Preset value adjusting method for ingredients, mixing plant ingredient control method and systems

An adjustment method and a technology for adjusting the system, which are applied in batching batching instruments, batching weighing instruments, mixing operation control and other directions to achieve accurate batching, improve production efficiency and quality, and improve batching accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

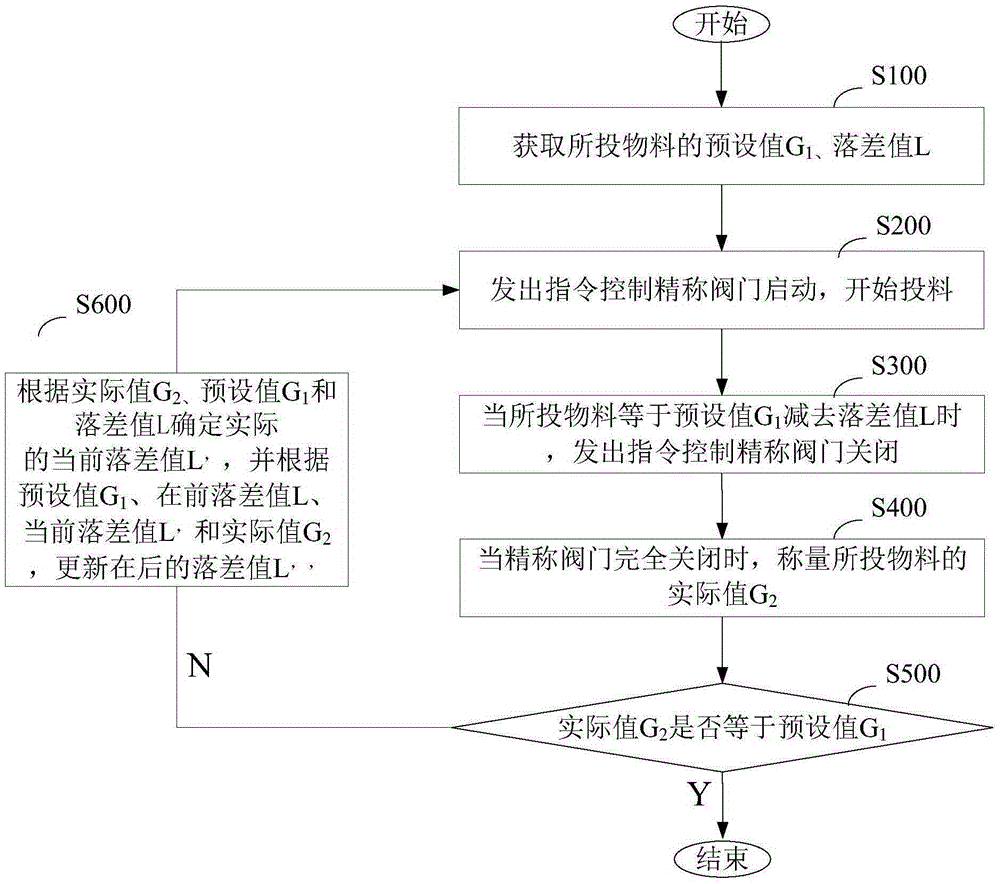

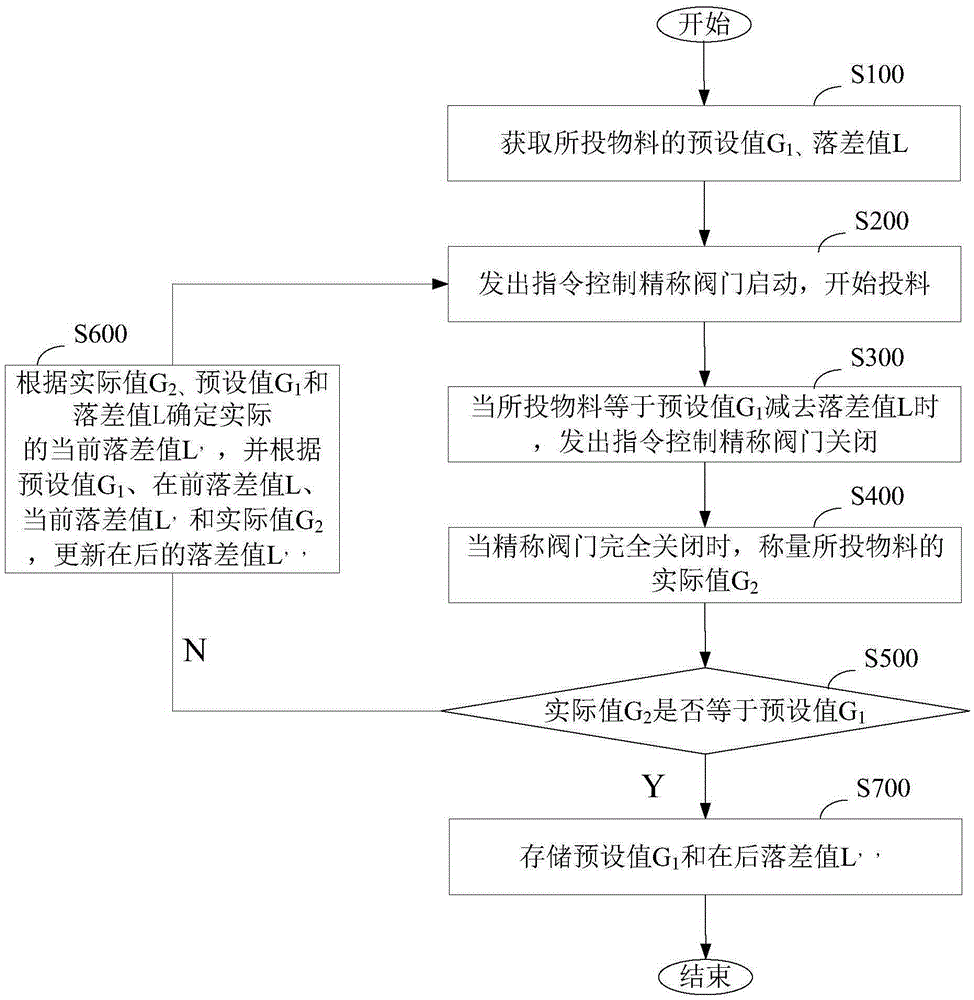

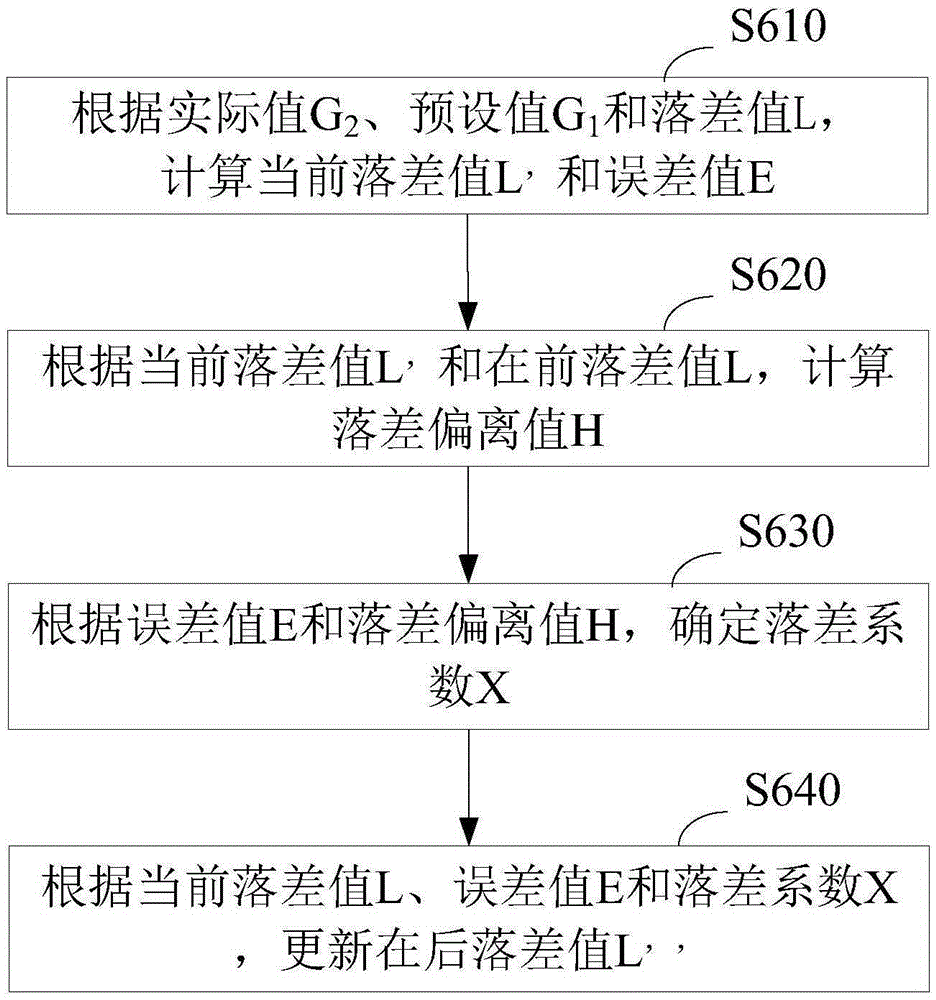

[0048] In order to describe the technical idea of the present invention in detail, the batching process of a concrete mixing plant is taken as an example below to describe in detail. According to the problem analysis of the background technology, the present invention provides a method for adjusting the preset value of ingredients, in order to adjust the materials thrown each time to the preset value, such as figure 1 As shown, the specific steps include:

[0049] S100: Obtain the preset value G of the input material 1 (That is: 20KG of material is expected to be put into each shaking, and the specific value can be set according to actual needs) and the operator can use experience according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com