A Constant Flow Control System and Belt Scale Fault Location Method

A fault location and control system technology, applied in the field of shredded tobacco processing, can solve problems such as long troubleshooting process, untraceable data, and inability to quickly locate faults, and achieve the effect of reducing process quality risks and troubleshooting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

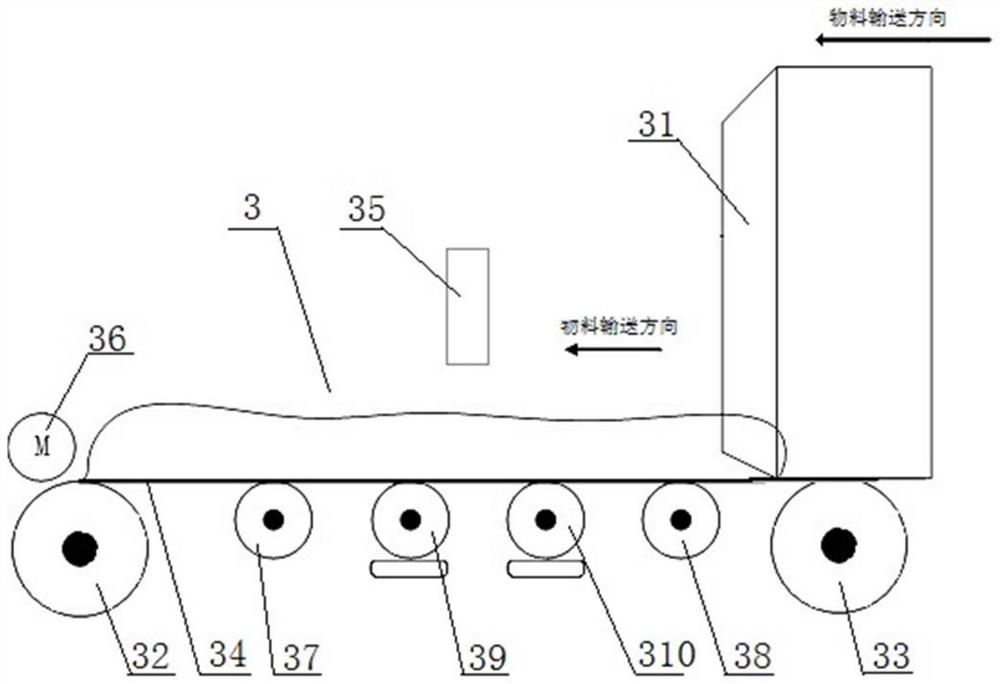

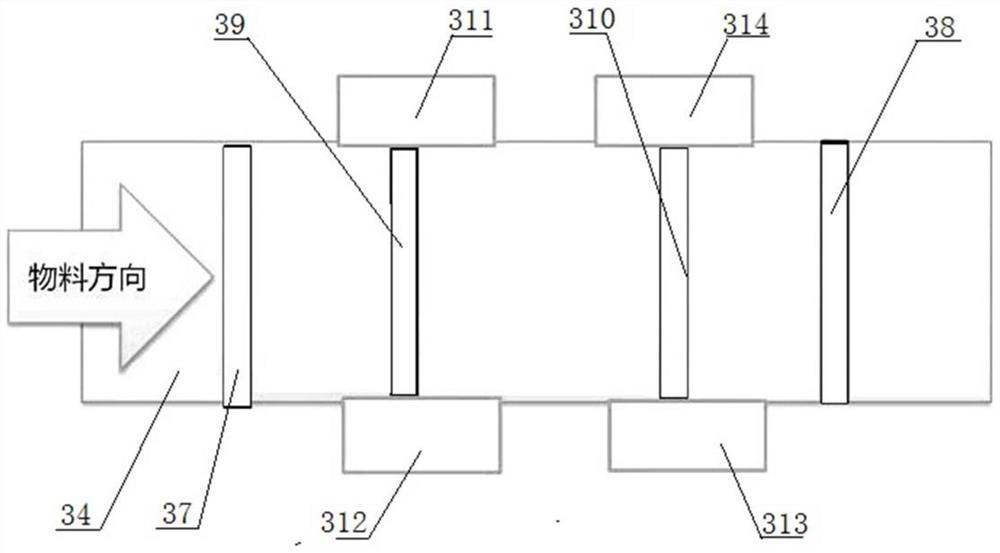

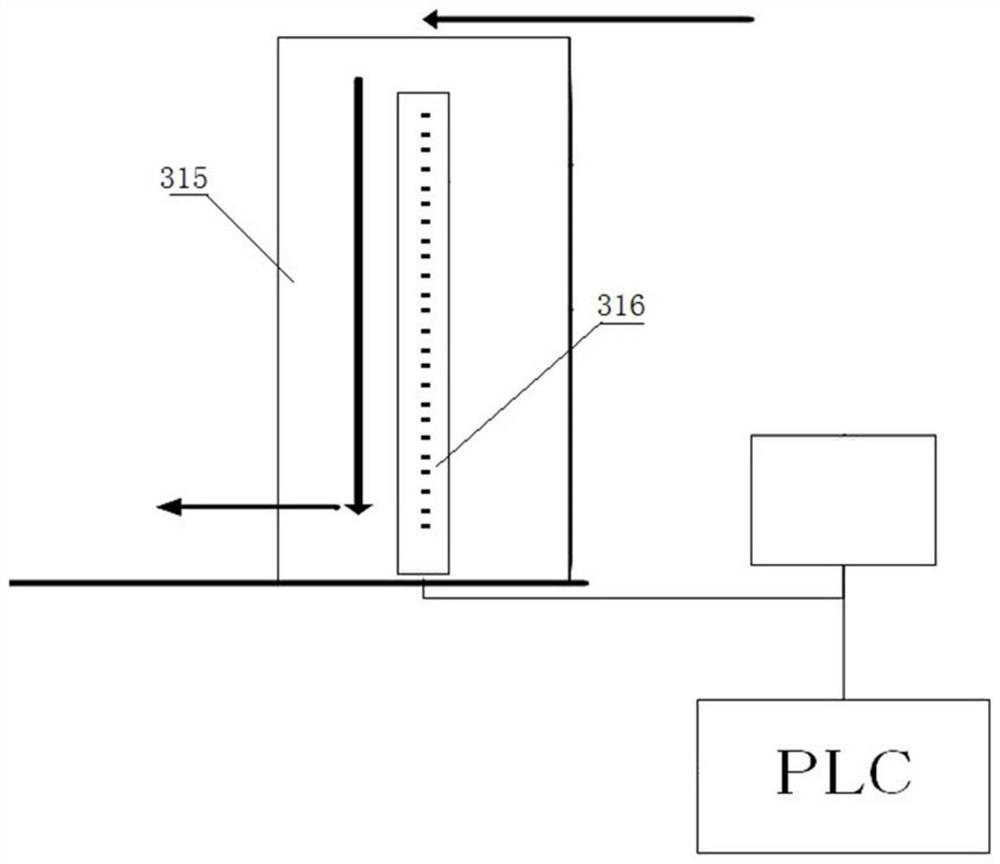

[0038] This embodiment is an embodiment of a constant flow control system, including a feeder containing a material distributing device 1, a temporary storage cabinet 2, and an electronic belt scale system 3. The temporary storage cabinet 2 is located below the material distributing device 1, and the electronic belt 34 weighs the system. There is a limited pipe 31 that receives cut tobacco from the temporary storage cabinet 2 . Such as figure 1 As shown, the electronic belt scale system 3 includes a controller, idler rollers, a driving roller 32, and a driven roller 33, and a belt 34 surrounds the idler rollers, the driving roller 32, and the driven roller 33, and the idler rollers are located between the driving roller 32 and the driven roller. Between 33, the limiting tube 31 is located above the end of the belt 34: a laser rangefinder 35 for measuring the height of the material is provided above the belt 34; the driving roller 32 is connected with a drive motor 36, and the ...

Embodiment 2

[0047] This embodiment is an embodiment of a belt scale fault location method, including the following steps:

[0048] S10. set up the material model delivered to the belt scale by the limiting pipe 31, and calculate the belt scale flow Q by the following formula:

[0049]

[0050] In the formula, L, H, and D represent the length, height and width of the material above the belt scale respectively, H is measured by the laser rangefinder 35, ρ is the material density, and S represents the speed of the belt scale measured by the rotary encoder; , H is inversely proportional to S;

[0051] S20. Calculate the real-time belt scale flow rate Q1 from the material weight G measured by the load cell according to the following formula:

[0052]

[0053] S30. Calculate the deviation rate P of Q and Q1 according to the following formula, and P is [-0.5%, 0.5%]:

[0054] P=[(Q-Q1) / Q]*100%

[0055] S40. When P is greater than 0.5% or less than -0.5%, output an early warning to check...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com