A non-destructive flaw detection device for welded pipe joints

A non-destructive flaw detection and pipe joint technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as being unfavorable to workshop production, consuming manpower and material resources of enterprises, etc., to achieve the effect of easy large-scale use, low manufacturing cost, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

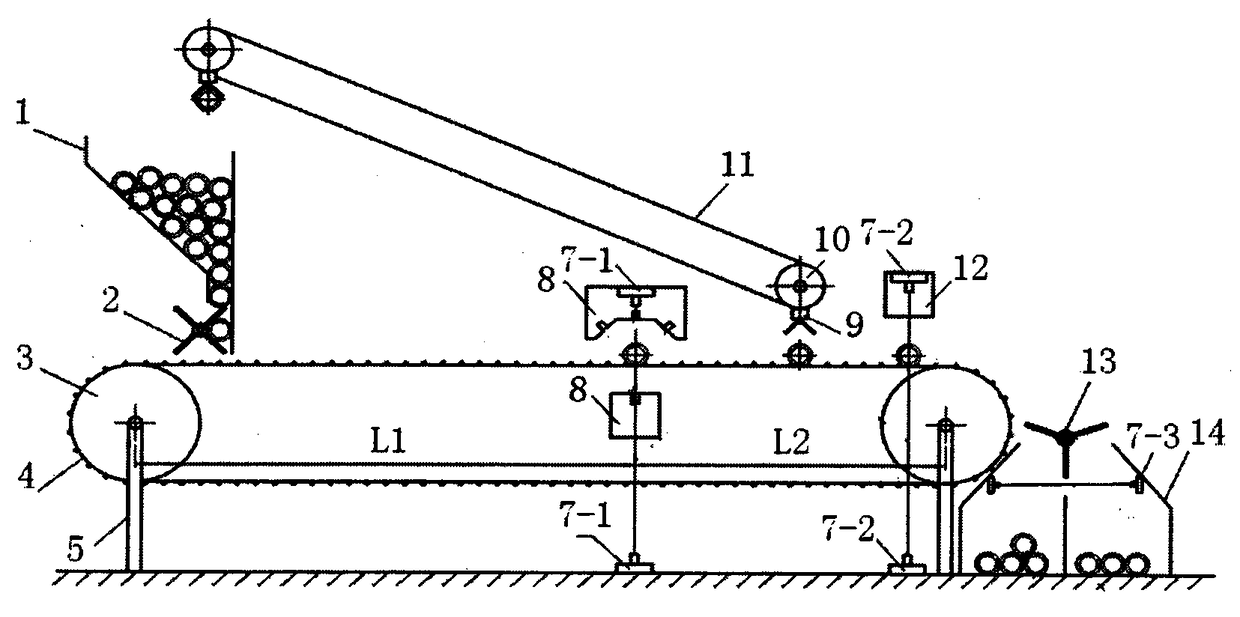

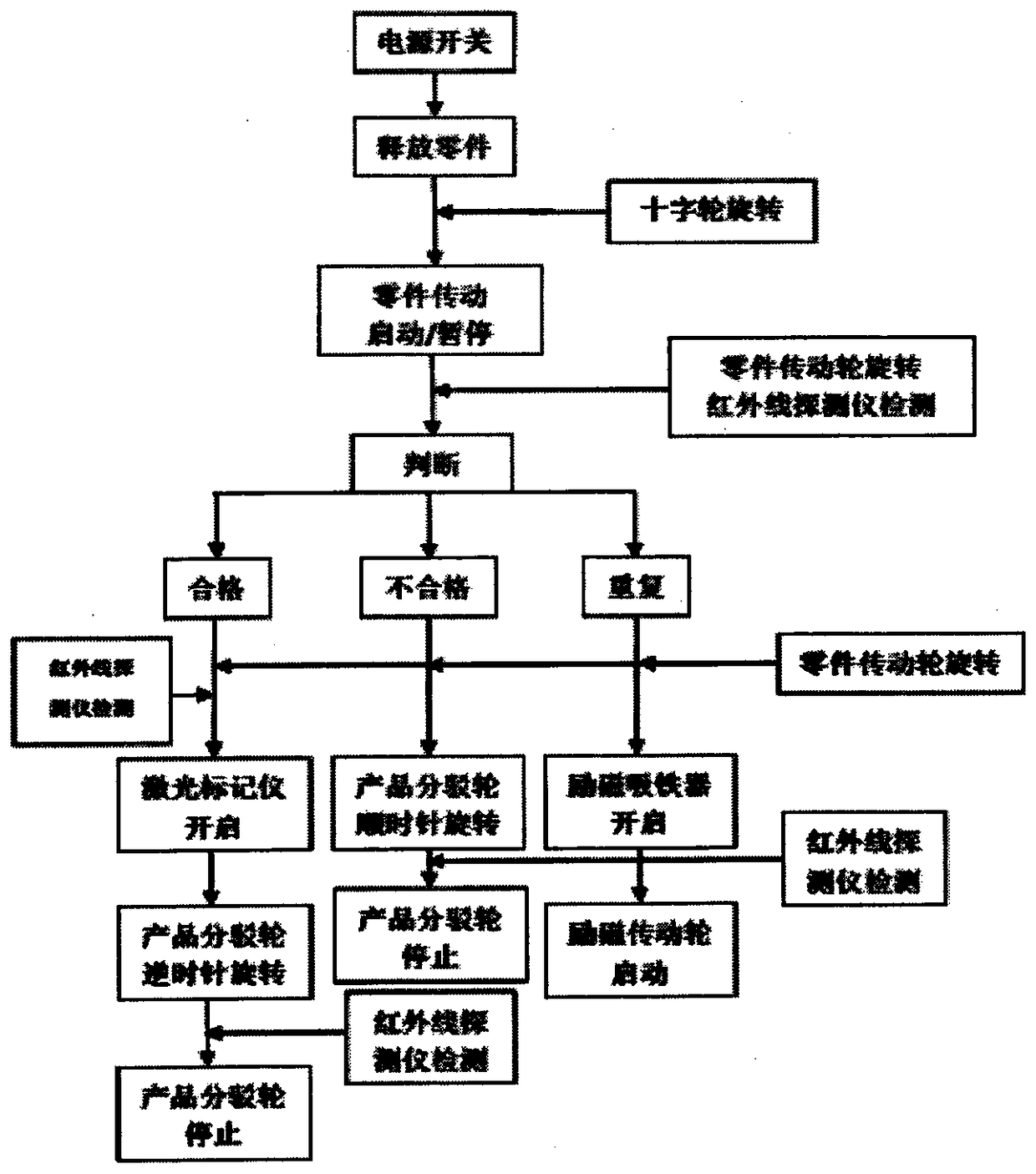

[0027] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

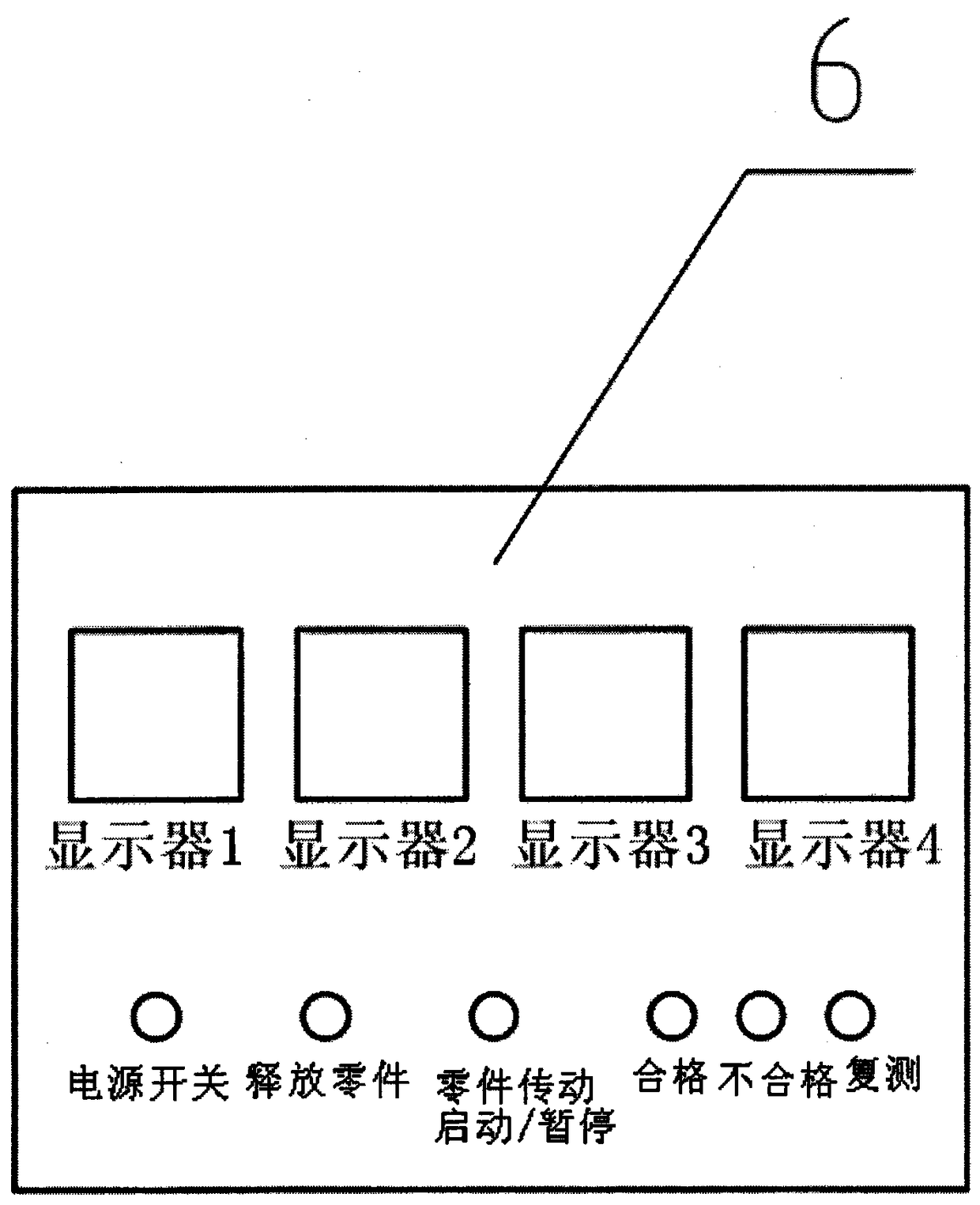

[0028] combine figure 1 As shown, a non-destructive flaw detection device for welded pipe joints provided by the present invention includes a storage box 1, a cross wheel 2, a transmission wheel 3, a transmission belt 4, a bracket 5, a control box 6, an infrared detector-7-1, an infrared Detector Two 7-2, Infrared Detector Three 7-3, Multi-angle TV Flaw Detector 8, Excitation Iron Absorber 9, Excitation Drive Wheel 10, Excitation Drive Belt 11, Laser Marker 12, Product Barge Wheel 13, Product Stacking Box 14 and electric control box.

[0029] Mechanisms such as the cross wheel 2, the transmission wheel 3, the excitation drive wheel 10, and the product sorting wheel 13 are all externally connected to a gear box and an electric motor. Cross wheel 2, transmission wheel 3, control box 6, infrared detector 1 7-1, infrared detector 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com