Construction method for pile-head-expanded bored pile

A technology of bored cast-in-place piles and construction methods, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low construction noise of bored cast-in-place piles, time-consuming and labor-intensive treatment of pile heads, and pile damage, etc. The effect of avoiding mud pollution, omitting the pile cutting process, and avoiding pile damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

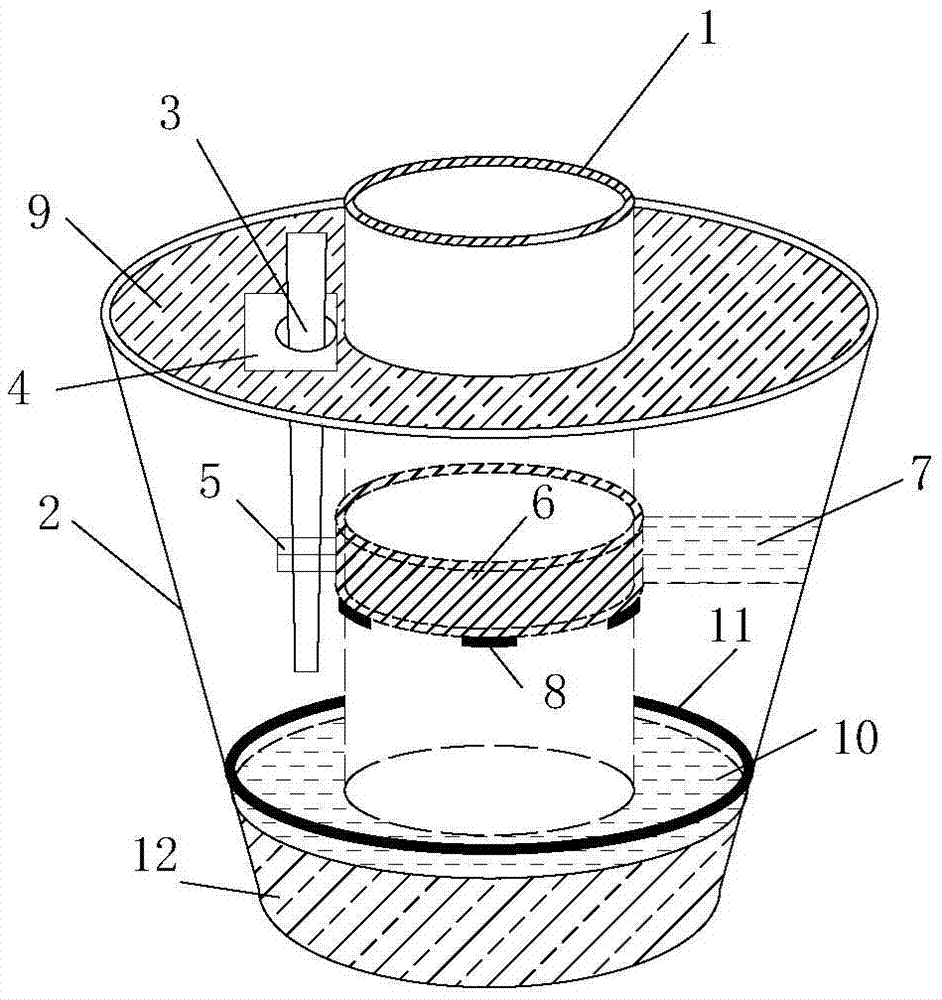

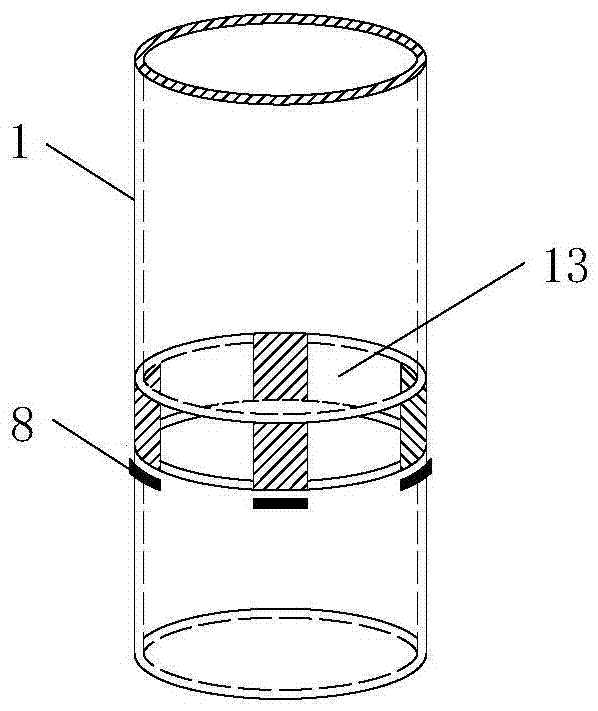

[0029] Such as figure 1 As shown, the double-layer steel casing construction device for the pile head enlarged bored pile is mainly composed of an inner steel pipe casing 1 and an outer steel pipe casing 2 . according to figure 2 As shown, the inner steel pipe casing 1 is cylindrical, with an inner diameter of 600 mm, and is made of a 12 mm thick, Q235 hot-rolled coil. Four overflow holes 13 symmetrically distributed along the circumference of the inner steel pipe casing 1 are provided with a hole height of 100 mm. There are four closed-loop limiting plates 8 correspondingly near the overflow holes for positioning the closed loop.

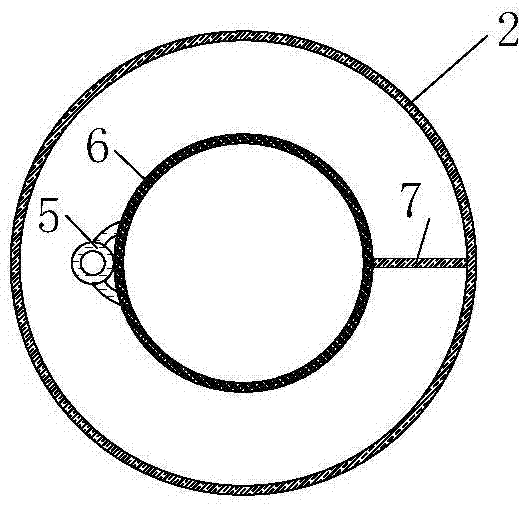

[0030] refer to figure 1 and image 3 As shown, the outer steel pipe casing 2 is conical in shape, and is formed by rolling and welding hot-rolled coils with a strength grade of Q235 and a thickness of 15 mm. The outer steel tube casing is mainly composed of top plate 9, bottom plate 10, closed ring 6, rib plate 7, positioning ring plate 11, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com