Lifting check curtain structure of seal box

A technology of sealing boxes and curtains, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve the problems of difficulty in replacing curtains, insufficient sealing performance of fire plugs, and blocking of lifting curtains, so as to achieve the replacement of curtains. Fast and convenient, eliminates the possibility of jamming, and improves the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

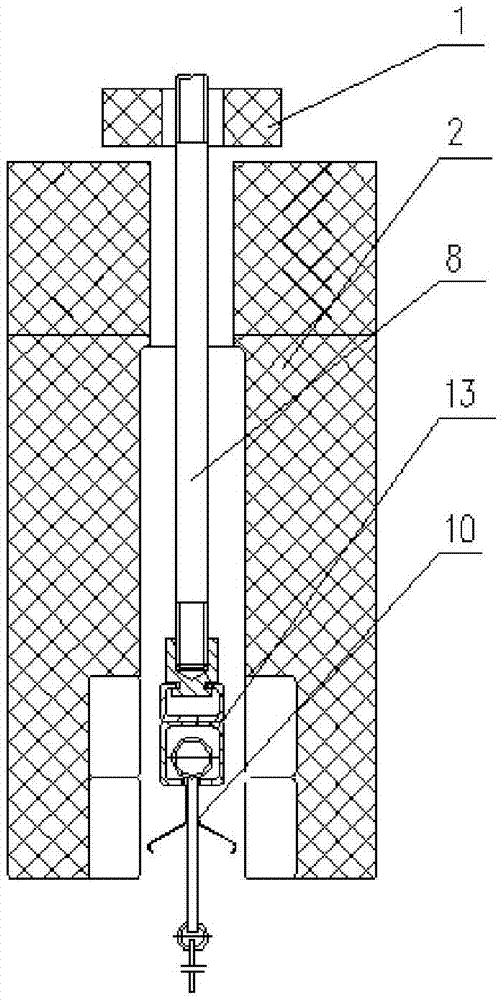

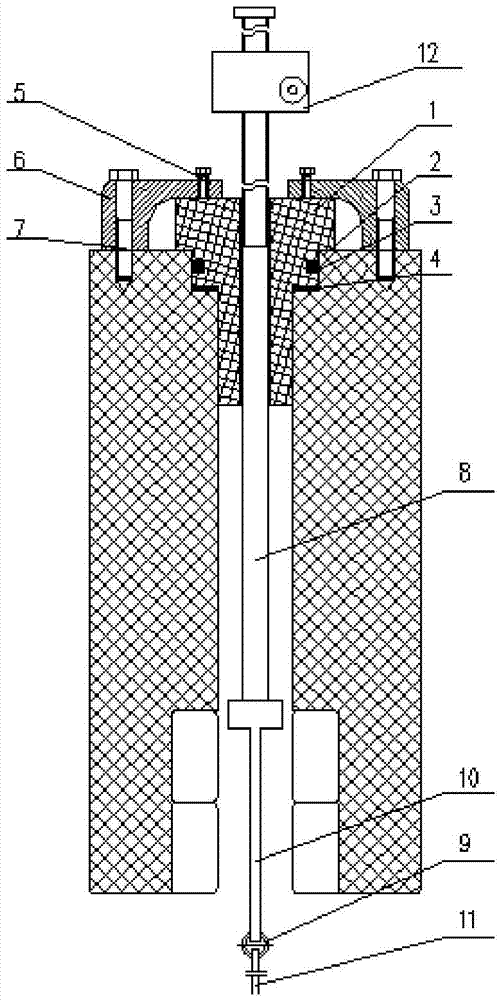

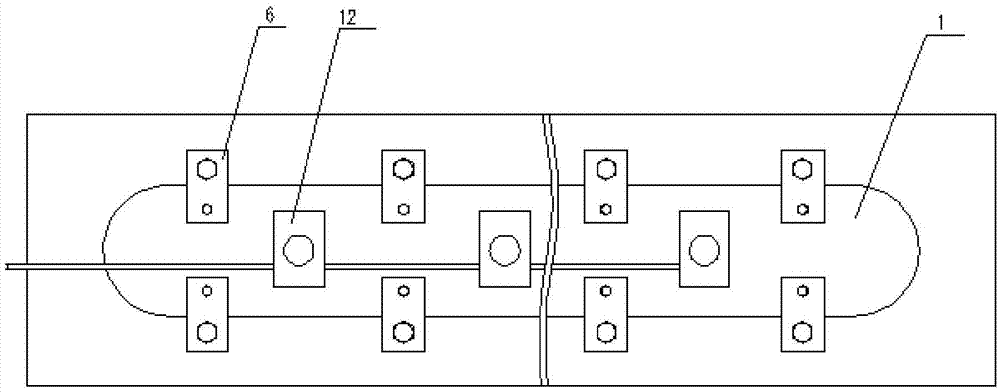

[0013] Such as figure 2 , image 3 As shown, a sealed box lifting curtain structure includes a sealed box cover 2, a fire stopper 1 is installed in the stepped hole of the sealed box cover 2, and the step hole of the sealed box cover 2 is connected to the fire stopper 1. An asbestos pad 4 is placed between them, the square asbestos rope 3 is embedded in the annular sealing groove of the fire stopper 1, the pressure plate 6 is connected with the upper cover 2 of the sealing box by bolts 7, the pressure plate 6 is placed on the top of the fire stopper 1, and the Tighten the screw 5 to tightly compact the fire stopper 1, asbestos pad 4 and the upper cover 2 of the sealing box on the stepped hole of the upper cover 2 of the sealing box. The upper end is connected with a lifter 12, and the lower end of the curtain lifting rod 8 is installed with a curtain 10, a curtain plate 11, and a pressure ring 9; when replacing the curtain 10, loosen the bolt 5 above the fire plug 1 and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com