System and method for recovering ethylene from high propylene light hydrocarbons or methanol-to-propylene product gas

A technology for producing propylene and high propylene light hydrocarbons from methanol is applied in ethylene production, hydrocarbon purification/separation, chemical instruments and methods, etc. Operational performance, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0078] Examples:

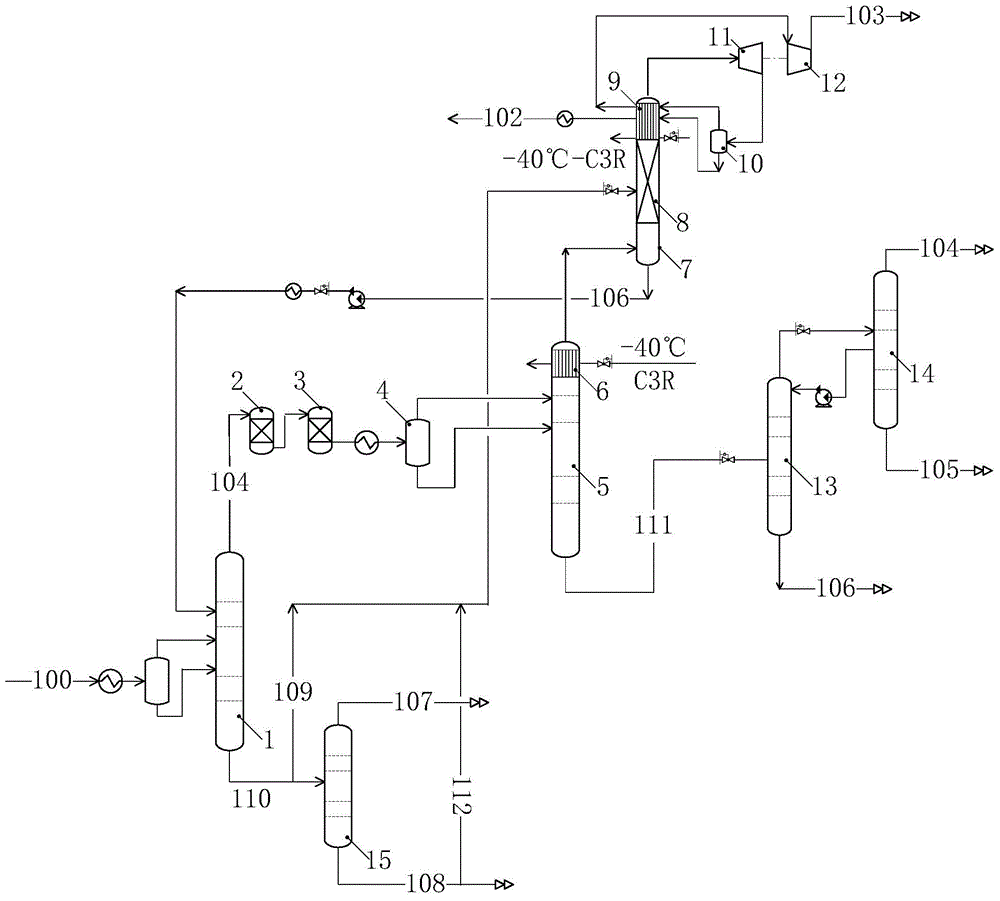

[0079] Such as figure 1 Shown is a system for recovering ethylene from high propylene light hydrocarbons or methanol to propylene product gas.

[0080] Including: first deethanizer 1, depropanizer 15, dryer 2, hydrogenation reactor 3, demethanizer 5, demethanizer tail gas recovery unit, second deethanizer 13, and ethylene rectification tower 14 ;

[0081] The tail gas recovery unit consists of a combined absorption tower 7, an expander 11 and a second gas-liquid separation tank 10. The upper part of the combined absorption tower 7 is a cryogenic rectification tower section 9, and the lower part is an absorption tower section 8.

[0082] The top of the first deethanizer 1 is connected to the dryer 2 and then to the hydrogenation reactor 3, the lower part of the hydrogenation reactor 3 is connected to a gas-liquid separation tank 4, and the gas-liquid separation tank 4 is connected to the demethanizer 5;

[0083] The bottom pipeline of the first deethanizer 1 is divid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap