Dual-computer redundant embedded control system suitable for nuclear industrial robot

An embedded control, dual-machine redundancy technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as difficulty in retrieving robots, and achieve the effect of good resource allocation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

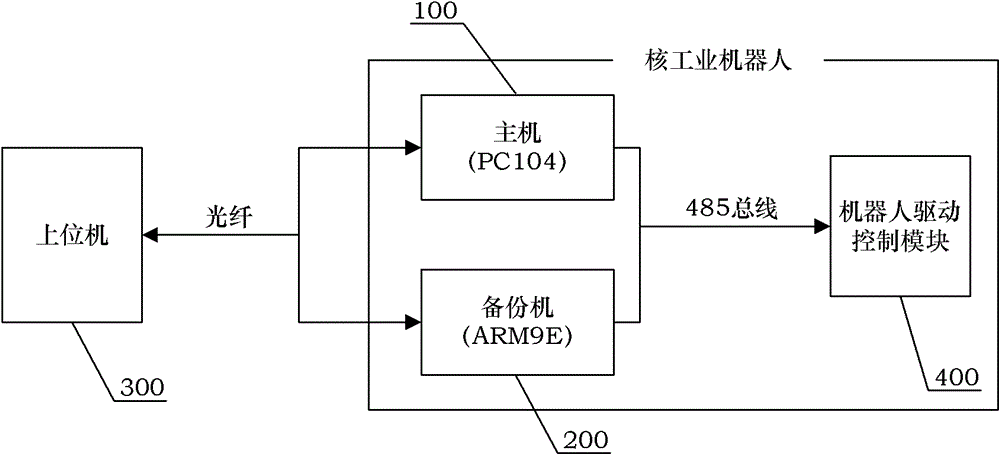

[0018] see figure 1 As shown, a kind of dual-machine redundant embedded control system (hereinafter referred to as dual-machine redundant control system) applicable to nuclear industry robot control of the present invention, this dual-machine redundant control system includes PC 104 as the main control The main machine 100 of the machine and the backup machine 200 with ARM9E as the controller, the main machine 100 and the backup machine 200 are installed on the nuclear industrial robot, and realize the electrical signal connection with the robot drive control module 400 through the 485 bus; Machine 300 realizes instruction information transmission.

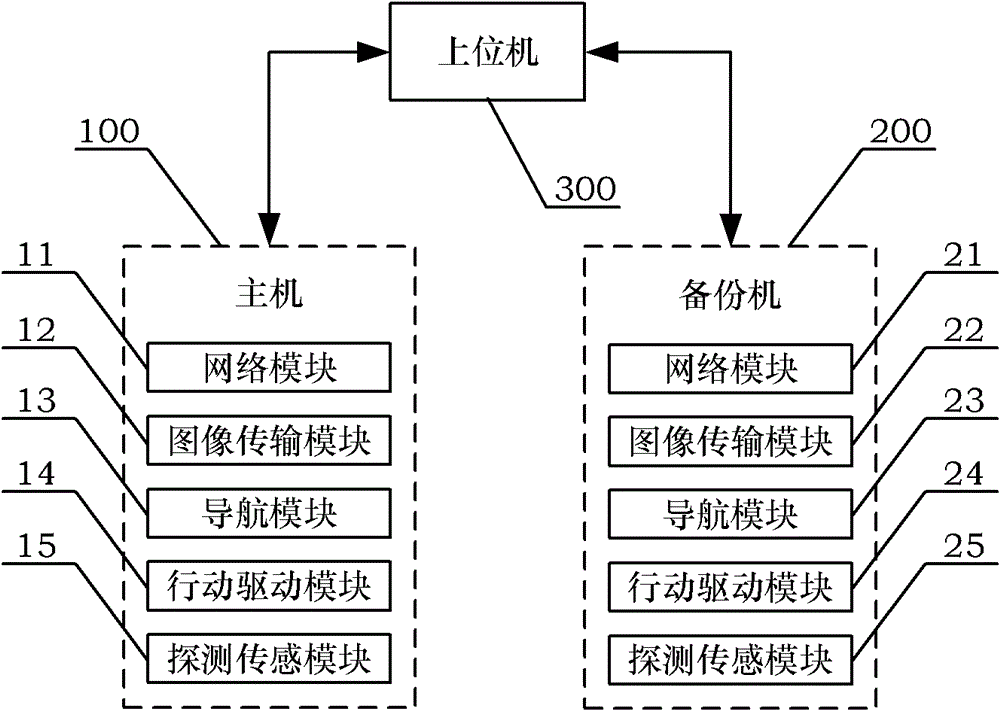

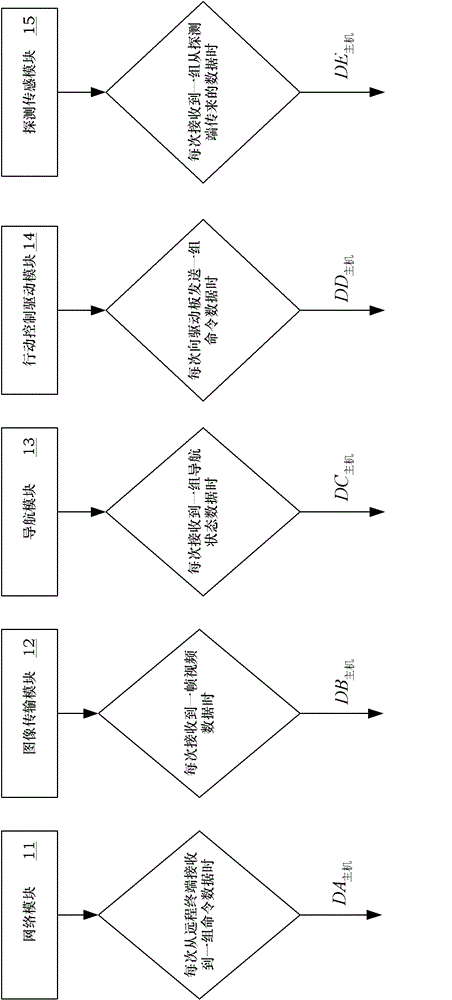

[0019] see figure 2 As shown, the host 100 is divided into a network module 11 , an image transmission module 12 , a navigation module 13 , an action driving module 14 and a detection and sensing module 15 acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com