Breaking device for cobs

A technology of corn cobs and charging buckets, which is applied in applications, threshing equipment, agricultural machinery and tools, etc., can solve the problems of reduced work efficiency and increased workload of operators, and achieves reduced work intensity, stable fixation, and increased automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

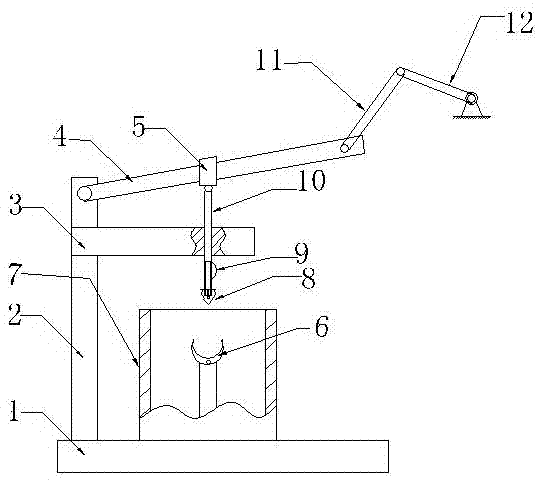

[0016] The reference signs in the drawings of the description include: base 1, vertical rod 2, fixed plate 3, pressure rod 4, slider 5, claws 6, charging barrel 7, petal-shaped expansion body 8, handle 9, broken rod 10, connecting rod 11, crank 12.

[0017] Example basic reference figure 1 Shown:

[0018] The cracking device for corn cobs in this program includes a frame, on which a base 1 is arranged, on which the base 1 is fixedly connected with a vertical bar 2 and a charging barrel 7, and the vertical bar 2 is respectively connected with a pressure bar from top to bottom 4 and the fixed plate 3, the depression bar 4 and the vertical bar 2 are connected together by a rotating shaft screw, so that the depression bar 4 can rotate around the rotating shaft, and the depression bar 4 is hinged with a connecting rod 11 at an end away from the vertical rod 2, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com