Vacuumizing device and operation method using vacuumizing device

A technology for vacuuming devices and operating methods, which is applied to valve devices, sliding valves, instruments, etc., can solve the problems of vacuum chambers that cannot guarantee the sealing, and achieve the effect of ensuring the efficiency of pumping or inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions, and advantages to be solved by the embodiments of the present invention clearer, a detailed description will be given below with reference to the drawings and specific embodiments.

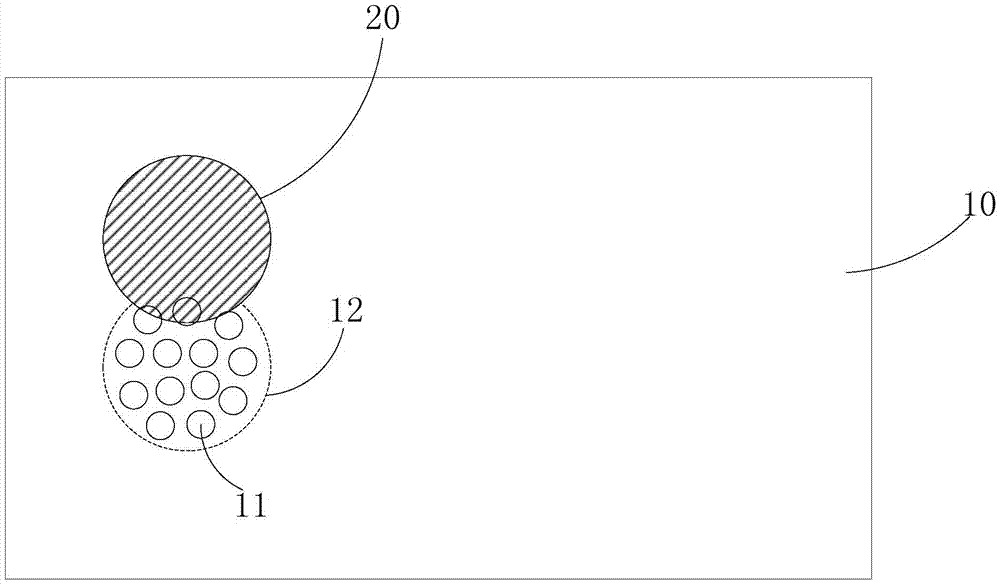

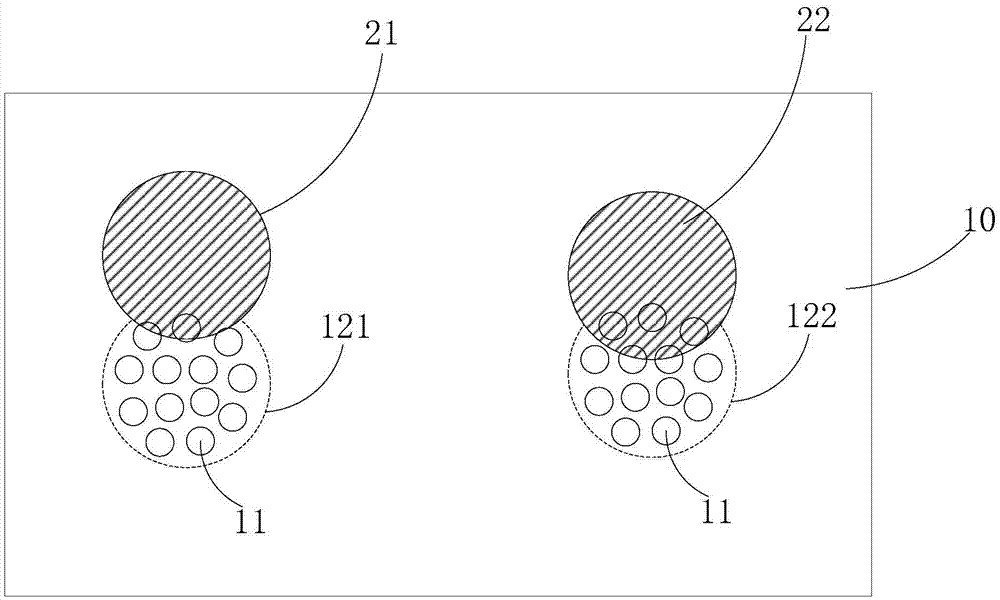

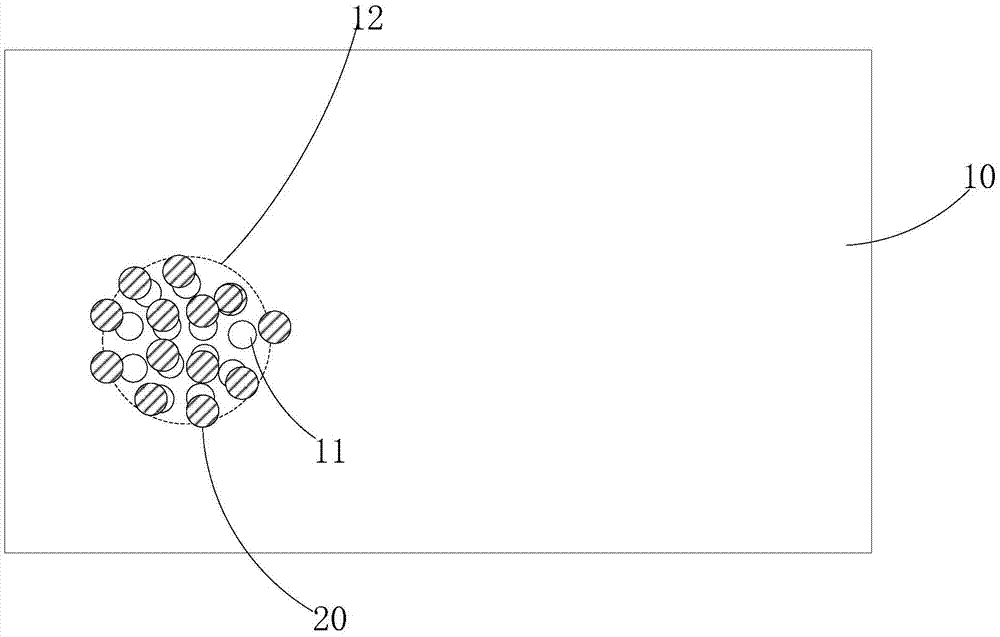

[0033] The vacuum device according to the embodiment of the present invention includes a cavity surrounded by an outer shell, wherein the outer shell includes: a through hole arrangement area, and a plurality of through hole arrangement areas are provided with a plurality of through holes. Hole; a sealing cover that is connected to the outer shell and can move between the first state and the second state;

[0034] Wherein, in the first state, the sealing cover is disposed on the through hole, and the cavity is sealed; in the second state, the sealing cover is moved away from at least part of the through hole , The through hole exposed through the sealing cover is formed as a gas circulation channel of the cavity.

[0035] Compared with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com