Battery pack voltage equalization control circuit and battery management equipment

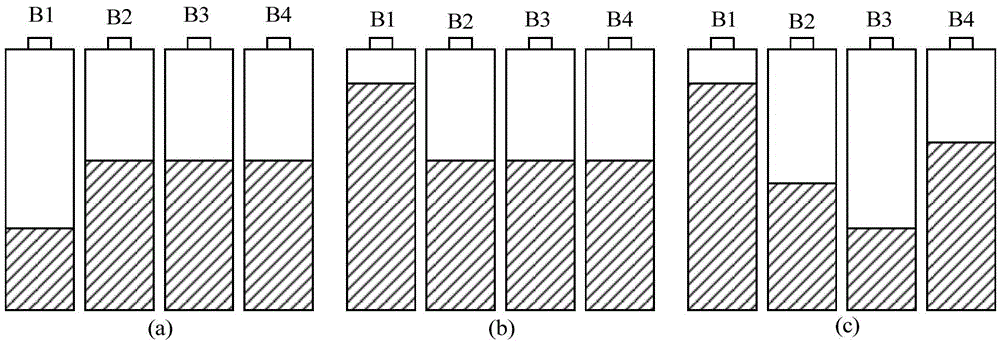

A voltage equalization circuit and voltage equalization technology, applied in charge equalization circuits, battery circuit devices, circuits, etc., can solve the problems of insufficient utilization of battery packs, complex control of energy transfer equalization strategies, and large energy loss, so as to improve charging and discharging. Utilize Efficiency, Maintain Consistency, Extend Service Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

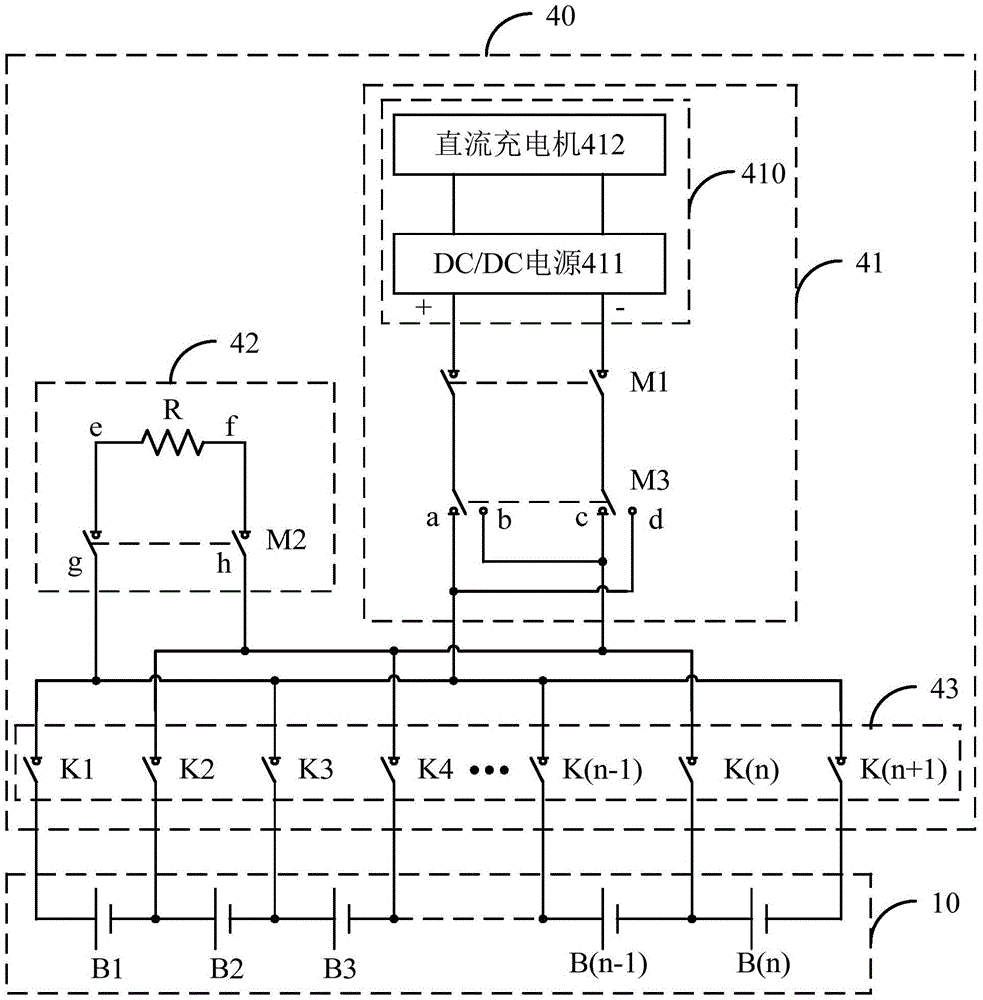

[0035] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

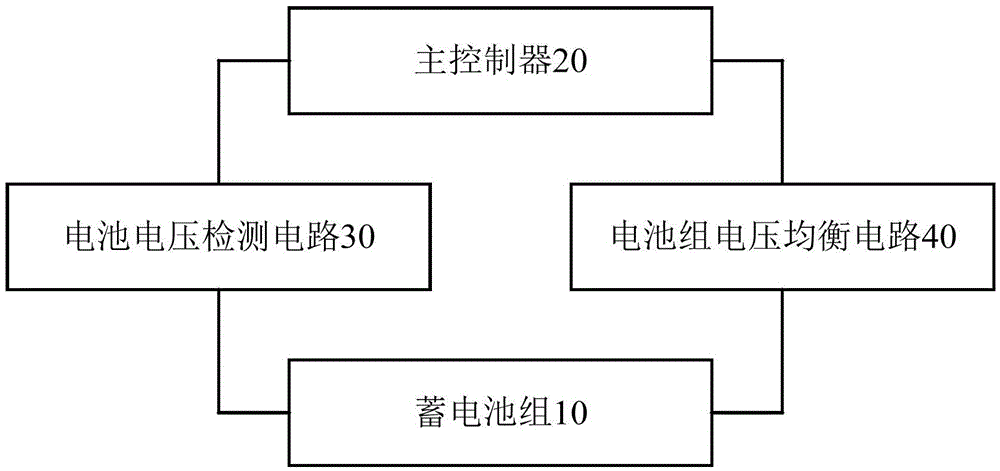

[0036] The battery pack voltage equalization control circuit of the present invention can be applied to the battery pack power supply system in the electric power, communication, electric vehicle and other industries, such as figure 2 As shown, the battery pack voltage balance control circuit in some embodiments of the present invention includes a battery pack 10 , a main controller 20 , a battery pack voltage detection circuit 30 and a battery pack voltage balance circuit 40 .

[0037] Those skilled in the art should understand that the battery pack 10 is composed of at least two batteries connected in series.

[0038] In the embodiment of the present invention, the detection input terminal of the battery voltage detection circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com