Refrigeration cycle device

A refrigeration cycle and cavity control technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of small applicable working conditions, low performance, and inability to effectively improve the energy efficiency of the heating system, and achieve high operating efficiency, The effect of improving heating capacity and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

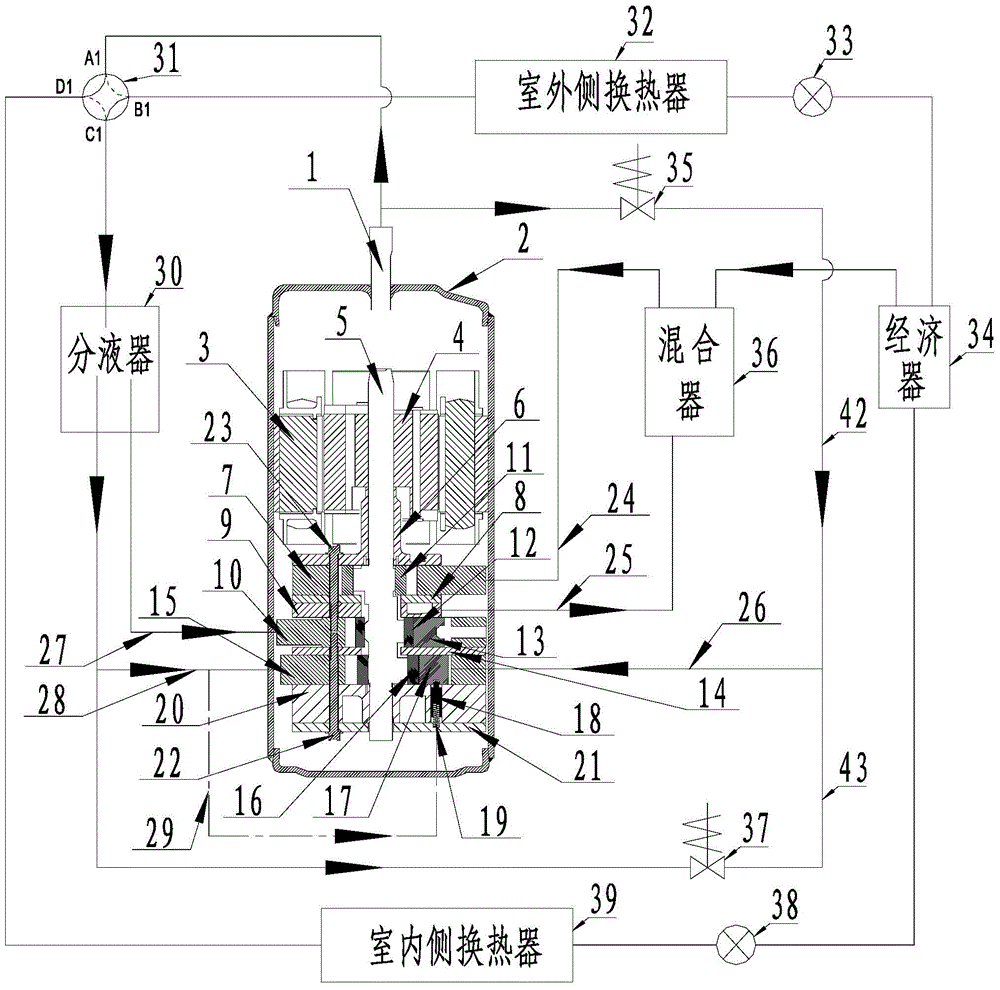

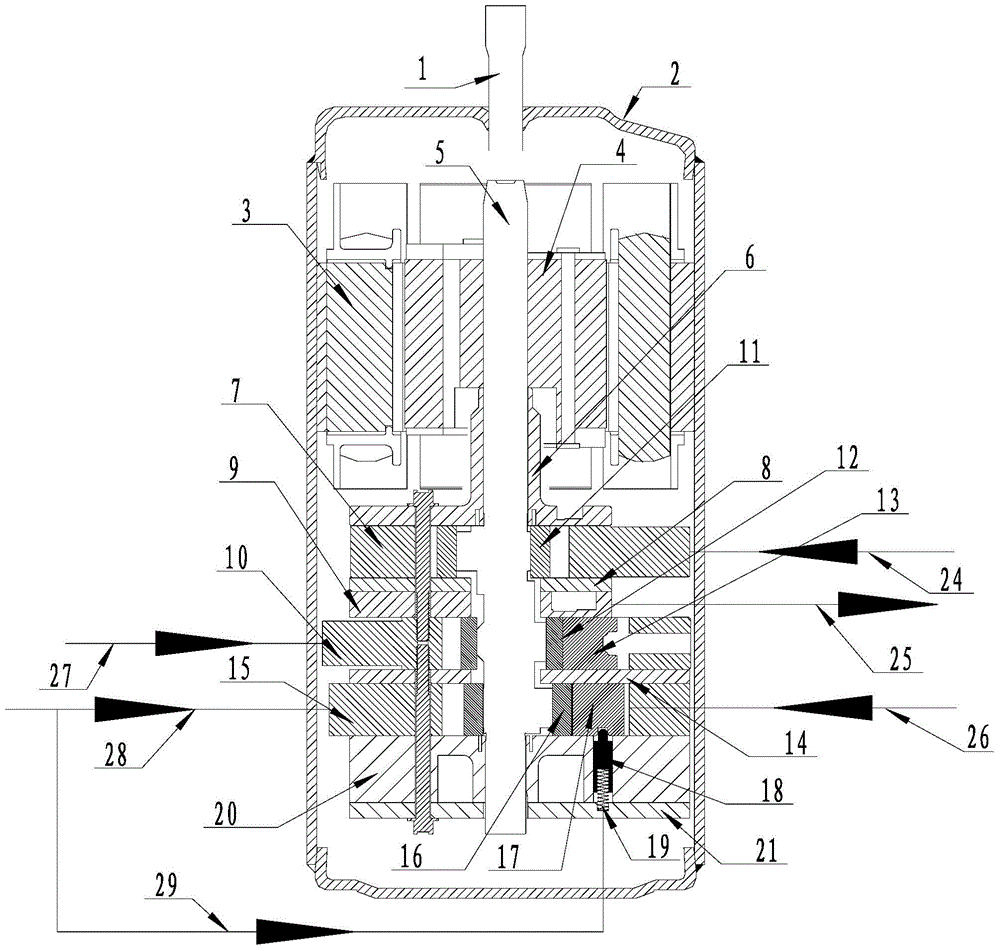

[0025] refer to Figure 1 to Figure 3 , taking a rotary compressor with one high-pressure cylinder and two low-pressure cylinders as an example to illustrate the inventive refrigeration cycle device, the compressor includes a high-pressure exhaust pipe 1, a sealed casing 2, a motor stator 3, a motor rotor 4, Crankshaft 5, upper flange 6, high-pressure cylinder 7, upper partition 8, middle partition 9, second low-pressure cylinder 10, high-pressure cylinder roller 11, second low-pressure cylinder roller 12, second low-pressure cylinder slide 13, Lower partition 14, first low-pressure cylinder 15, first low-pressure cylinder roller 16, first low-pressure cylinder slide 17, pin 18, spring 19, lower flange 20, lower flange cover 21, first screw 22, The second screw 23 .

