Water-saving fog dissipation cooling tower device and system based on micro heat pipe arrays

A technology of micro-heat pipes and cooling towers, which is applied in the field of water-saving and fog-eliminating cooling tower heat exchange equipment and systems, can solve problems such as unreasonable structure, large cooling water loss, and large pollution, so as to improve heat exchange performance and reduce treatment ratio , The effect of small thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

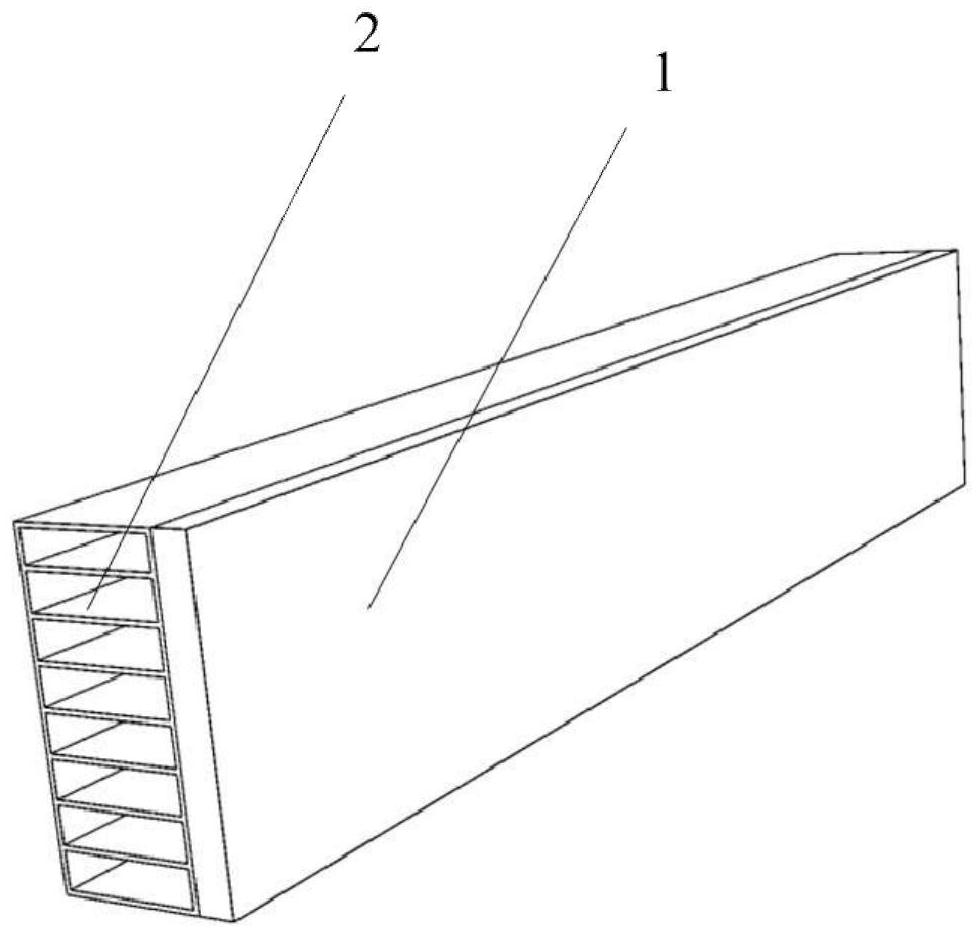

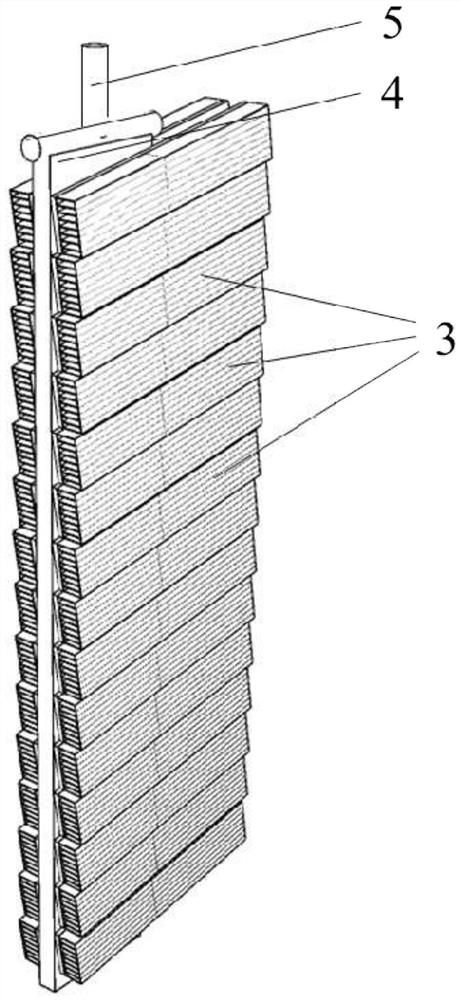

[0045] This embodiment is based on the vertical heat exchanger equipment and system of the dry section of the water-saving and fog-eliminating cooling tower based on the micro heat pipe array. The heat exchange unit of the vertical heat exchanger is as follows figure 1 As shown, the air-cooled finned air duct 2 is pasted on the outer wall of the micro heat pipe array 1. The thickness of the micro heat pipe array is 5mm and the width is 30mm. According to the application requirements, the thickness of the micro heat pipe array is 0.3-15mm and the width is 10mm. -120mm can also be adjusted. The single hole size of the finned air duct is above 5mm, which reduces the flow resistance on the air side and reduces the risk of blockage. The bonded