Underwater self-contained sound intensity instrument and sound intensity measurement method

A sound intensity meter, self-contained technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as literature reports of underwater self-contained sound intensity meters, and save post-processing time. , Improve overall performance and indicators, enrich the effect of selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

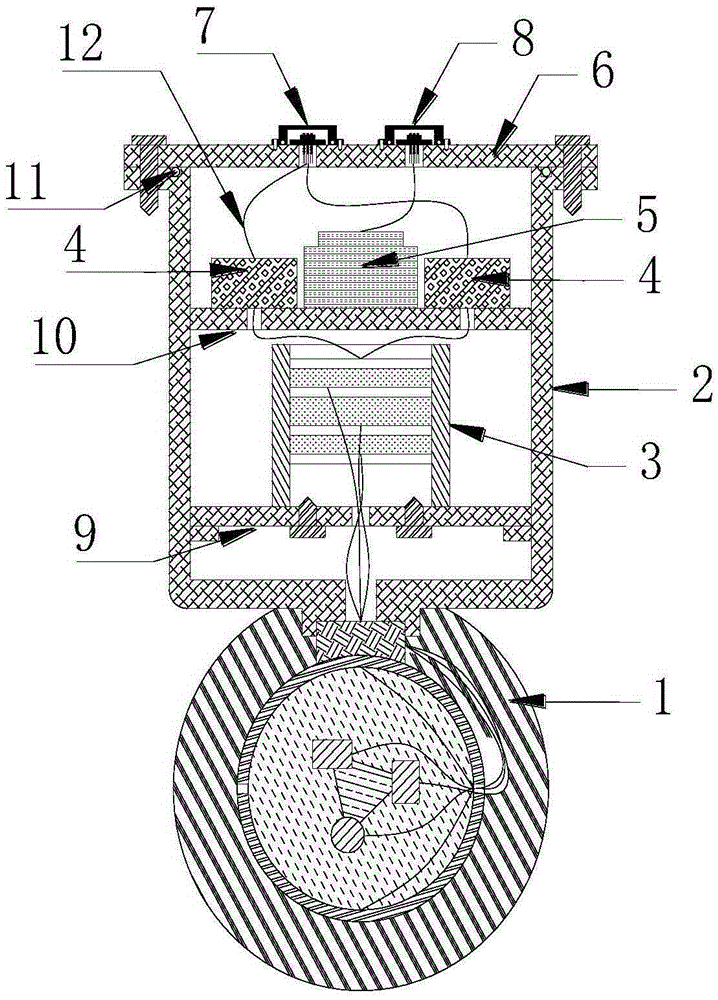

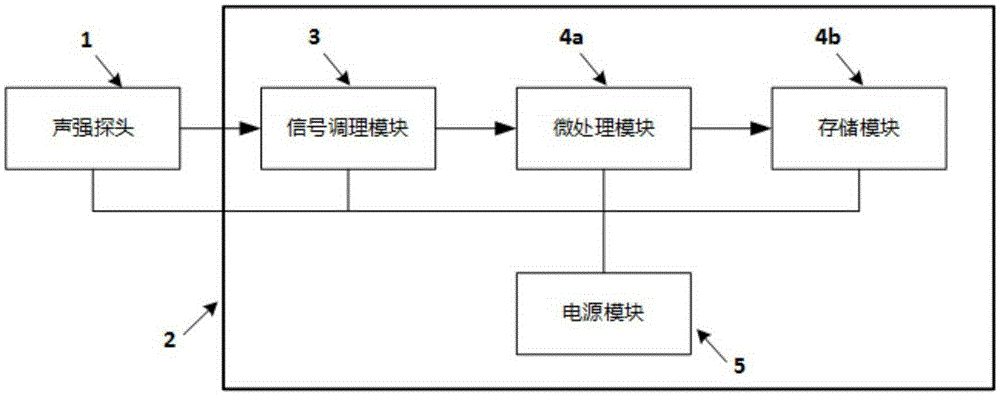

[0036] The purpose of the present invention is to overcome the deficiencies in the prior art, to provide a sound intensity probe using a vector hydrophone, and to integrate a signal conditioning module, a microprocessing module, a data storage module and a power supply module into a storage device. As the underwater wet end in the cabin, the three-dimensional underwater self-contained sound intensity meter can store the instantaneous sound intensity, average sound intensity and complex sound intensity data in the instrument without using cables.

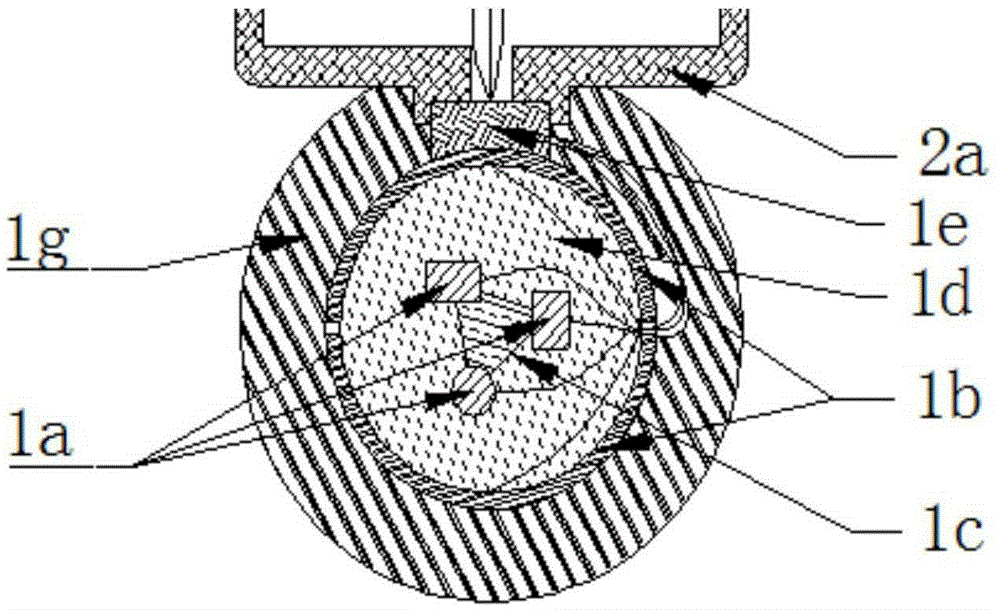

[0037] The sound intensity probe is composed of three independent vibration sensors and two hemispherical piezoelectric ceramics. The vibration sensor is placed in the center of the hemispherical piezoelectric ceramics. The two are poured together with low-density composite materials, and finally coated with polyuret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com