High-speed switch

A high-speed switch and switch technology, which is applied to the power device inside the switch, contact vibration/shock damping, etc., can solve problems such as complex structures, and achieve the effects of expanding the scope of application, improving reliability, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

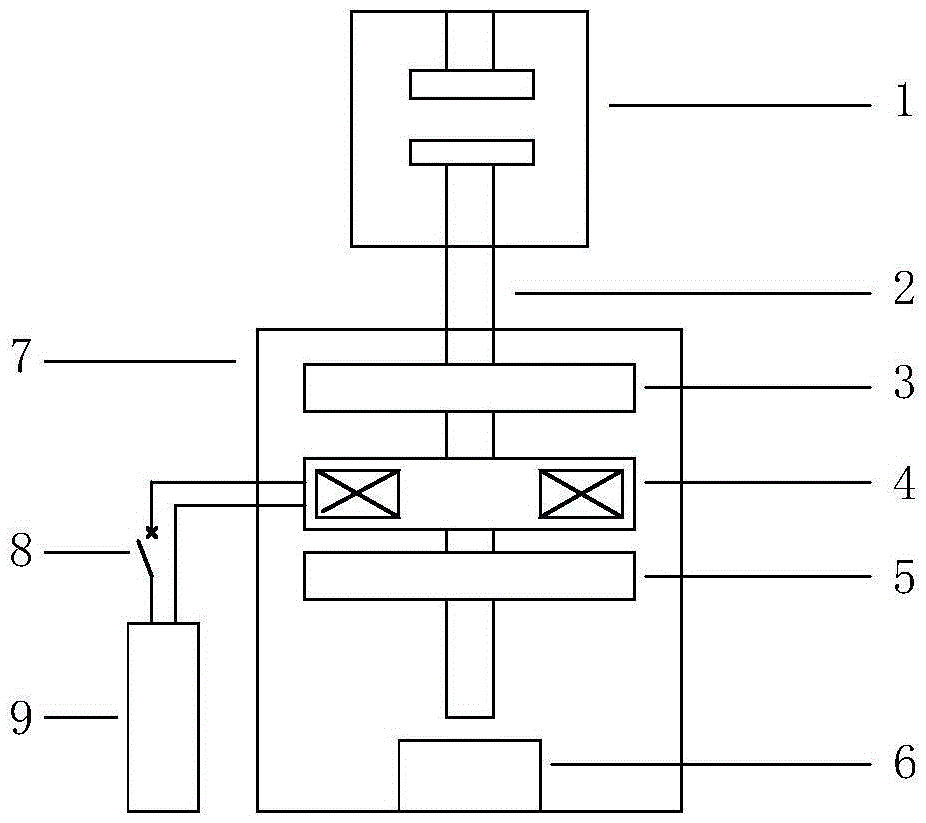

[0022] The present invention proposes a high-speed switch, such as figure 1 As shown, it consists of switch contact 1, connecting rod 2, repulsion operating mechanism, buffer 6, frame 7, closing and opening switch 8 and energy storage capacitor 9; the repulsion operating mechanism consists of opening repulsion plate 3, The repulsion coil 4 and the closing repulsion disc 5 are composed; the high-speed switch only needs one repulsion coil 4 to complete the closing and opening functions of the high-speed switch.

[0023] Wherein, the repulsion coil 4 is connected with the connecting rod 2, and the repulsion coil 4 will drive the connecting rod 2 to move together; the opening repulsion disk 3 and the closing repulsion disk 5 are respectively fixed on the frame 7. The repulsion coil 4 is placed b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap