Decomposition Method of Full Complement Cylindrical Roller Bearing Based on Spiral Test Rack

A technology of cylindrical roller bearing and test frame, which is applied to workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of scratches on the surface of the rollers and raceways, and the lack of relevant information on bearing disassembly, etc. To achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

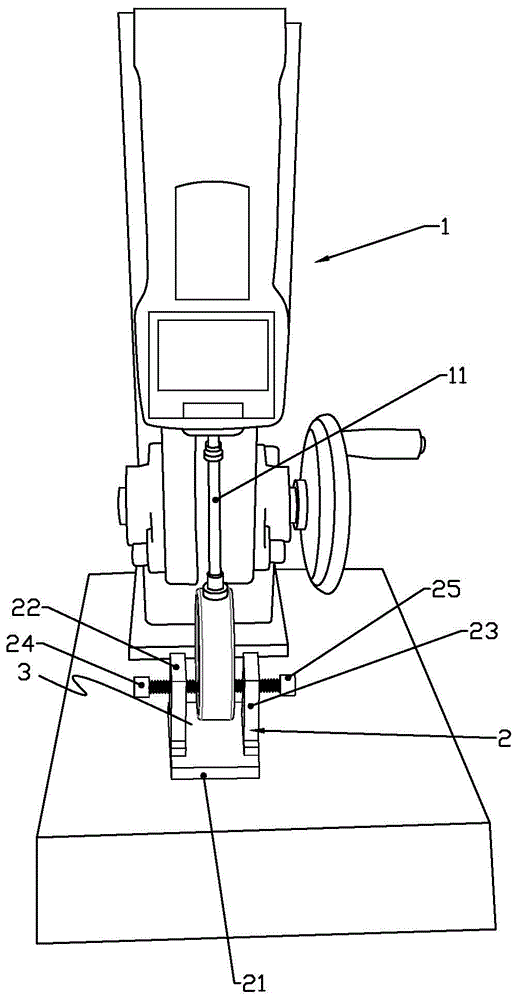

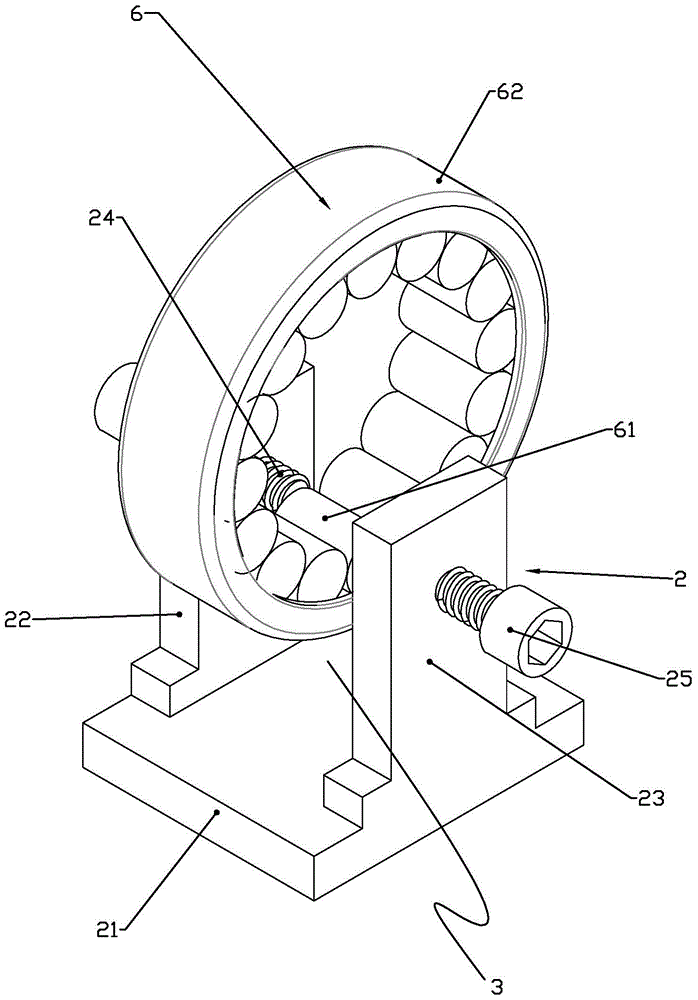

[0017] See attached figure 1 And attached figure 2 , a method for disassembling a full complement cylindrical roller bearing based on a spiral test frame disclosed by the present invention, the method is carried out in the following steps:

[0018] Step 1, place the full complement cylindrical roller bearing 6 on the fixture 2 of the spiral test frame 1, and the fixture 2 clamps and fixes the cylindrical roller 61 of the full complement cylindrical roller bearing 6 along the roller axis, and makes The bearing outer ring 62 of the full complement cylindrical roller bearing 6 is suspended;

[0019] Step 2, the pressing rod 11 of the spiral test frame 1 presses the outer ring 62 of the bearing, so that the cylindrical roller 61 is separated from the raceway of the outer ring 62 of the bearing, and the measurement of the extrusion force of the roller 61 is completed. The direction of the pushing force of the pressing rod 11 is It is located on the same straight line as the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com