Flexible thermal electromagnetic energy conversion film with enhanced refrigeration performance and preparation method thereof

A refrigeration performance and energy conversion technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, etc., to achieve the effect of improving refrigeration capacity, simple and controllable preparation method, and improving performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

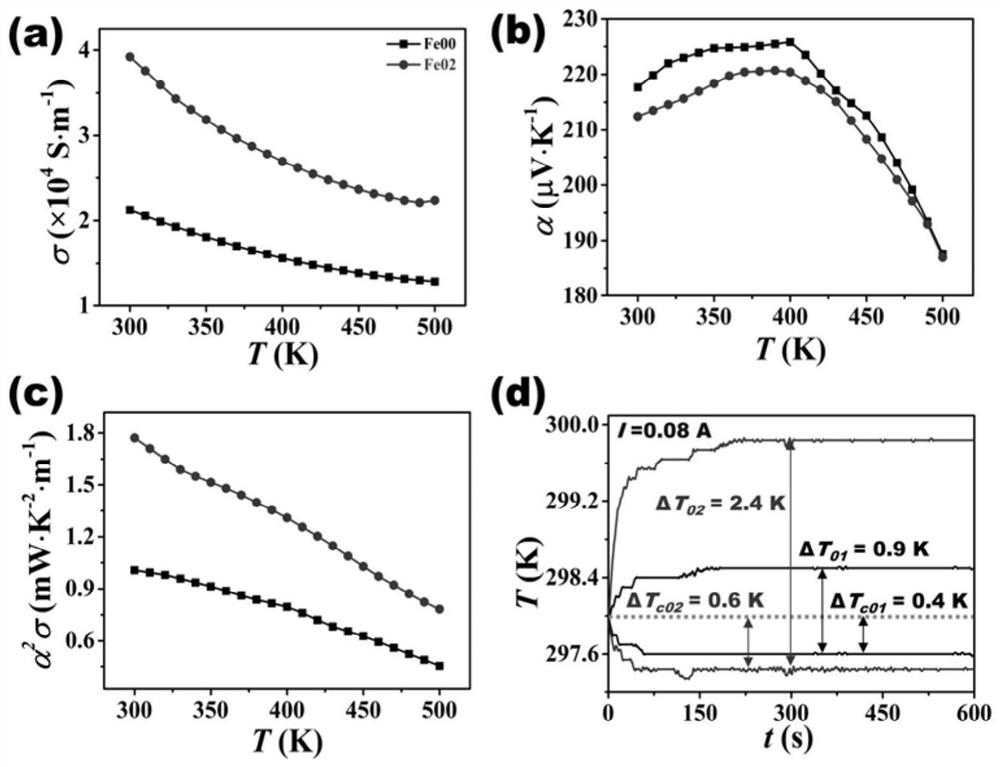

Embodiment 1

[0024] Preparation of Fe / Bi by Adding 0.2wt% Fe Magnetic Nanoparticles 0.5 Sb 1.5 Te 3 The process of thermo-electromagnetic energy conversion film is as follows:

[0025] p-type bismuth telluride (Bi 0.5 Sb 1.5 Te 3 , BST) ingots are crushed and sieved to obtain BST thermoelectric powders with a particle size of less than 120 μm. Accurately weigh 9.98g of BST powder and 0.02g of Fe magnetic nanoparticles, and add them together into a high-energy ball mill tank, then add 50g of absolute ethanol as the ball mill medium, and then pass in Ar gas for protection after vacuuming. The ball mill process parameters are: 200r / min, ball milling time 2h. After ball milling, the mixture was centrifuged and dried to obtain Fe / Bi 0.5 Sb 1.5 Te 3 Thermal electromagnetic composite powder.

[0026] Accurately weigh 0.612g bisphenol F diglycidyl ether epoxy resin, 0.521g methyl hexahydrophthalic anhydride, 0.123g 2-ethyl-4-methylimidazole, 1.8g butyl glycidyl ether, mix evenly to obtai...

