem that cannot meet the requirements of sludge Engineering practice and theoretical teaching needs, problems affecting accurate reading of filtrate volume, inaccurate filter cake measurement, etc., to avoid air leakage and liquid leakage, easy to read and record test data, novel and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

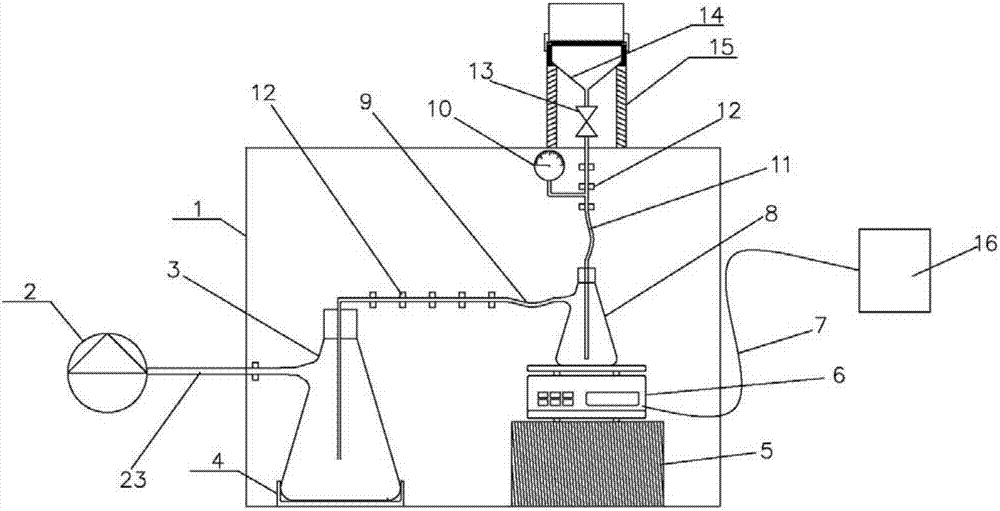

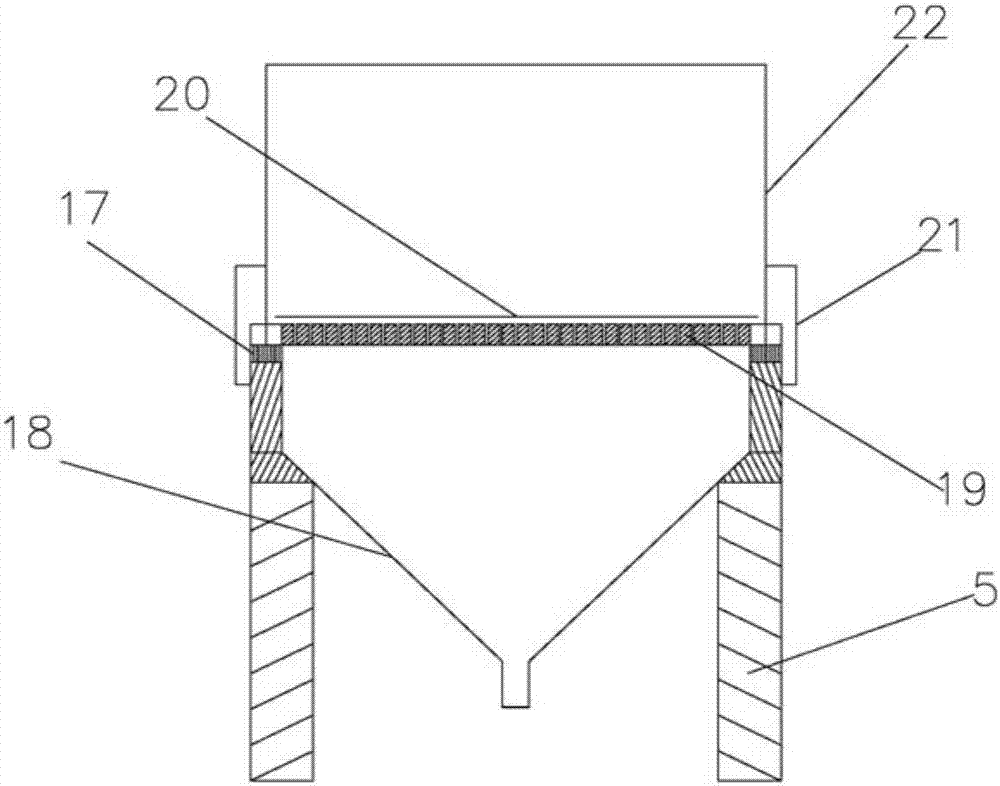

[0060] Depend on Figure 1 to Figure 3 Provided, a kind of automatic sludge specific resistance measuring device of the present invention is characterized in that, comprises airtight test case 1 and is arranged on the electronic balance 6 in the airtight test case 1, intermediate buffer bottle 3, is placed on the electronic balance 6 and has suction filter The bottle 8, the suction filter bottle 8 and the intermediate buffer bottle 3 are all airtight hollow structures, the airtight test box 1 is provided with a suction filter funnel 14, and the suction filter funnel 14 is provided with a horizontal porous support plate 19, and on the porous support plate 19 Evenly distributed with up and down suction filter holes, the porous support plate 19 is covered with filter paper 20, the lower mouth of the suction filter funnel 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com