Food sterilizing and packaging all-in-one machine

An all-in-one machine and food technology, applied in the field of food sterilization and packaging all-in-one machines, can solve the problems of single function, low production efficiency, lack of availability, etc., and achieve the effect of strong automation, improving production efficiency, and ensuring safety and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

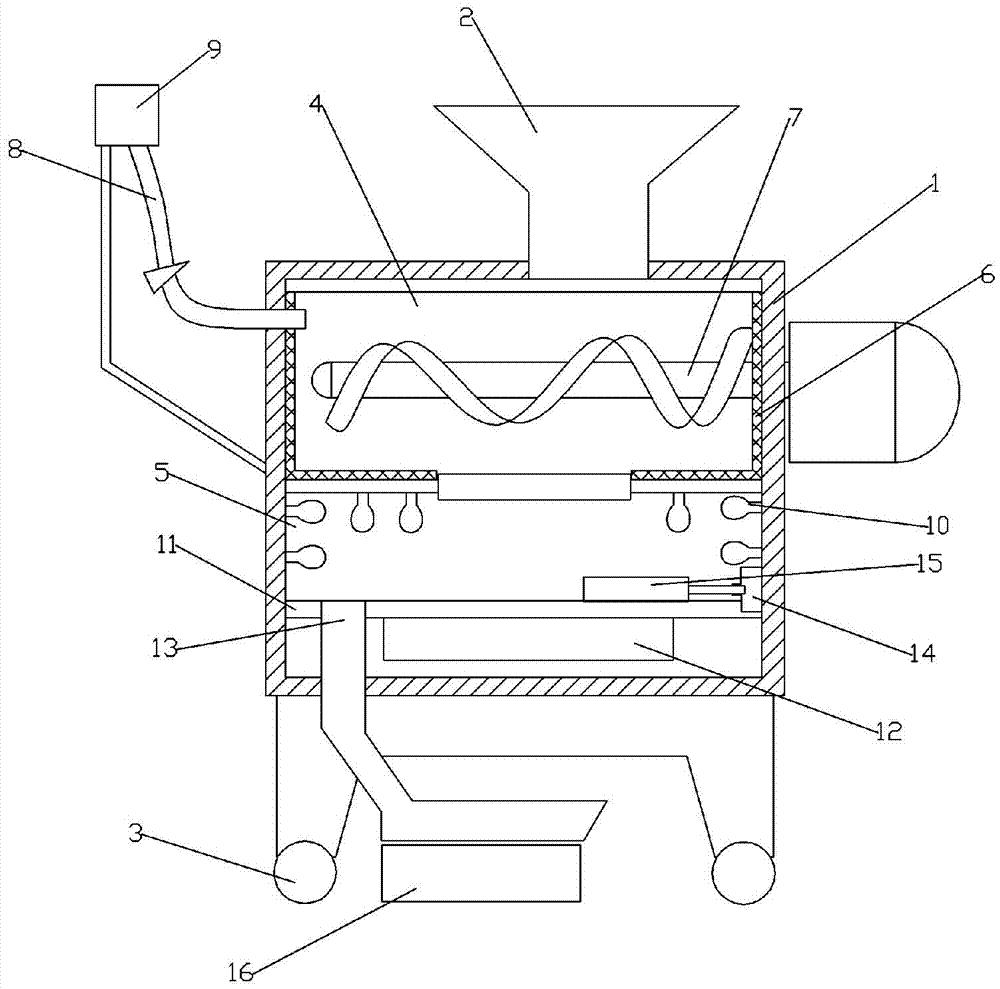

[0012] The reference numerals in the accompanying drawings of the description include: chassis body 1, feeding hopper 2, universal wheel 3, mixing chamber 4, weighing chamber 5, food plastic film 6, stirring shaft 7, seasoning conveying conduit 8, seasoning bag 9, Sterilization lamp 10, base plate 11, pressure sensor 12, blanking port 13, cylinder 14, push plate 15, sealing machine 16.

[0013] The embodiment is basically as attached figure 1 As shown: an integrated machine for food sterilization and packaging, including a cabinet body 1 and a feeding hopper 2 arranged on the top of the cabinet body 1. Support columns are provided at the four corners of the bottom of the cabinet body 1, and universal wheels 3 are installed on the support columns. The inside of the cabinet body 1 is provided with a mixing chamber 4 and a weighing chamber 5 communicating with the mixing ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com