Shock-resistant freight transporting box

A technology for cargo transportation and shock parts, which is applied in the field of shock-resistant cargo transport boxes, can solve problems such as unfavorable fresh-keeping of fresh agricultural products, poor shock resistance, bumps, etc., and achieve good heat preservation and moisturizing effect, prevent damage, and good shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

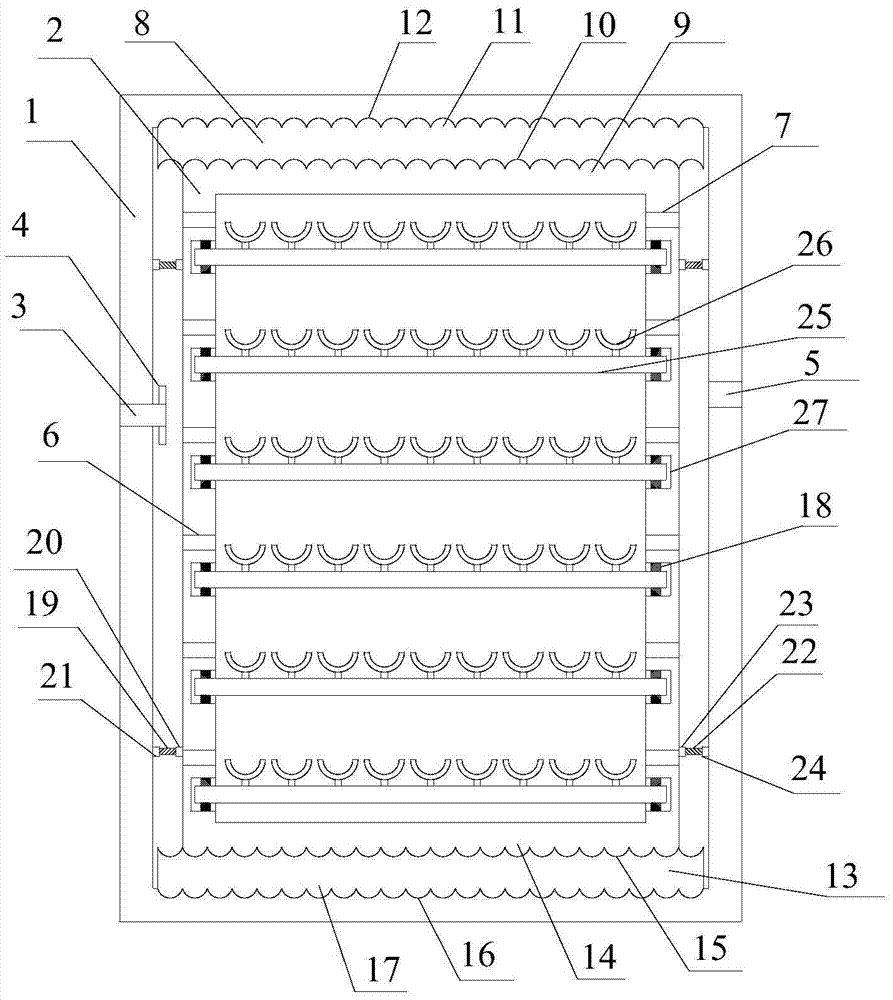

[0016] refer to figure 1 , the present invention proposes an anti-seismic cargo transport box, comprising an outer box body 1, an outer box door hinged with the outer box body 1, an inner box body 2 arranged in the outer box body 1, and an inner box door hinged with the inner box body 2 , control device, wherein:

[0017] One side of the outer box body 1 is provided with an air intake pipe 3, and one end of the air intake pipe 3 located in the outer box body 1 is provided with a plurality of air nozzles 4, and a flow valve is arranged in the air nozzle 4, and the plurality of air nozzles 4 are evenly distributed on the air intake pipe. 3 On the circumference centered on the central axis, an air outlet pipe 5 is provided on the side of the outer box body 1 away from the air inlet pipe 3 .

[0018] Air inlet holes 6 are distributed on the side of the inner box body 2 close to the air inlet pipe 3, air outlet holes 7 are distributed on the side of the inner box body 2 near the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com