New seed crystal processing equipment

A technology for processing equipment and seed crystals, applied in the field of new seed crystal processing equipment, can solve the problem of low utilization rate of seed crystal masterbatch, and achieve the effects of improving adjustment accuracy and seed crystal processing efficiency, reducing investment and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] First, the novel seed crystal processing equipment according to the embodiment of the first aspect of the present invention will be described in detail below with reference to the accompanying drawings.

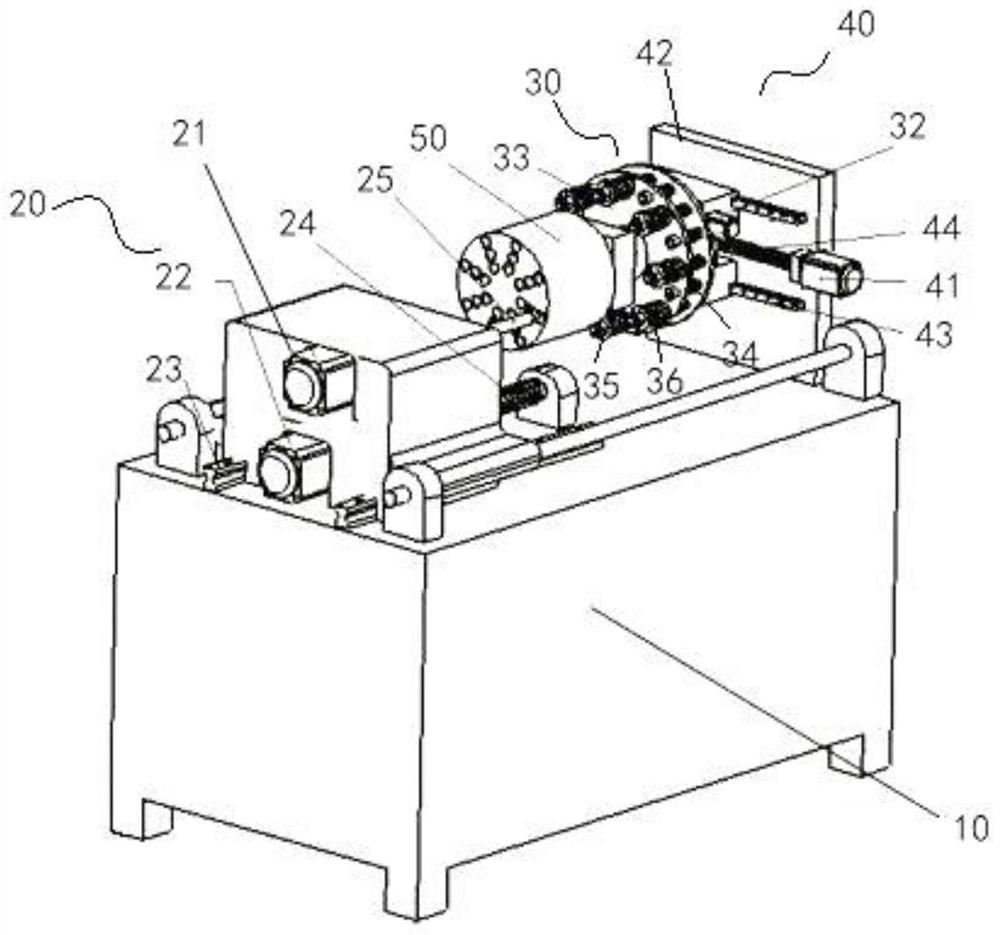

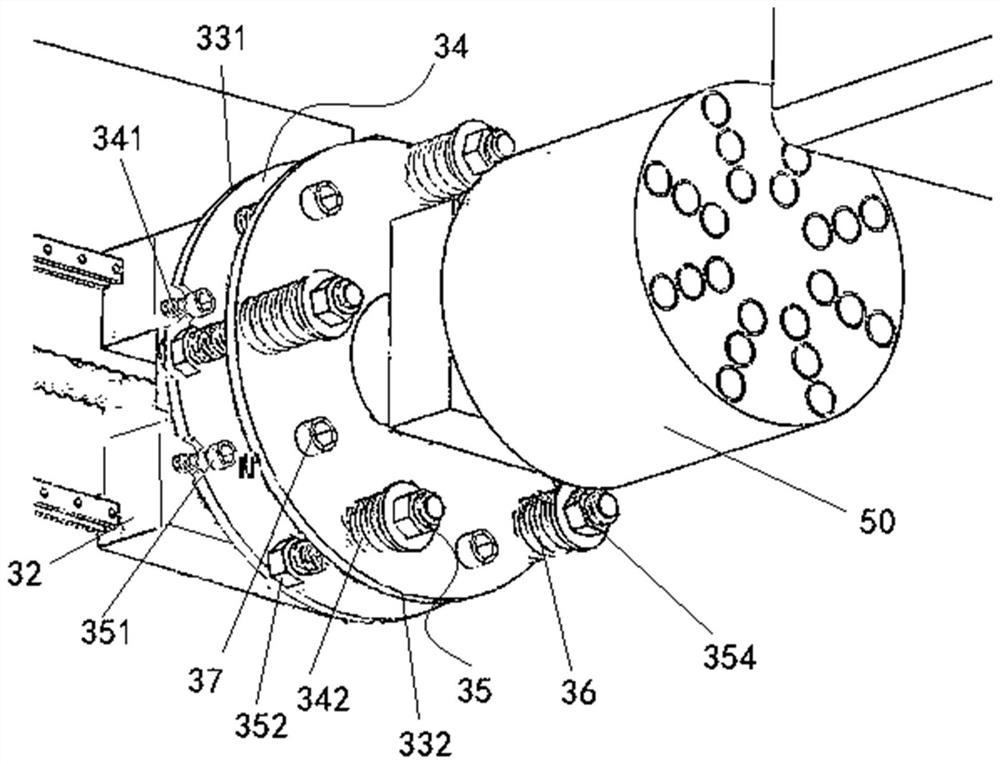

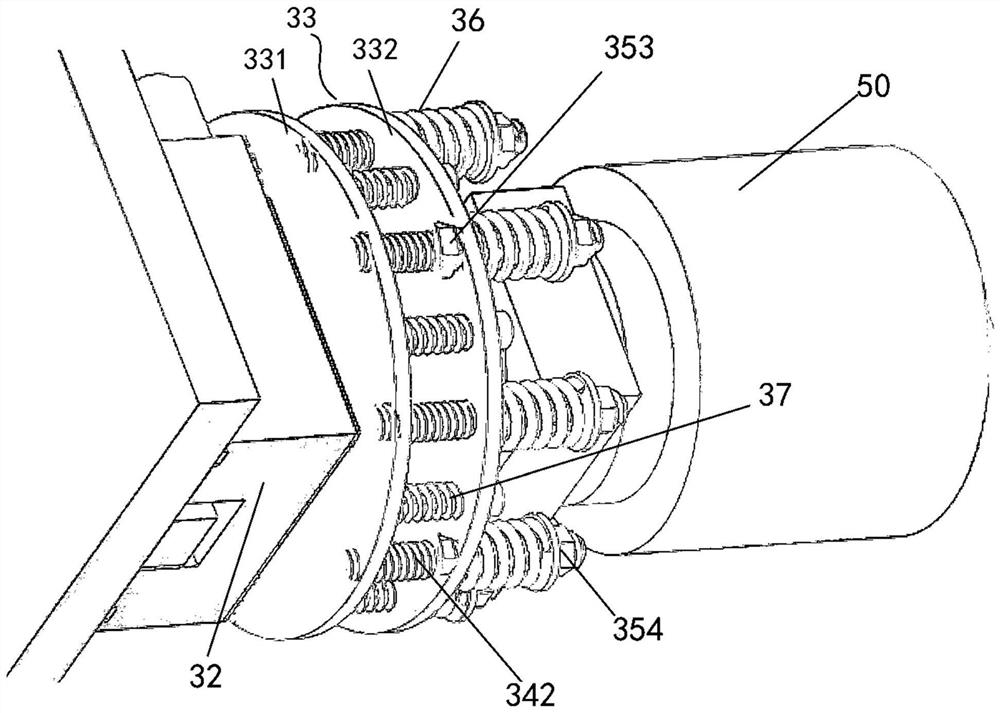

[0049] like figure 1 As shown, the novel seed crystal processing equipment according to the embodiment of the present invention includes a support platform 10 , a feeding device 20 , a rotating device 30 and a side shifting device 40 .

[0050] Specifically, the feeding device 20 is provided on the support platform 10 , the feeding device 20 includes a feeding assembly and a processing assembly connected with the feeding assembly, and the processing assembly includes a first driving mechanism 21 , and a hollow core connected with the first driving mechanism 21 the drill pipe 25, the first drive mechanism 21 drives the drill pipe 25 to rotate to process the seed crystal masterbatch 50, the feed assembly includes a second drive mechanism 22, and the second drive mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com