Flow guide disk for pressure-resistant disc-tube type membrane component

A disc-tube membrane and guide plate technology, applied in the field of guide plate, can solve the problems of diaphragm damage and inconvenient installation of the guide plate, and achieve the effects of reducing pressure, saving manpower, and enhancing pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

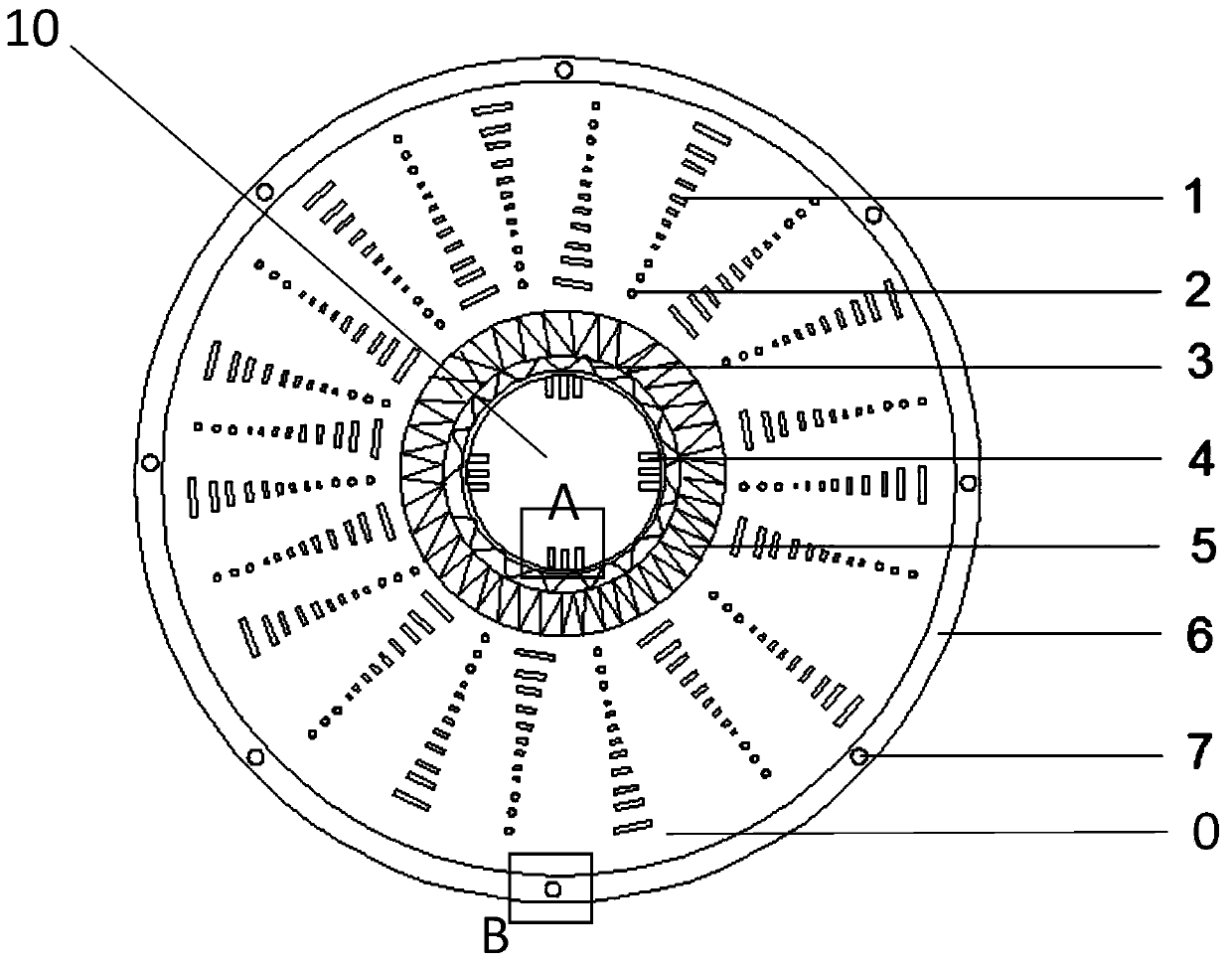

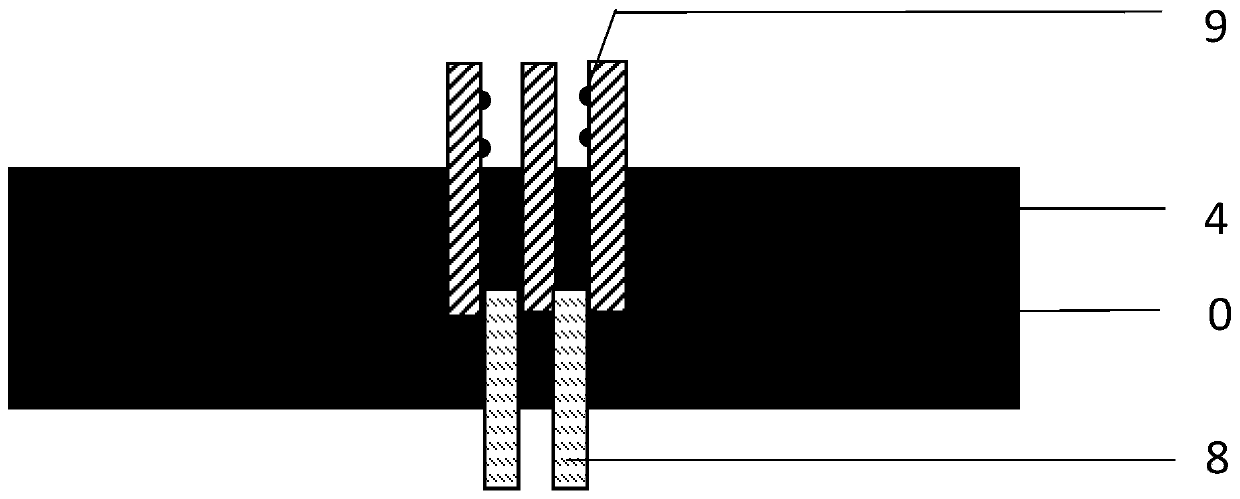

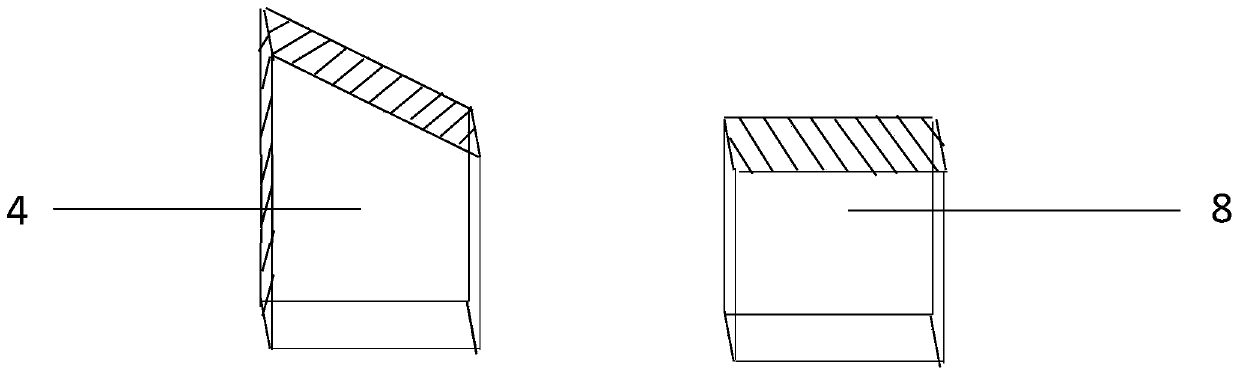

[0019] This implementation case discloses a deflector plate for a pressure-resistant disc-tube membrane module, such as figure 1 , figure 2 As shown, the deflector includes: a deflector body O, a central hole 10 is provided at the center of the deflector body O, and small fences that can be inserted into each other are provided around the central hole 10 on the front and back of the deflector Distributed around the center hole 10 of the main body of the deflector plate are three identical right-angled trapezoidal small fences 4 on the front, and two rectangular parallelepiped small fences 8 that can be sealed and inserted with 4 on the reverse side, and the adjacent front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com