Light guide plate assembly, backlight and display device

A display device and light guide plate technology, which is applied in optical components, light guides, optics, etc., can solve the problems of thick backlight modules, general appearance quality, and large-size light guide plates that cannot be cut and screen-printed to achieve thinning Design, improve the appearance quality, and solve the effect that the screen printing cannot be cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order for those skilled in the art to better understand the technical solution of the present invention, the light guide plate assembly, backlight source and display device provided by the present invention will be described in detail below with reference to the accompanying drawings.

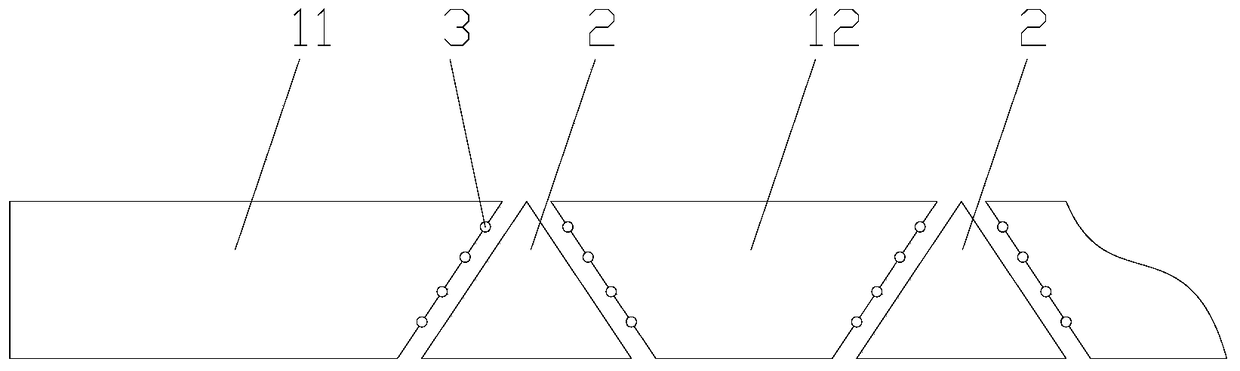

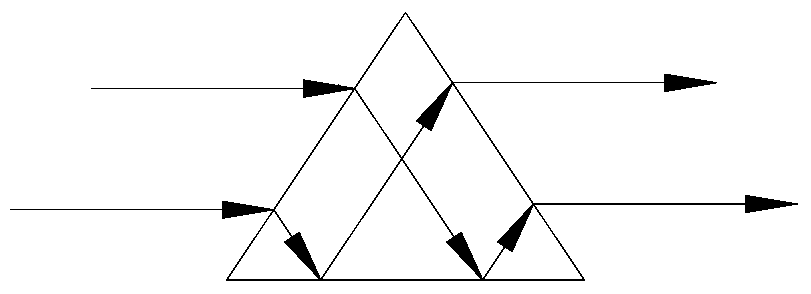

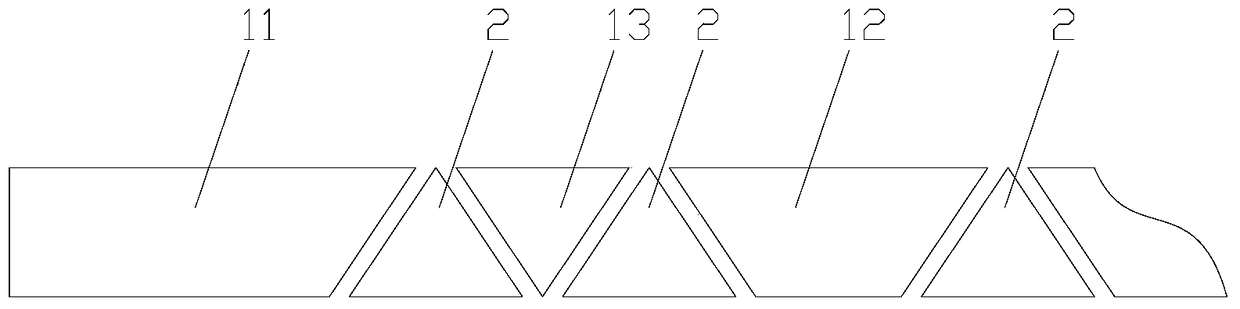

[0026] figure 1 A partial schematic diagram of the light guide plate assembly provided by the first embodiment of the present invention. see figure 1 , the light guide plate assembly includes N light guide plate splicing blocks and N-1 total reflection lenses, and N is an integer greater than 1, wherein, the N light guide plate splicing blocks are sequentially arranged at intervals along the light propagation direction. Among the N light guide plate splicing blocks, the projections of two light guide plate splicing blocks 11 respectively located at the near light end (the end close to the light source) and the far light end (the end far away from the light source) on a plane parallel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap