A four-pipe layered water injection process string

A technique of string and layered water injection, which is applied in the direction of drill pipe, casing, wellbore/well components, etc., can solve the problems of packer unsealing, waste of manpower and material resources, and high maintenance cost, and achieve easy maintenance, The effect of stable work and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

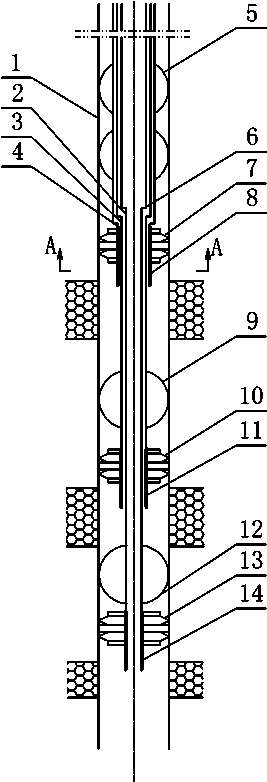

[0014] The four-tube layered water injection process string of the present invention will be further described in detail below in conjunction with the accompanying drawings.

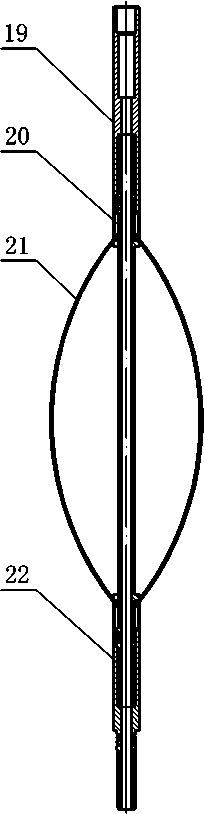

[0015] Such as figure 1 As shown, the four-tube layered water injection process string of the present invention includes casing 1 and wellhead, and the upper bridge plug 7, the middle bridge plug 10 and the lower bridge plug 13 are arranged at intervals in the casing pipe from top to bottom, and the upper bridge plug The plug, the middle bridge plug and the lower bridge plug divide the inside of the casing into four sections in the axial direction: upper, middle, lower and bottom. Each section corresponds to a water injection section. Layer tubing 2 constitutes.

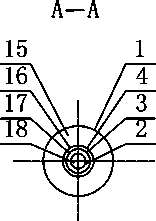

[0016] Such as figure 2 As shown, the outer oil pipe, the middle oil pipe and the inner oil pipe radially divide the inside of the casing into a set of outer annular water injection channel 15 , outer middle annular water injection channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com