Active absorption type plate-pushing wave generation device and method based on moment feedback

An absorption-type, push-plate technology, which is applied in measuring devices, fluid dynamics tests, and machine/structural component tests, can solve the problems of low measurement accuracy of water level sensors, susceptibility to environmental influences, and unsatisfactory elimination of reflected waves. Achieve the effect of convenient acquisition, small environmental impact and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0014] The invention will be described in detail below with reference to the accompanying drawings and examples.

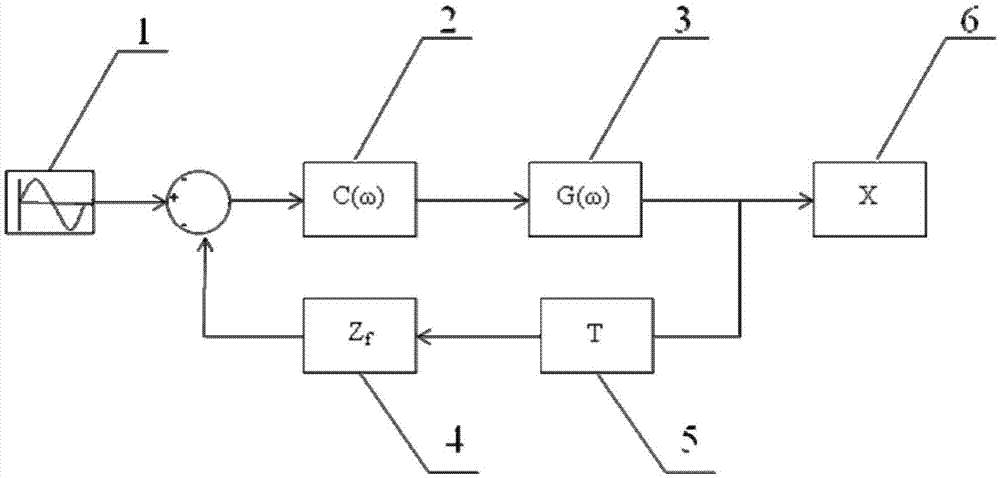

[0015] The principle of active absorbing wave-making based on torque feedback provided by the invention is that the existence of reflected waves will affect the force on the push plate, thereby affecting the torque of the servo motor; The output torque is compared with the theoretical torque under the condition of no reflection through the absorption filter, and the motion signal is corrected by real-time feedback to achieve the purpose of active absorption wave generation.

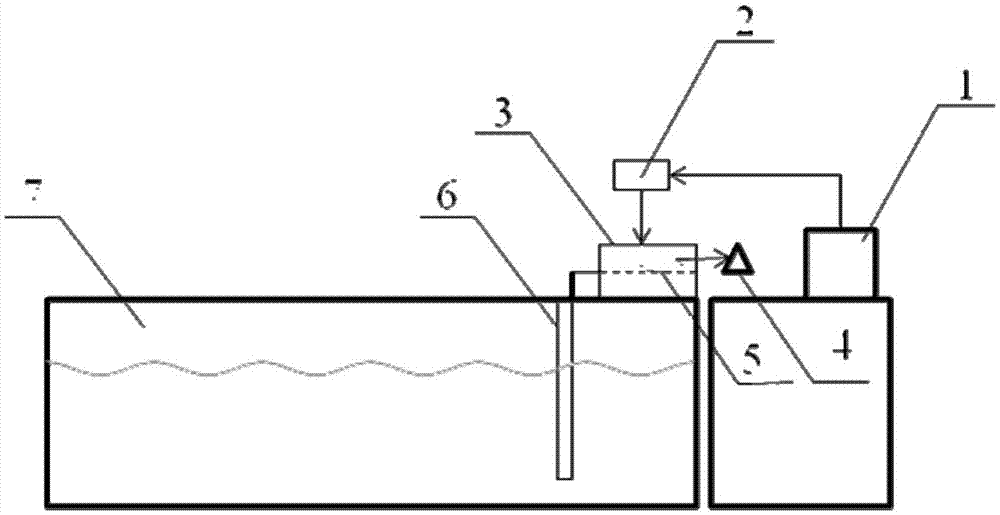

[0016] Based on the above principles, the present invention provides an active absorbing push plate wave-making device based on torque feedback, including an industrial computer 1, a controller 2, a servo motor 3, a torque ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com