Fault diagnosis method and device for blower

A fault diagnosis, blower technology, applied in the direction of instruments, test/monitoring control systems, control/regulation systems, etc., can solve problems such as the amount of noise data that interferes with the operation of the blower, the inaccurate diagnosis of the blower system, and the large amount of collected information and data, etc. Improve the effect of data false positives, improve fault diagnosis rate, and reduce calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

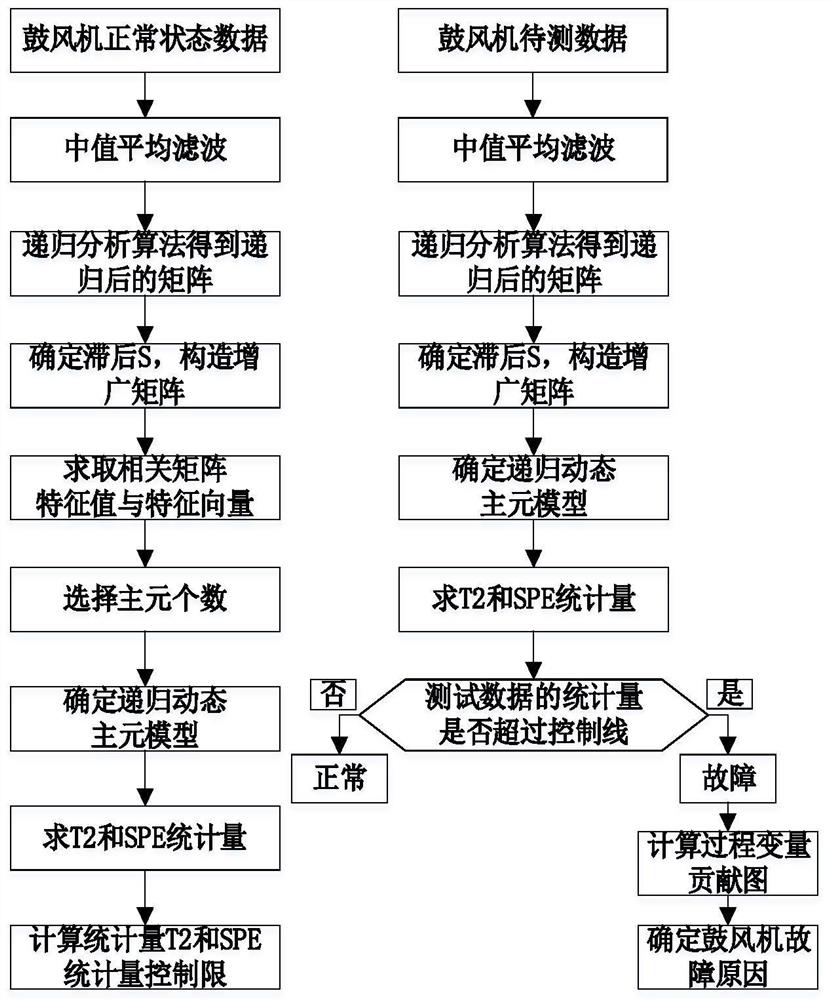

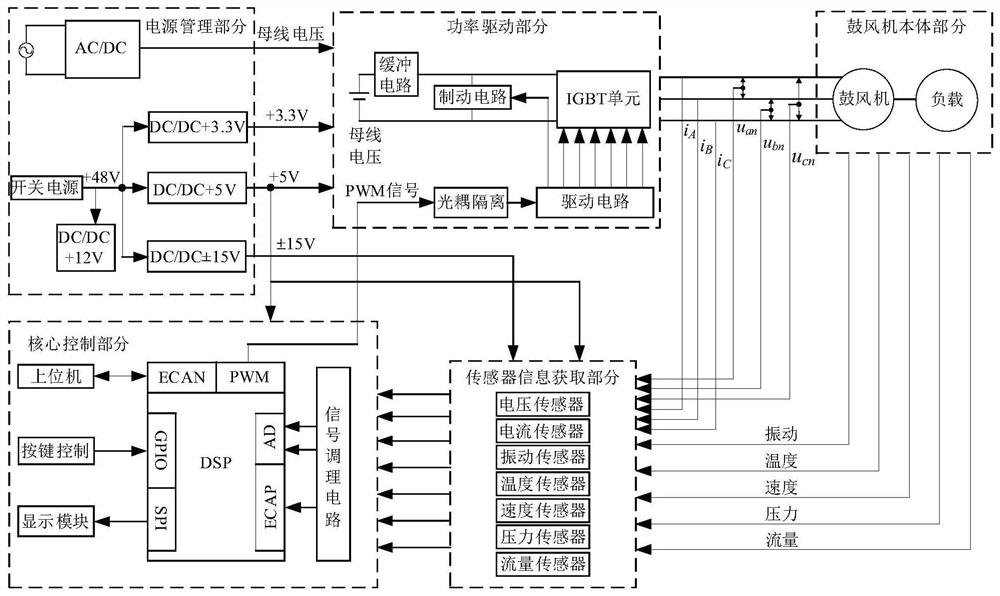

[0089] (1) if figure 1 As shown, in the blower operation process, the present invention utilizes the sensor to obtain the blower operation data in real time, first gathers 7 sensors of the blower under the normal operation situation, namely the current data of the current sensor collecting the blower motor, and the voltage sensor collecting the voltage of the blower motor Data, the vibration sensor collects the vibration data of the blower shell, the temperature sensor measures the temperature data of the blower motor part, the speed sensor measures the speed data of the blower motor, the pressure sensor measures the blower gas pressure data, and the flow sensor measures the blower gas flow rate data; the selected data length is M The different sensor data of the blower under normal conditions and form a matrix X. Select a data length k that is much ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com