[0026] Wherein, the first suction pipe 28 is used as the suction pipe of the first low-pressure cylinder 15, the second suction pipe 27 is used as the suction pipe of the second low-pressure cylinder 10, and the...

Embodiment 2

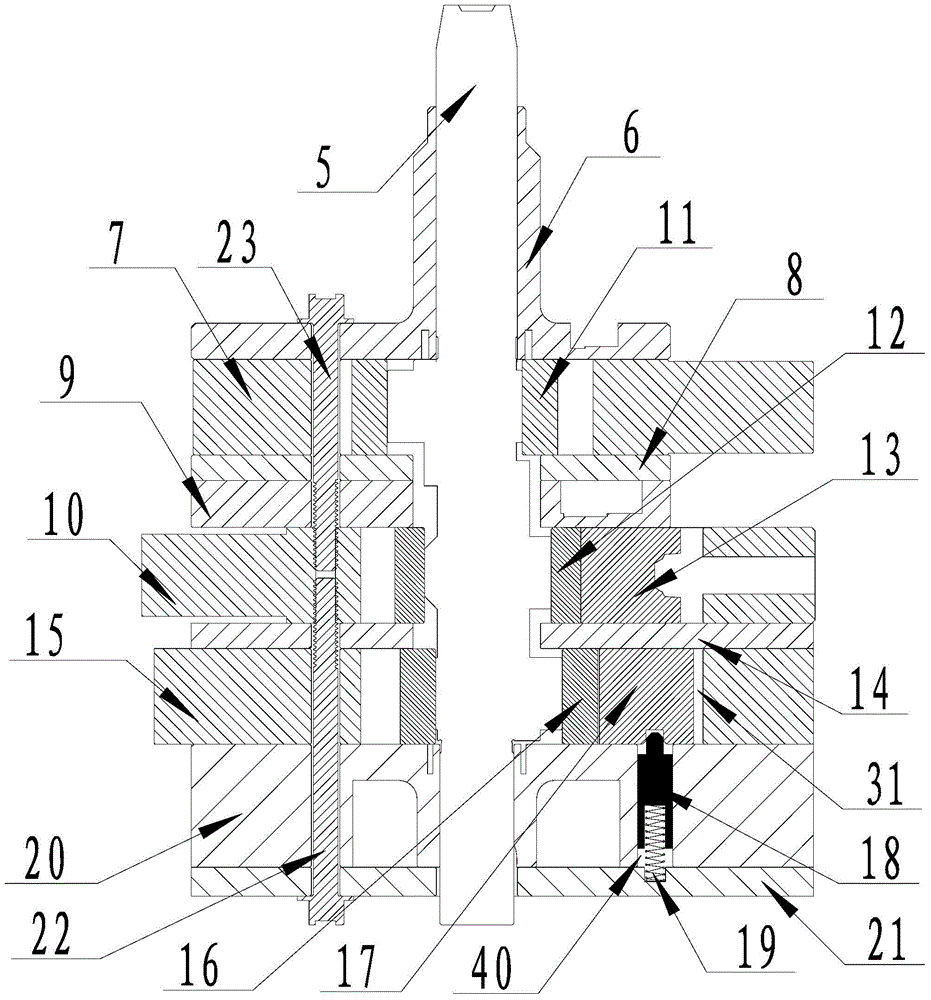

[0036] The main difference between Embodiment 2 and Embodiment 1 is that a three-way valve is used instead of the first electronic valve and the second electronic valve in Embodiment 1, and the first valve port of the three-way valve is connected to the high-pressure exhaust pipe of the rotary compressor. , the second valve port of the three-way valve is connected to the control chamber, and the third valve port of the three-way valve is connected to the low-pressure side of the refrigeration cycle device.

[0037] see Figure 2 to Figure 4 The first valve port A2 of the three-way valve 41 is connected to the high-pressure exhaust pipe 1, the second valve port B2 of the three-way valve 41 is connected to the intake pipe 26, and the third valve port C2 of the three-way valve 41 is connected to the refrigeration cycle device. On the low-pressure side, the third valve port C2 of the three-way valve 41 in the figure communicates with the liquid separator 30 . The communication be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com