Thermoelectric refrigerating unit and method for improving refrigerating efficiency of thermoelectric refrigerating unit

A technology of thermoelectric cooler and hot arm, which is applied to the operation mode of the machine, refrigerator, refrigeration components, etc., can solve the problems of inability to achieve the cooling efficiency of traditional refrigeration devices, small cooling temperature difference between the cold end and the hot end, and low thermoelectric conversion rate, etc. problem, to achieve the effect of improving the efficiency of thermoelectric conversion and increasing the temperature difference of refrigeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

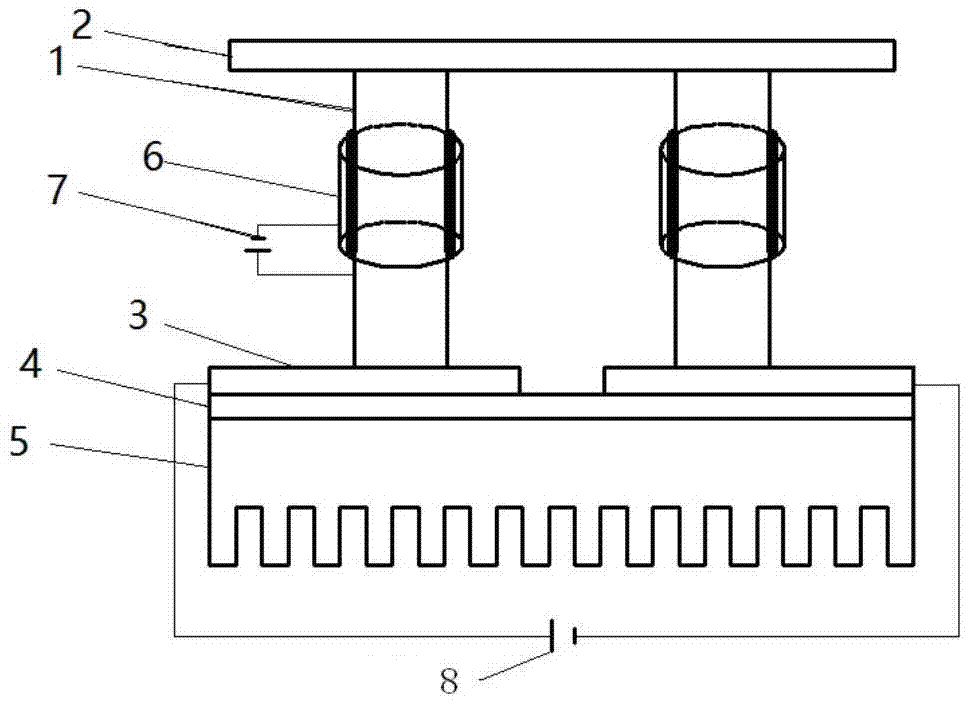

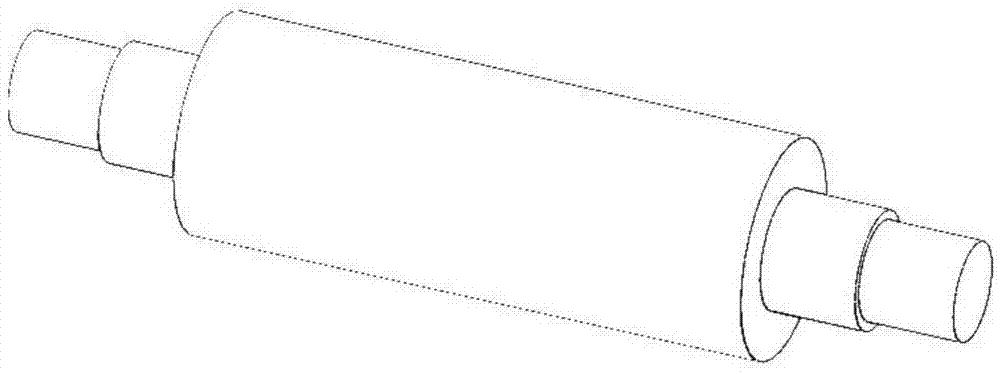

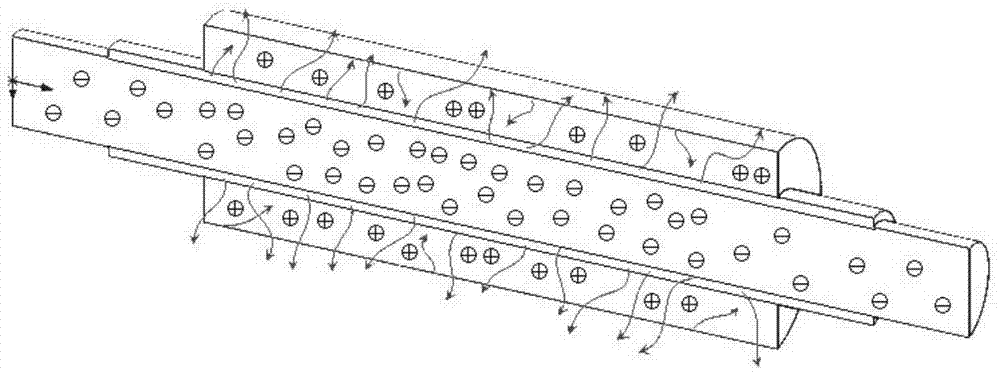

[0019] Reference attached figure 1 , showing the circuit structure of the thermoelectric refrigerator of the present invention, including a semiconductor thermal arm 1, the two ends of the semiconductor thermal arm are divided into a heat-absorbing end and a heat-dissipating end; the second DC power supply 8 provides a driving current, and the electrode 3 passes through the heat-releasing end Connection, semiconductor thermal arm 1 and heat-absorbing end electrode 2 form a loop, heat-absorbing end electrode 2 absorbs heat to become a heat-absorbing end, and exothermic end electrode 3 releases heat to form an exothermic end; heat sink 5 is connected to exothermic end electrode 3 Dissipate heat to the outside air; in order to achieve good electrical insulation and heat conduction, an insulating ceramic 4 is provided between the metal heat sink and the exothermic end electrode for isolation, and the exothermic end electrode and the insulating ceramic pass through silicone grease w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com