Carbon material dispersed film-forming composition

一种碳材料、分散膜的技术,应用在涂层等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0260] Synthesis examples and examples are given below to describe the present invention more specifically, but the present invention is not limited to the following examples. In addition, each measurement apparatus used in the Example is as follows.

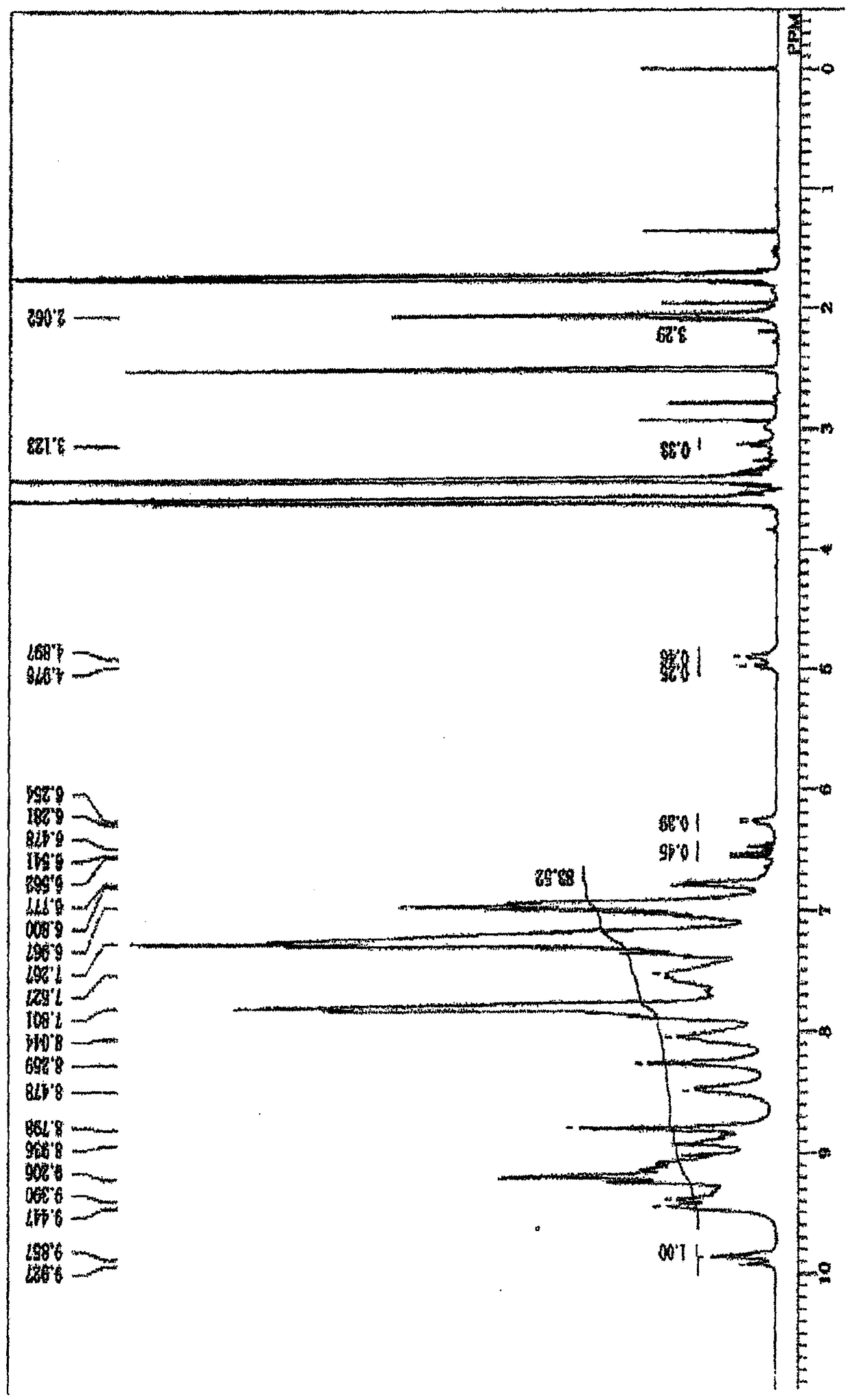

[0261] [ 1 H-NMR]

[0262] Device: Varian NMR System 400NB (400MHz)

[0263] JEOL-ECA700(700MHz)

[0264] Determination solvent: DMSO-d6

[0265] Reference material: Tetramethylsilane (TMS) (δ0.0ppm)

[0266] [GPC]

[0267] Device: HLC-8200GPC manufactured by Tosoh Co., Ltd.