parts are pasted and tightly compacted with thermally conductive silica gel with high thermal conductivity. According to the process requirements, they can also be directly welded together by brazing. The above-mentioned one micro heat pipe ...

Embodiment 2

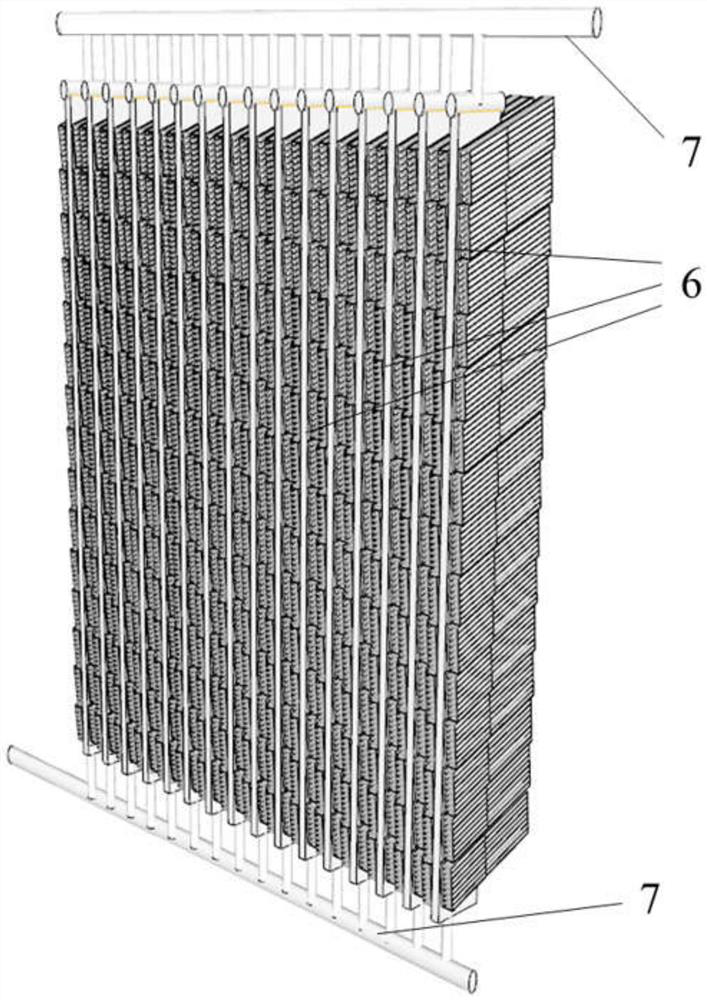

[0050] This embodiment is based on the horizontal heat exchanger equipment and system of the dry section of the water-saving and fog-eliminating cooling tower based on the micro heat pipe array. The heat exchange unit of the horizontal heat exchanger is as follows Figure 5 As shown, the air-cooled finned air ducts 2 are attached to the two side walls of the vertically placed micro heat pipe array 1. According to the use requirements, the thickness of the micro heat pipe array can be adjusted between 0.3-15mm and the width between 10mm-120mm. The single hole size of the finned air duct is above 5mm, which reduces the flow resistance on the air side and reduces the risk of blockage. The bonded parts are pasted and tightly compacted with thermally conductive silica gel with high thermal conductivity, and can also be directly welded together by brazing process according to process requirements. The heat exchange unit 13 is composed of one micro heat pipe array 1 and multiple air-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com