Splice welding device for vehicle frame used for engineering machinery and splice welding method for vehicle frame

A technology for construction machinery and frame, which is applied to the frame tailor-welding device for construction machinery and its tailor-welding field, can solve the problems of low production efficiency, missed joints, etc., and achieves less floor space, less workshop dependence, and less capital investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

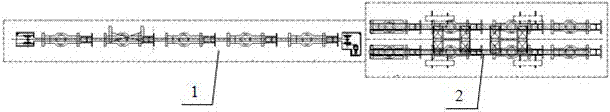

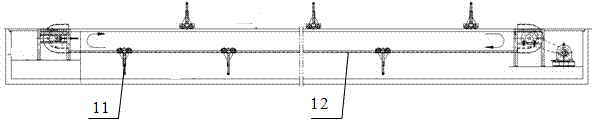

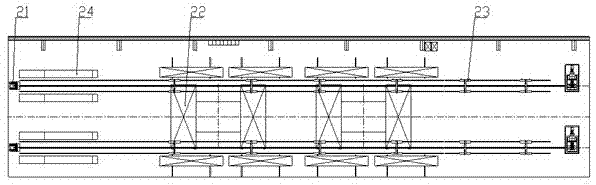

[0018] like figure 1 As shown in the figure, the frame tailor-welding device for construction machinery includes a joint assembly line 1 and a welding assembly line 2; the assembly point assembly line 1 and the welding assembly line 2 are equally divided into several stations, which can be set according to actual needs. Generally, the assembly point assembly line 1 It is divided into five stations, the welding line 2 is divided into four stations, and the welding line 2 has two sets, which is a two-line parallel structure, which can realize the balance of splicing points and welding processes; such as figure 2 As shown, the assembly line 1 includes a transfer trolley 11 and a circulating line body 12, and the transfer trolley 11 is connected with the circulating line body 12; such as image 3 As shown, the welding line 2 includes a reciprocating line body 21, a turni...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap