A method of manufacturing a printed board inlaid with a metal base

A manufacturing method and technology of printed boards, applied in printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the difficulty in ensuring the thickness of the dielectric layer between the metal base and the circuit layer, the difficulty in meeting the requirements for the control accuracy of the depth of the groove, and the prepreg Problems such as gong shape are needed to achieve the effect of reducing molding, simple production, and reducing the number of pressing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

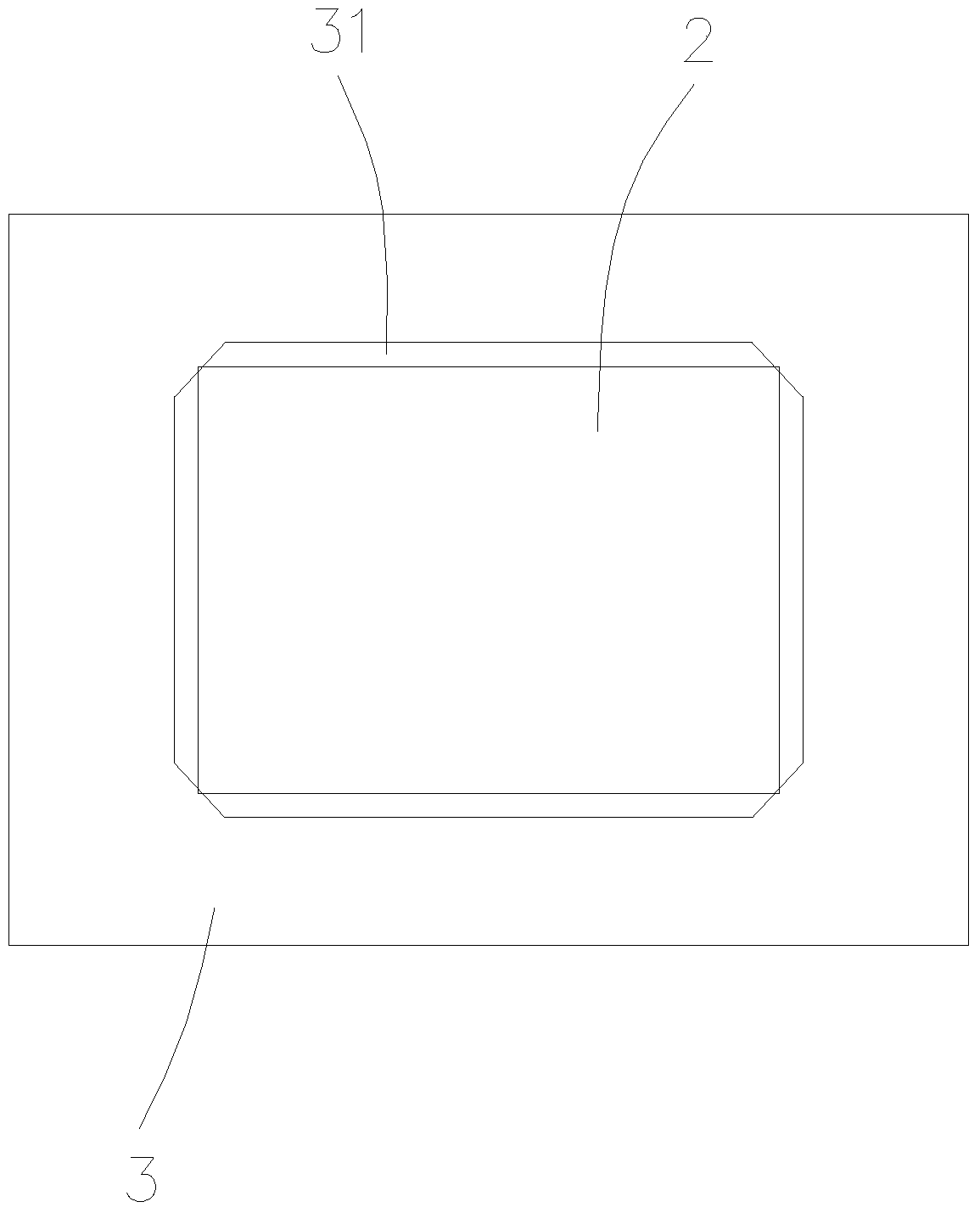

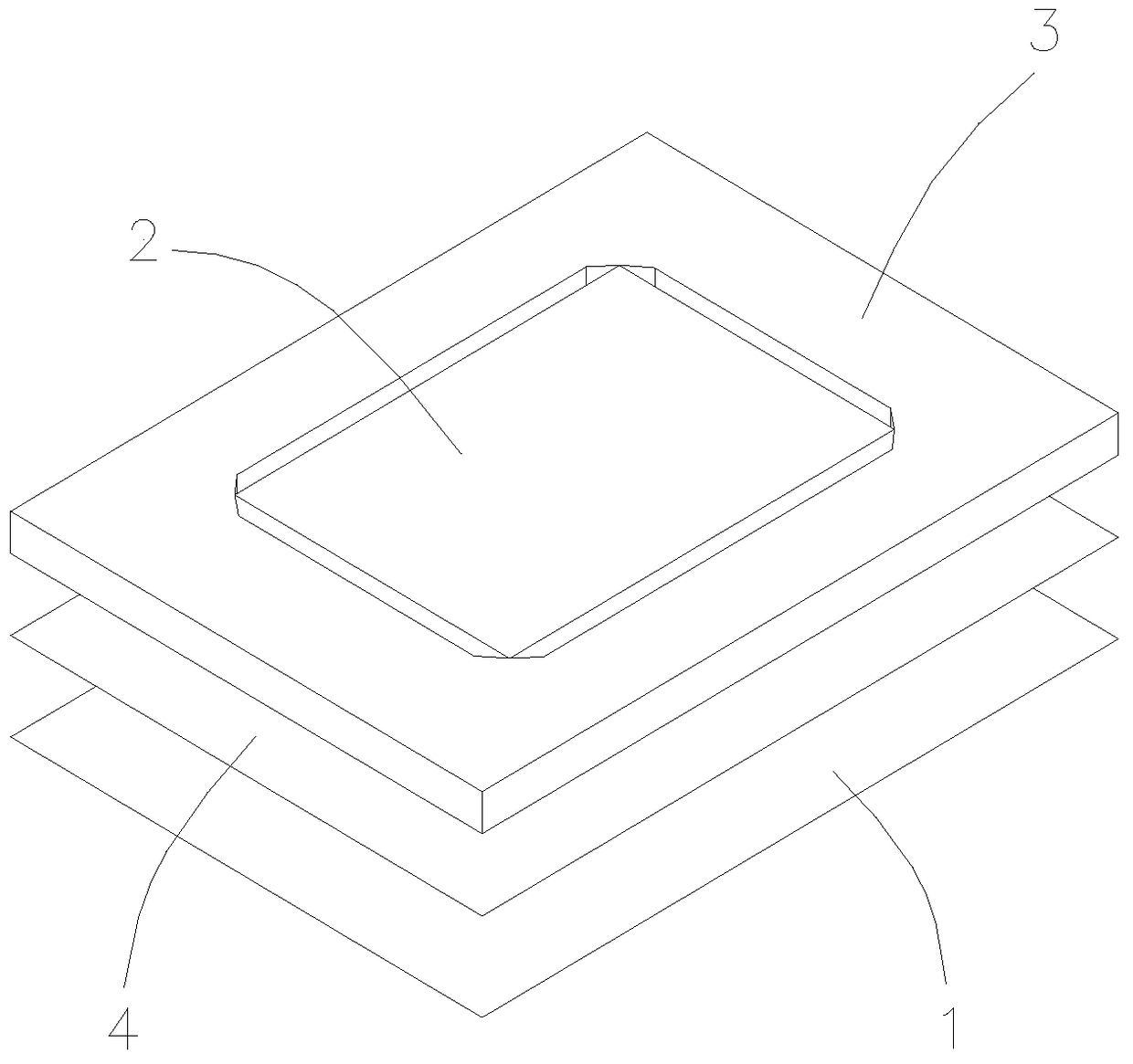

[0019] Such as figure 1 and figure 2 As shown, a method for manufacturing a printed board with a metal base, comprising:

[0020] (1) Complete the circuit production of the required circuit layer 1;

[0021] (2) Extrude or punch out the shape of the metal base 2 to be inserted;

[0022] (3) According to the shape and size of the metal base 2, punch out or punch out the corresponding embedded groove 31 on the printed board 3;

[0023] (4) Insert the metal base 2 into the embedding groove 31 of the printed board 3;

[0024] (5) Using the prepreg 4 to press the circuit layer 1 and the printed board 3 embedded with the metal base 2 together. When pressing, the prepreg 4 is located between the circuit layer 1 and the printed board 3, and the prepreg 4 is polymerized under high temperature and high pressure to form a solid polymer, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com