Tire ultrasonic NDT (Non-Destructive Testing) device and method

A non-destructive testing and ultrasonic technology, applied in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc., can solve problems such as low detection efficiency and inconvenient detection, and improve efficiency , Simplify the operation process, and detect the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

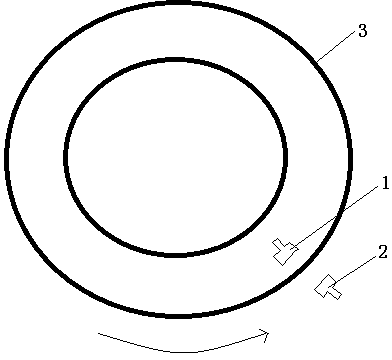

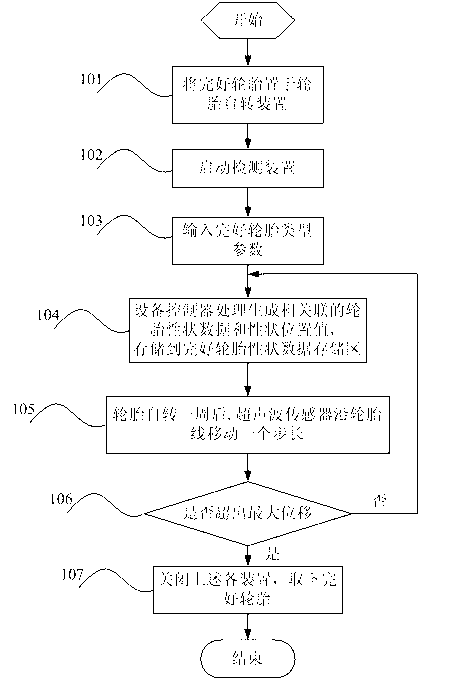

[0050] This specific embodiment includes a pair of ultrasonic transmitter 1 / ultrasonic sensor 2, and the pair of ultrasonic transmitter / ultrasonic sensor is installed on the inner and outer sides of the tire 3 respectively, and transmits / receives low frequency of 120K HZ to 400K HZ through air coupling Ultrasonic, non-contact non-destructive testing of tires; such as figure 1 shown.

[0051] A tire rotation device drives the tire to rotate around the axis at a certain speed, figure 1 The direction of the arrow in is the direction of tire rotation.

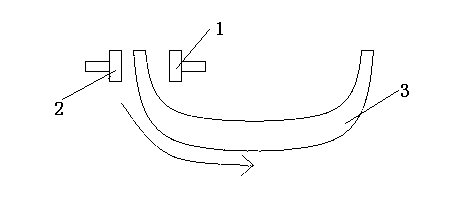

[0052] An ultrasonic transmitter / ultrasonic sensor pair moving device drives the ultrasonic transmitter / ultrasonic sensor pair to move along the tire line on the tire section, such as figure 2 as shown, figure 2 The direction of the arrow in is the moving direction of the ultrasonic transmitter / ultrasonic sensor pair.

[0053] An equipment controller, respectively connected to the ultrasonic sensor and the ultrasonic transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com