A Fault Detection Method for Power Equipment Based on Isotherm Drawing

A power equipment and fault detection technology, which is applied in the field of power equipment fault detection based on isotherm drawing, can solve the problem of not being able to automatically, quickly and intuitively obtain the fault location of power equipment, and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

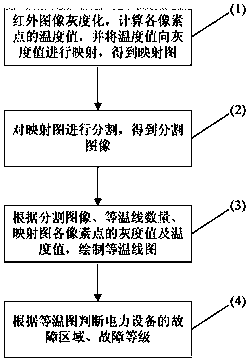

[0032] Such as figure 1 Shown, the present invention realizes according to the following steps:

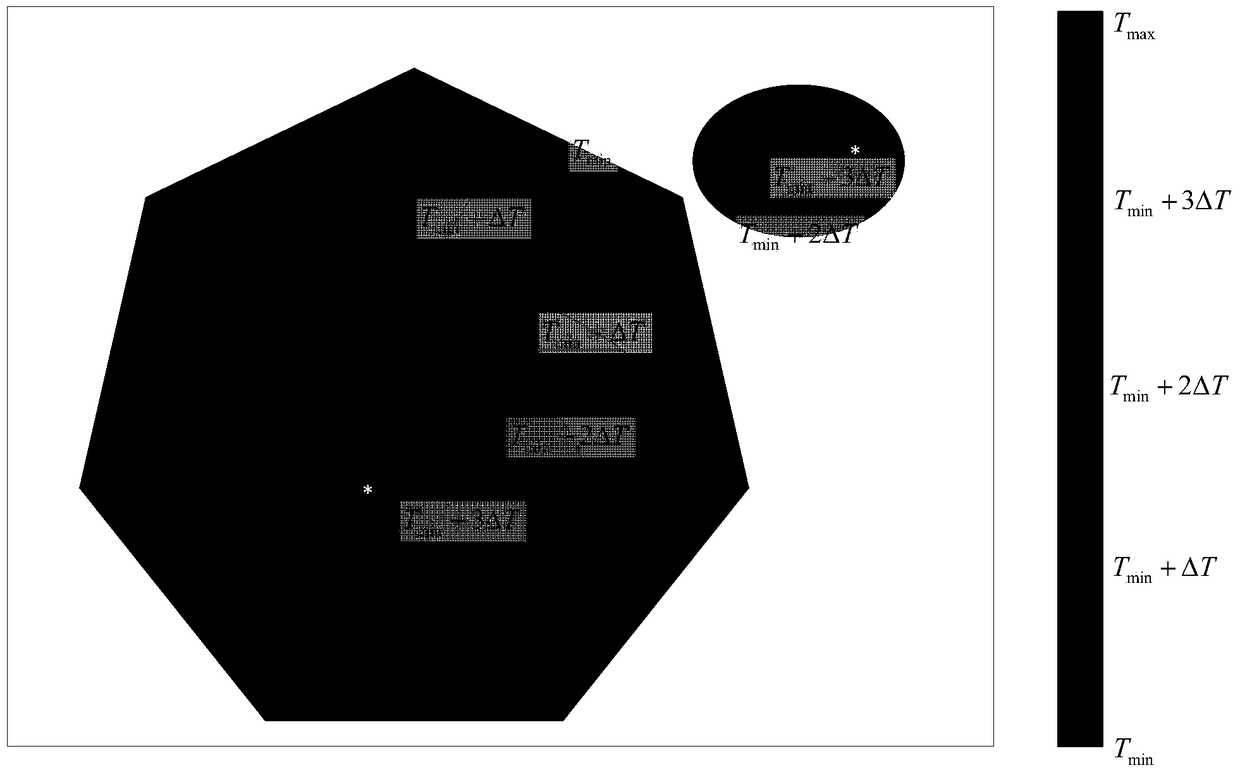

[0033] (1) Obtain the infrared image of the power equipment, convert the infrared image to grayscale, and obtain the grayscale image, combined with comprehensive consideration of the emissivity of the object, the reflected apparent temperature, the distance between the object and the thermal imager, and the relative The temperature field model after humidity, atmospheric temperature and other factors, calculate the temperature of each pixel point, and determine the maximum temperature T max with minimum temperature T min , according to the mapping rule Map the temperature value t of each pixel point of the grayscale image to the grayscale value gray, and the image after the grayscale value is updated is the mapping image;

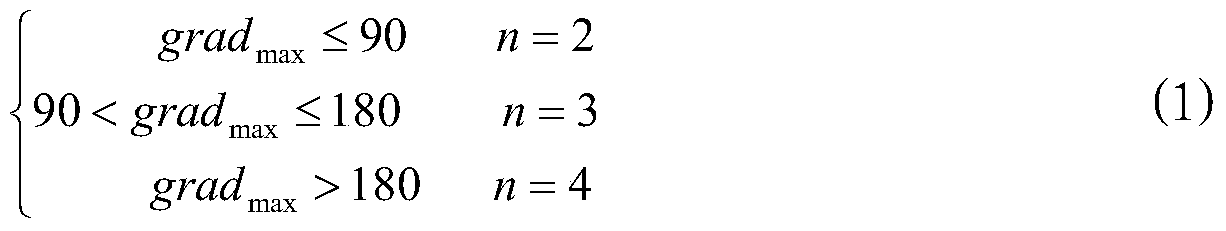

[0034] (2), determine the classification number n and the initial center of the clustering segmentation of the map, and divide the map according to the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com