Biofuel sheet press

A biofuel and curved sheet technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of small gaps, unusable heat energy of straw, and unsmooth airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

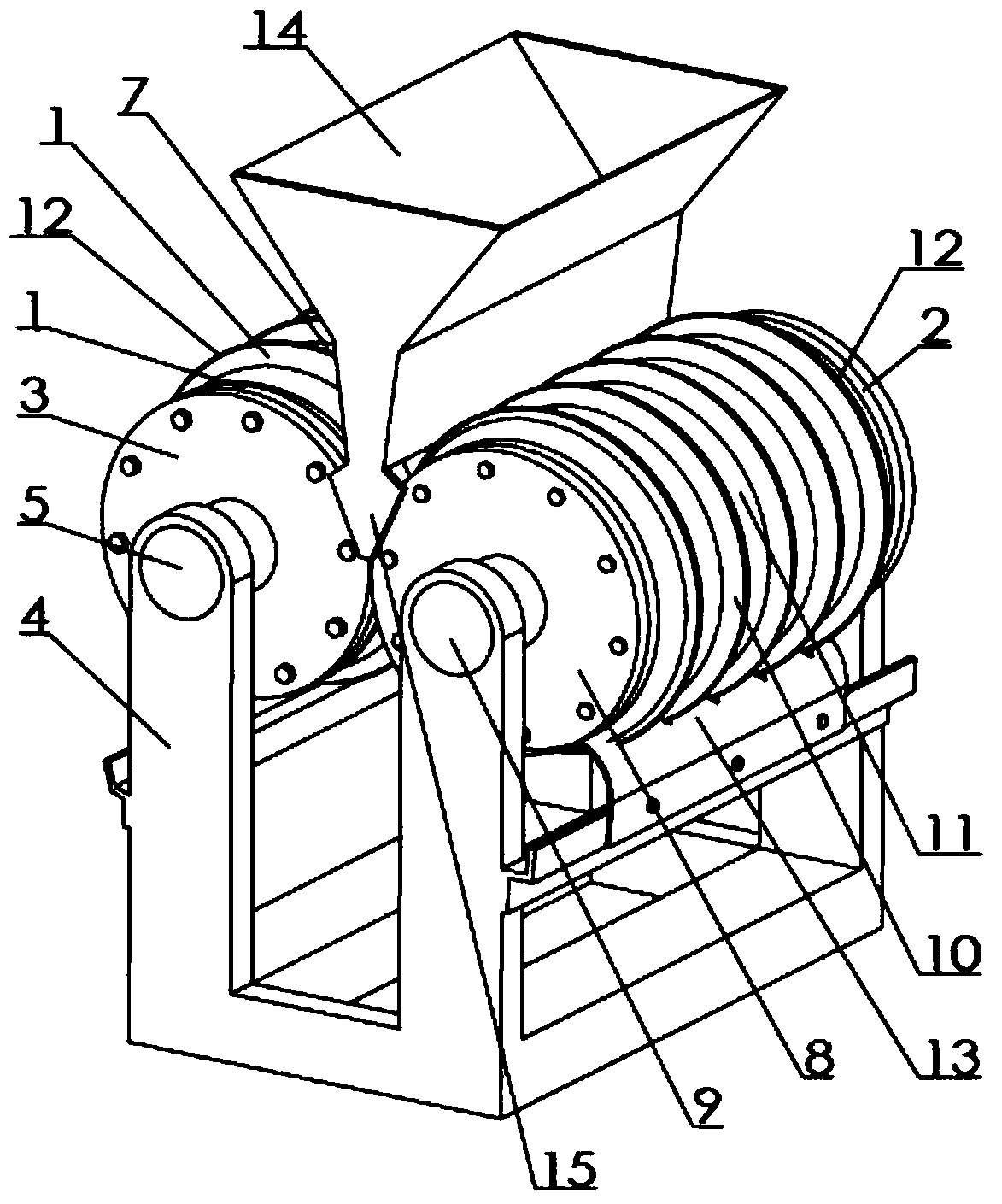

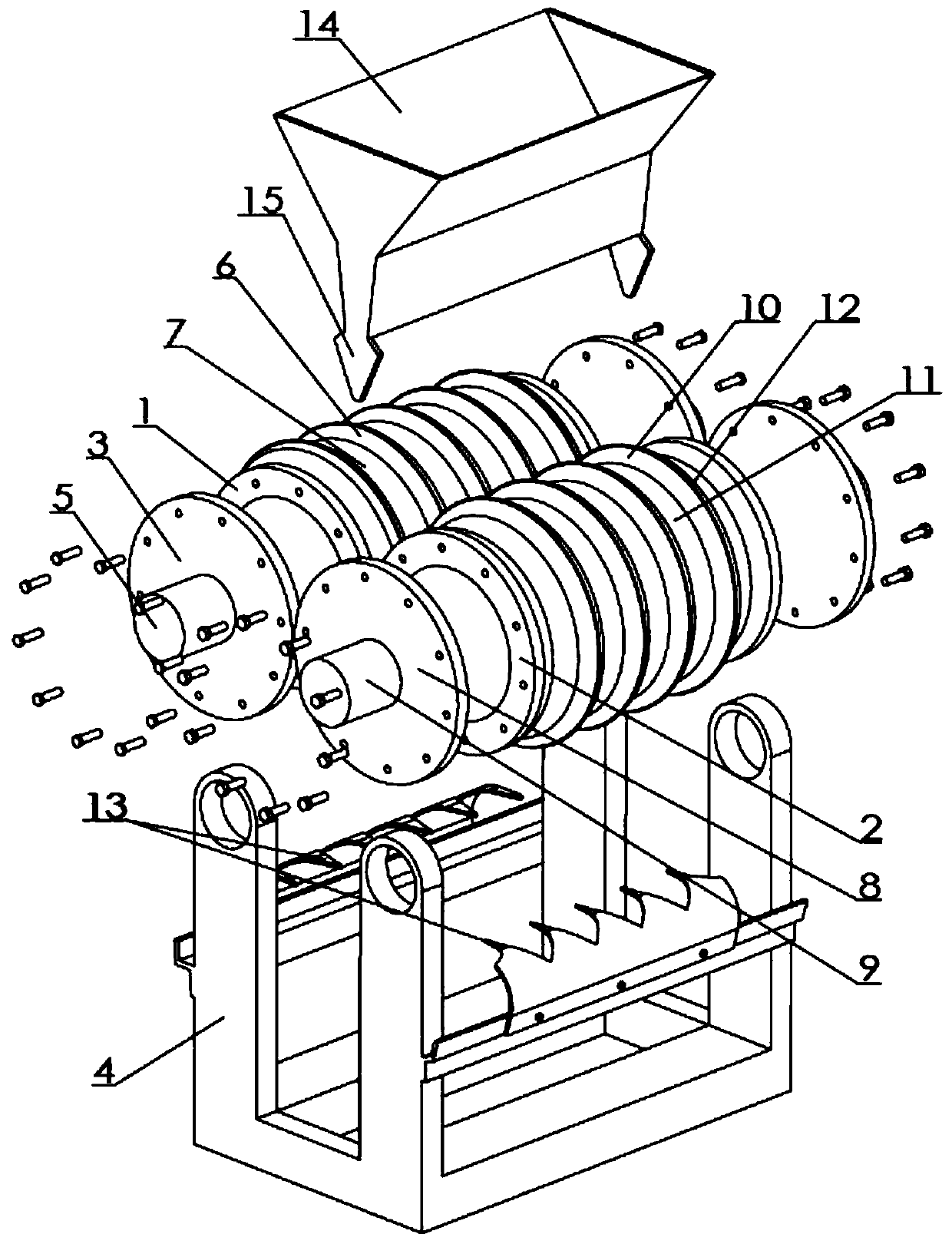

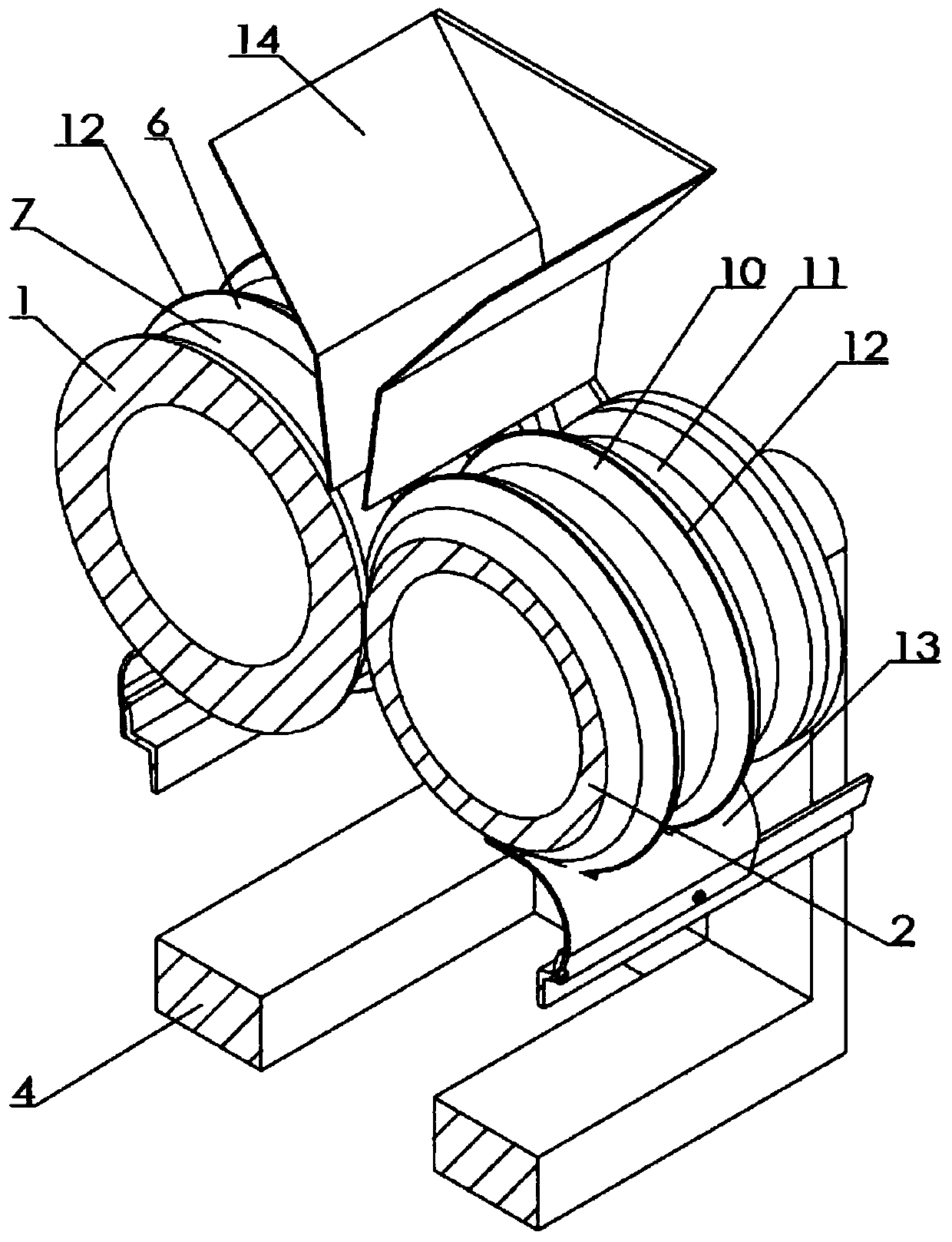

[0012] Examples of the present invention figure 1 , 2 As shown in . and 3, the biofuel curved plate pressing device is provided with a main roller 1 and a synchronous roller 2 that are axially parallel and synchronously rotated in opposite directions; the main roller is cylindrical, and the two ends of the main roller are respectively fixedly connected with main end plates 3 , the two main end plates are connected with the main drive shaft 5 coaxial with the main roller and connected to the bracket 4, and the surface of the main roller is provided with circumferential main wave peaks 6 and circumferential main wave troughs 7 arranged axially at intervals; The synchronous roller is cylindrical and has the same length as the main roller. The synchronous roller is parallel to the axis of the main roller. The two ends of the synchronous roller are respectively fixedly connected with the synchronous end plate 8, and the synchronous end plate is fixedly connected with the synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com