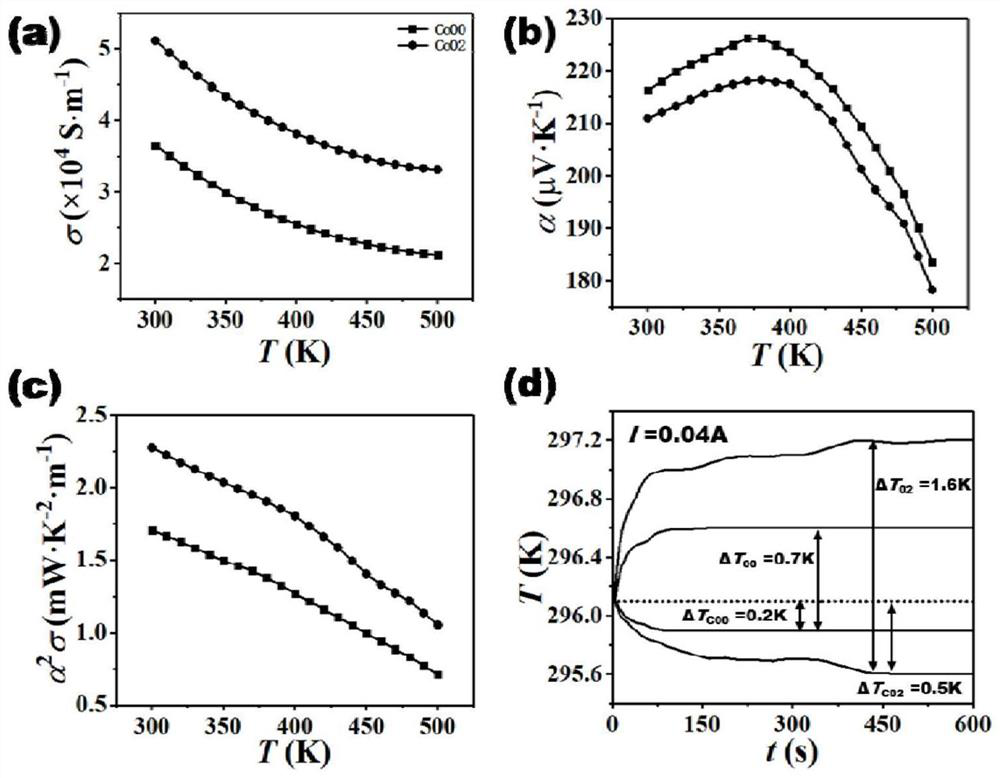

Embodiment 2

[0033] Preparation of Co / Bi by Adding 0.2wt% Co Magnetic Nanoparticles 0.5 Sb 1.5 Te 3 The process of thermo-electromagnetic energy conversion film is as follows:

[0034] p-type bismuth telluride (Bi 0.5 Sb 1.5 Te 3 , BST) ingots are crushed and sieved to obtain BST thermoelectric powders with a particle size of less than 120 μm. Accurately weigh 9.98g of BST powder and 0.02g of Co magnetic nanoparticles, and add them together into the high-energy ball mill tank, then add 50g of absolute ethanol as the ball mill medium, and then pass in Ar gas for protection after vacuuming. The ball mill process parameters are: 200r / min, ball milling time 2h. After ball milling, the mixture was centrifuged and dried to obtain Co / Bi 0.5 Sb 1.5 Te 3 Thermal electromagnetic composite powder.

[0035] Accurately weigh 0.2g bisphenol F diglycidyl ether epoxy resin, 0.17g methyl hexahydrophthalic anhydride, 0.04g 2-ethyl-4-methylimidazole, 0.9g butyl glycidyl ether, mix evenly to obtain ...

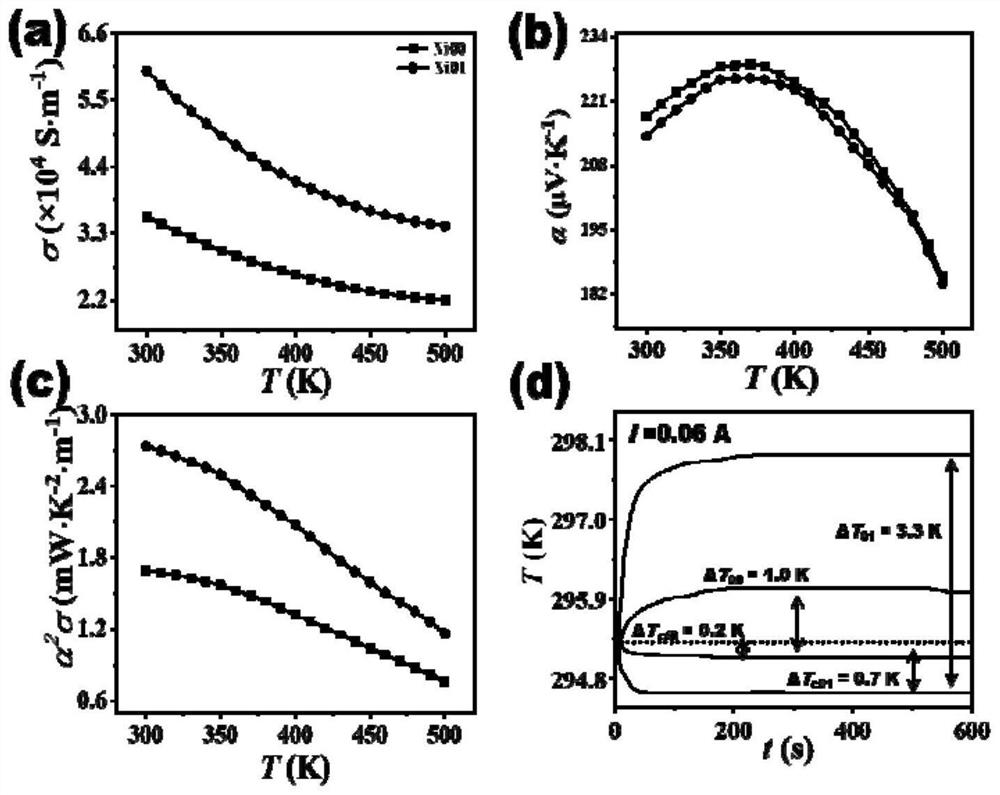

Embodiment 3

[0042] Preparation of Ni / Bi by Adding 0.1wt% Ni Magnetic Nanoparticles 0.5 Sb 1.5 Te 3 The process of thermomagnetic thin film is as follows:

[0043] p-type bismuth telluride (Bi 0.5 Sb 1.5 Te 3 , BST) ingots are crushed and sieved to obtain BST thermoelectric powders with a particle size of less than 120 μm. Accurately weigh 9.98g of BST powder and 0.01g of Ni magnetic nanoparticles, and add them together to the high-energy ball mill tank, then add 50g of absolute ethanol as the ball mill medium, and then pass in Ar gas for protection after vacuuming. The ball mill process parameters are: 200r / min, ball milling time 2h. After ball milling, the mixture was centrifuged and dried to obtain Ni / Bi 0.5 Sb 1.5 Te 3 Thermal electromagnetic composite powder.

[0044] Accurately weigh 0.2g bisphenol F diglycidyl ether epoxy resin, 0.17g methyl hexahydrophthalic anhydride, 0.04g 2-ethyl-4-methylimidazole, 0.9g butyl glycidyl ether, mix evenly to obtain epoxy resin binder sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com