Light control pneumatic exhaust window

A technology for lighting control and smoke exhaust windows, which is applied in door/window accessories, power control mechanisms, buildings, etc., to achieve the effect of being suitable for large-scale industrial production and solving the problem of automatic opening and closing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] For further illustrating the present invention, now cooperate with accompanying drawing to elaborate:

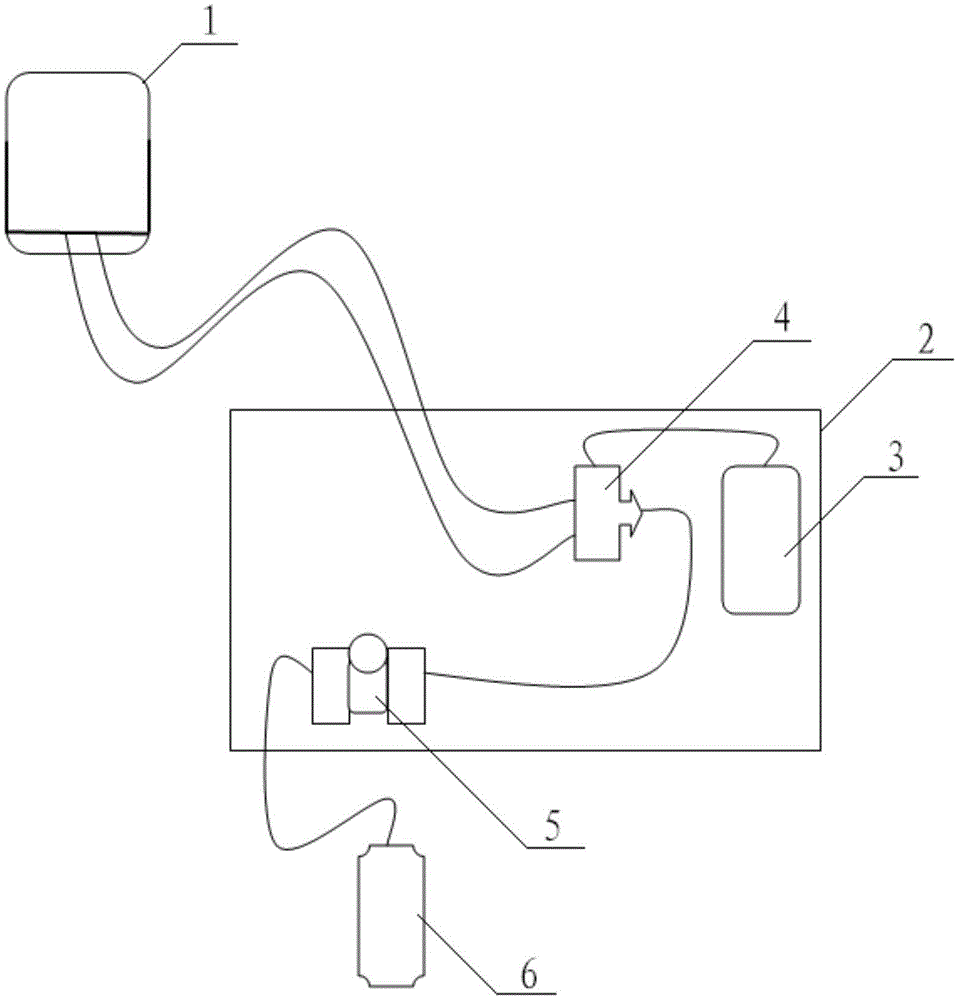

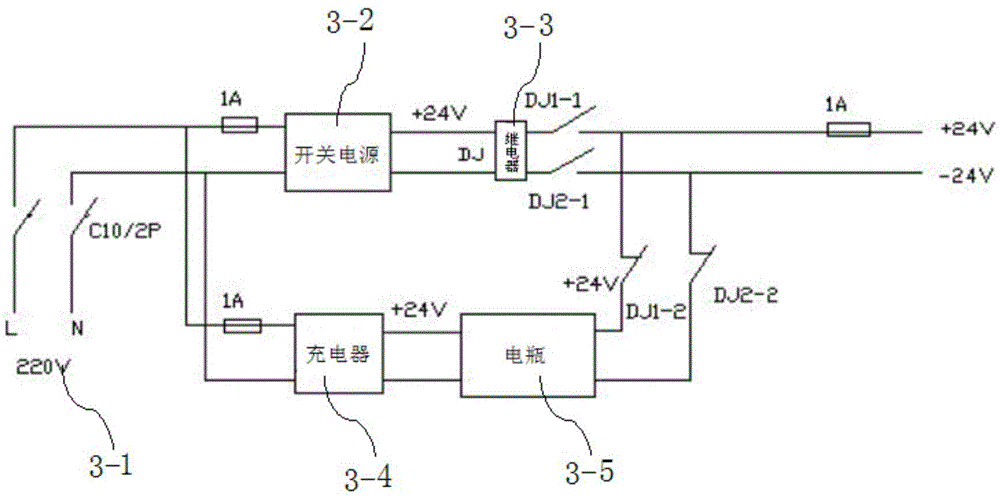

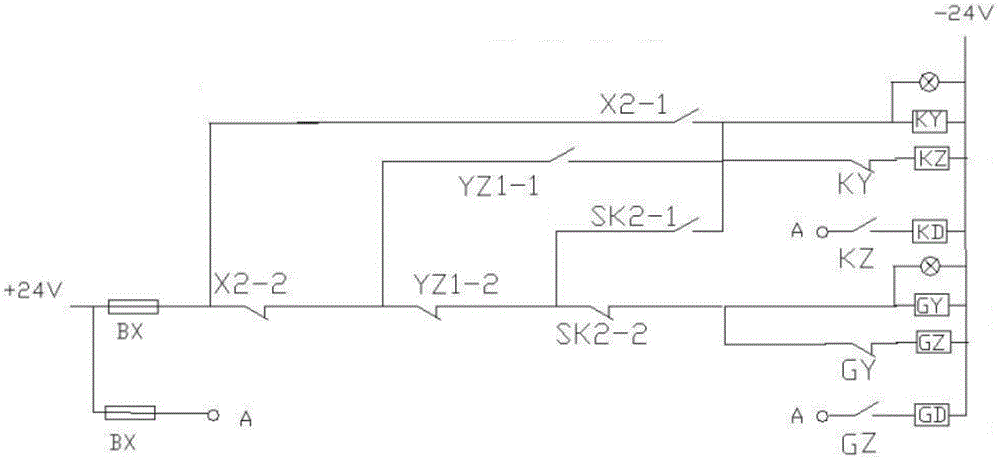

[0023] Such as Figure 1-4 As shown, the light control pneumatic smoke exhaust window includes a pneumatic smoke exhaust window 1, an air pump 6, a box body 2, a light induction control box 3 arranged in the box body 2, a pneumatic solenoid valve 4 and a gas-water separator 5. The pneumatic solenoid valve is a three-way structure, the outlet at one end is connected to the pipeline of the gas-water separator, and the outlet at the other two ends is connected to the pipeline of the sliding support part of the pneumatic smoke exhaust window (one of the ports pumps out gas using the sliding support part Push open the window, the other port sucks in gas and closes the window by sliding support parts), the air pump is connected with the gas-water separator pipeline, the light induction control box is connected with the pneumatic solenoid valve circuit, and at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com