Supporting frame for front wind window frame lower cross beam

A front wind window frame and support frame technology, used in windows, windshields, transportation and packaging, etc., can solve the problems of increased failure rate, easy deformation, low welding efficiency, etc. Displacement deformation and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

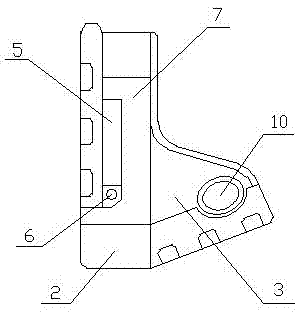

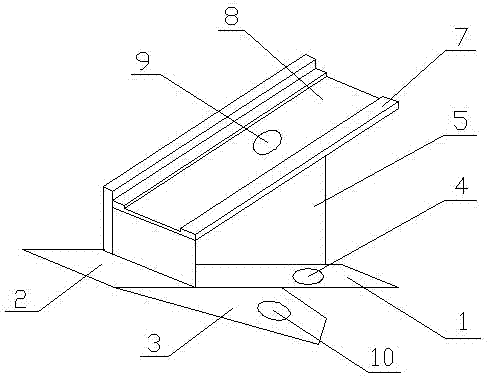

[0012] The bottom plate 1 is respectively connected with the welding plate 2, the bent welding plate 3, and the fixing block 5, the fixing hole 4 is set on the bottom plate 1, the side lamp outlet hole 10 is set on the bending welding plate 3, and the fixing block 5 is connected with the bracket slope 7 , A circular hole 6 is provided on the fixed block 5, a positioning groove 8 is provided on the support slope 7, and a mounting hole 9 is provided on the positioning groove 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com