Steel hydraulic river sluice

A kind of sluice, hydraulic technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve the problems of geographical restrictions, high cost of pneumatic gates and rubber dams, poor safety, etc., to achieve simple foundation, light weight, strong earthquake resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

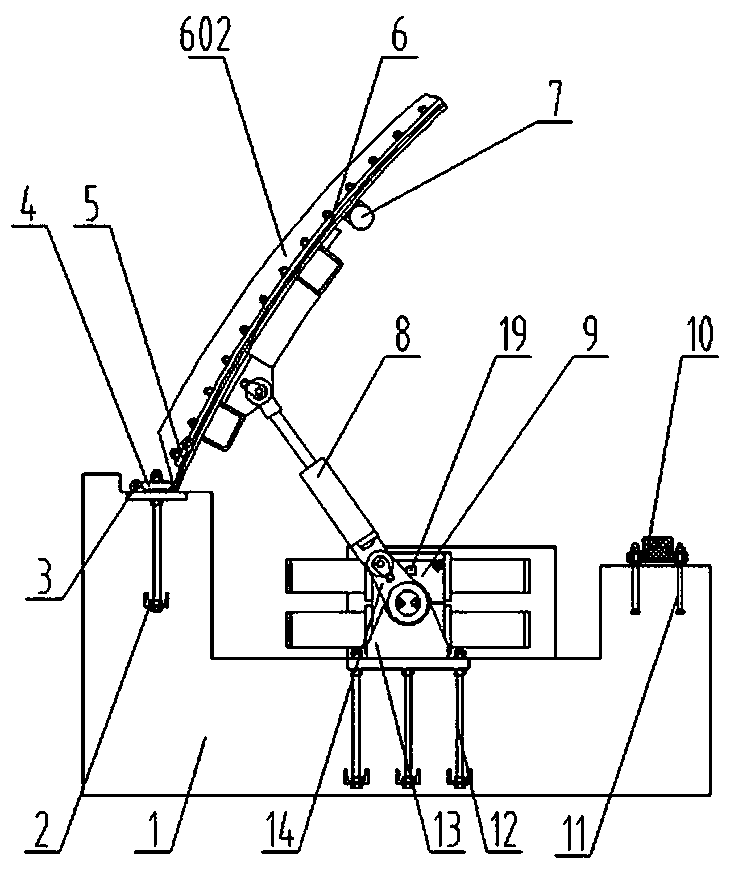

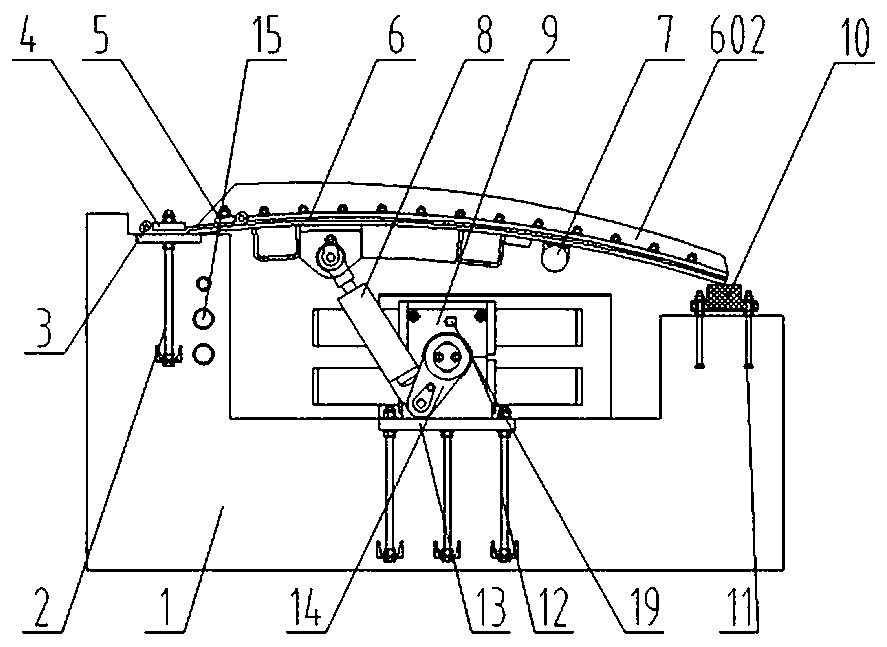

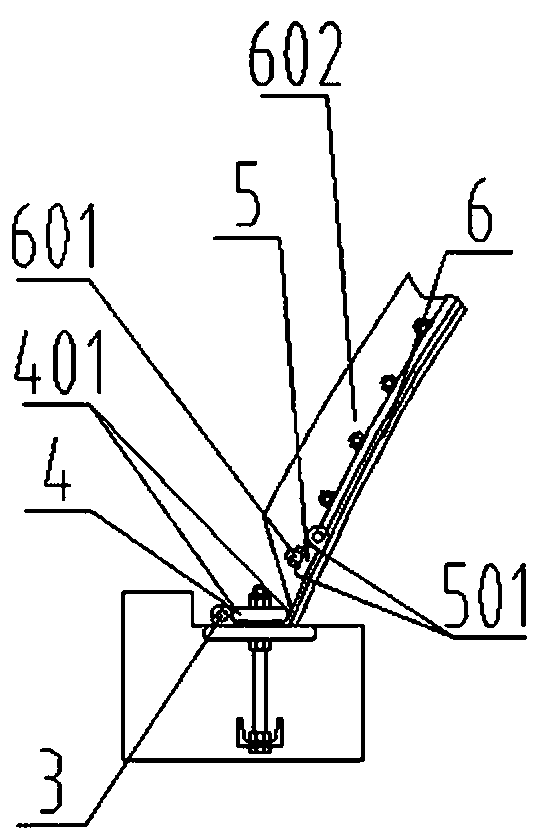

[0038] Such as Figure 1-9 As shown, a steel hydraulic barrage provided by the present invention includes a control system and a plurality of gate units;

[0039] Such as Figure 9 As shown, the control system is a computer, which is arranged in the computer room beside the river. The control system runs with management and control software. The software flow chart is shown in Figure 7 .

[0040] The control system includes an A / D conversion module (101), a data receiving module (102), a data sending module (103), an information processing module (104), a database (105), and an information statistics display module (106); After the system is initialized, the data receiving module (102) is on standby, and receives the information from the sensor (7) and the limit switch (19) at any time through the communication interface, and converts the analog signal through the A / D conversion module (101). converted into a digital signal, transmitted to the data receiving module (102), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com