[0268] Column: Shodex KF-804L+KF-805L

[0269] Column temperature: 40°C

[0270] Solvent: tetrahydrofuran (hereinafter abbreviated as THF)

[0271] Detector: UV (254nm)

[0272] Calibration curve: standard polystyrene

[0273] [Ellipsemeter]

[0274] Device: Multiple incident angle spectroscopic ellipsometer VASE made by JA Woollam Japan

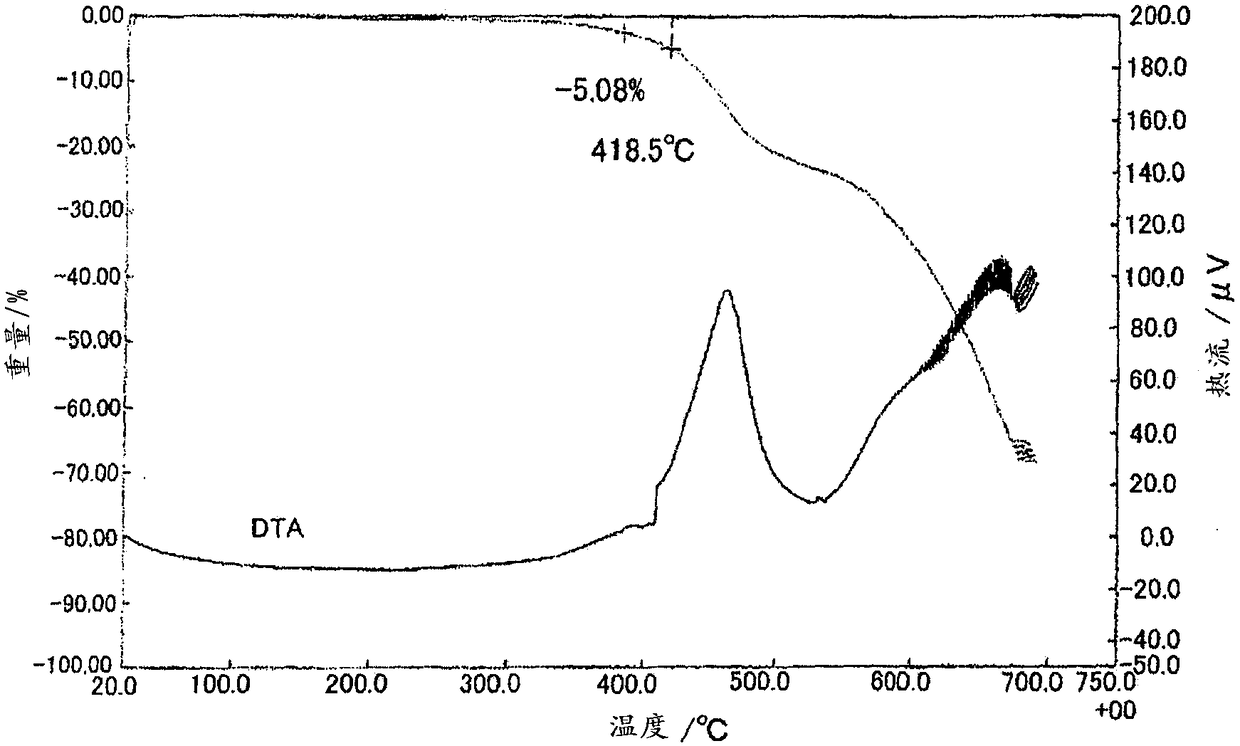

[0275] [Differential thermal balance (TG-DTA)]

[0276] Device: TG-8120 manufactured by Rigaku Co., Ltd....

Synthetic example 1

[0288] [Synthesis Example 1] Synthesis of HB-TmDA

[0289] [chemical 17]

[0290]

[0291] In nitrogen, add 456.02g of DMAc to a 1000mL four-neck flask, cool it to -10°C with an acetone-dry ice bath, add 2,4,6-trichloro-1,3,5-triazine[1]( 84.83 g, 0.460 mol, manufactured by Evonik Degussa) and dissolved. Then, m-phenylenediamine [2] (62.18 g, 0.575 mol) and aniline (14.57 g, 0.156 mol) dissolved in DMAc304.01 g were added dropwise. After dropping, stir for 30 minutes, put the reaction solution for use, add 621.85 g of DMAc into a 2000 mL four-neck flask, heat the reaction vessel to 85 °C with an oil bath in advance, and then use a feed pump to drop the above solution for 1 hour. The reaction solution was stirred for 1 hour to polymerize.

[0292] Then, aniline (113.95 g, 1.224 mol) was added, and the reaction was terminated after stirring for 1 hour. After cooling to room temperature with an ice bath, triethylamine (116.36 g, 1.15 mol) was added dropwise, stirred for 30...

preparation example 1

[0299] 4040 g of HB-TmDA obtained in Synthesis Example 1 was dissolved in 153.6 g of cyclohexanone and 6.4 g of deionized water to prepare a 20% by mass solution (hereinafter referred to as HB-TmDA40V).

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com