A finishing mold with a top pressure device

A pressurizing device and finishing technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., to achieve the effect of improving applicability, improving cold working accuracy, and good workpiece forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

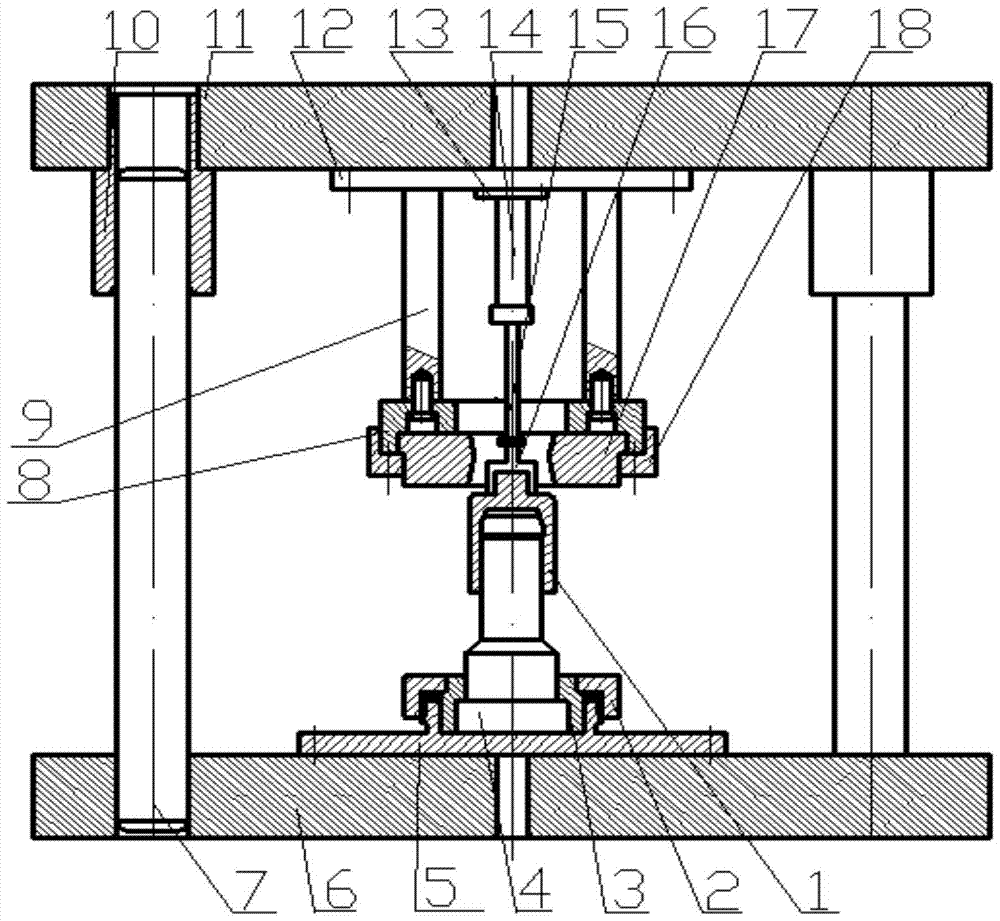

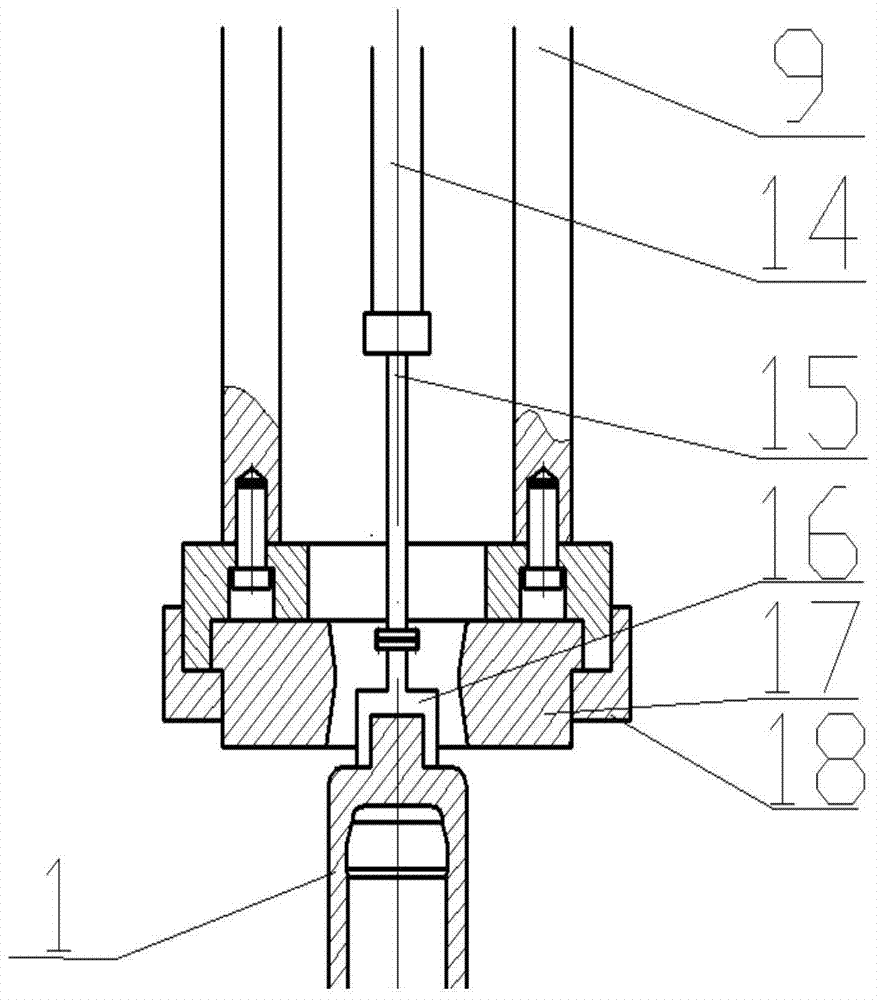

[0025] Attached below figure 1 and 2 And specific embodiment further specification of the present invention:

[0026] A finishing mold with a top pressing device, comprising a finishing mold and a top pressing device; Die 4, punch cover 3, patrix guide upper plate 12, patrix guide column 9 and patrix guide base plate 8; upper formwork 11 and lower formwork 6 corresponding positions are provided with round through holes, guide pillars 7 are four, guide The column 7 longitudinally runs through the circular through hole at the corresponding position of the upper template 11 and the lower template 6, and the guide column 7 passes through the guide sleeve 10 in the upper template 11; There are three mold guide columns 9, one end of the upper mold guide column 9 is fixed on the upper mold guide plate 12 through a screw B, and the other end of the upper mold guide column 9 is connected with the upper mold guide base plate 8 through a bolt C; 17 is fixed on the upper mold guide bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com