A method for producing electrolytic nickel

An electrowinning and electrowinning cell technology, applied in the field of metallurgy, can solve the problems affecting the optimization of technical and economic indicators, low content, etc., and achieve the effects of improving chemical quality and physical appearance quality, optimizing process, and reducing chemical composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

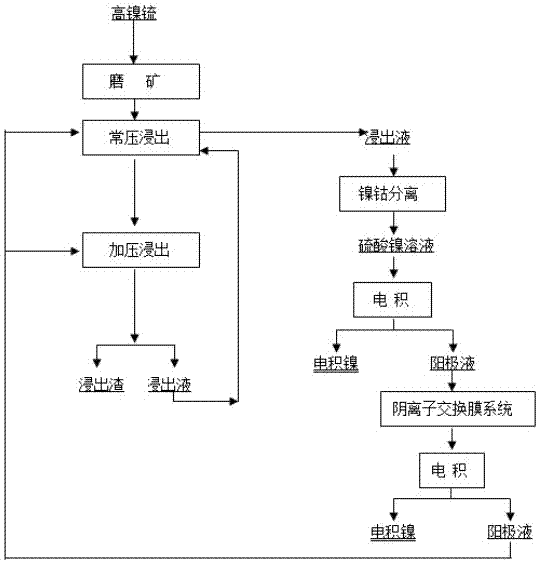

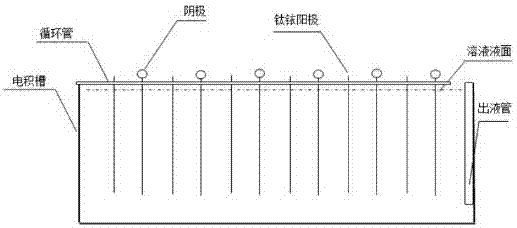

[0020] A method for electrolytic nickel deposition of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] Such as figure 1 , figure 2 As shown, the purpose of the present invention is to provide a Ni9996 electrolytic nickel production method, the anolyte generated in the electrolytic process is diffused and dialysis to make the pH reach 2.5-3.5, and enter the electrolytic cell as the electrolytic catholyte to produce high-quality electrolytic deposition. nickel. The cathode of the electrowinning cell is not covered with a diaphragm bag, and the anode is a titanium-based iridium-coated anode. After diffusion dialysis, the anolyte recovers a sulfuric acid concentration of 16-28g / L and returns to the front-end leaching process for batching. After industrial application, the chemical quality and physical appearance quality of electrodeposited nickel are improved, the process is optimized, and the production an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com