Feature-based machine tool accuracy optimization design method

A technology for optimizing design and machine tools, applied in computer control, instruments, simulators, etc., which can solve the problems of long cycle and large workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

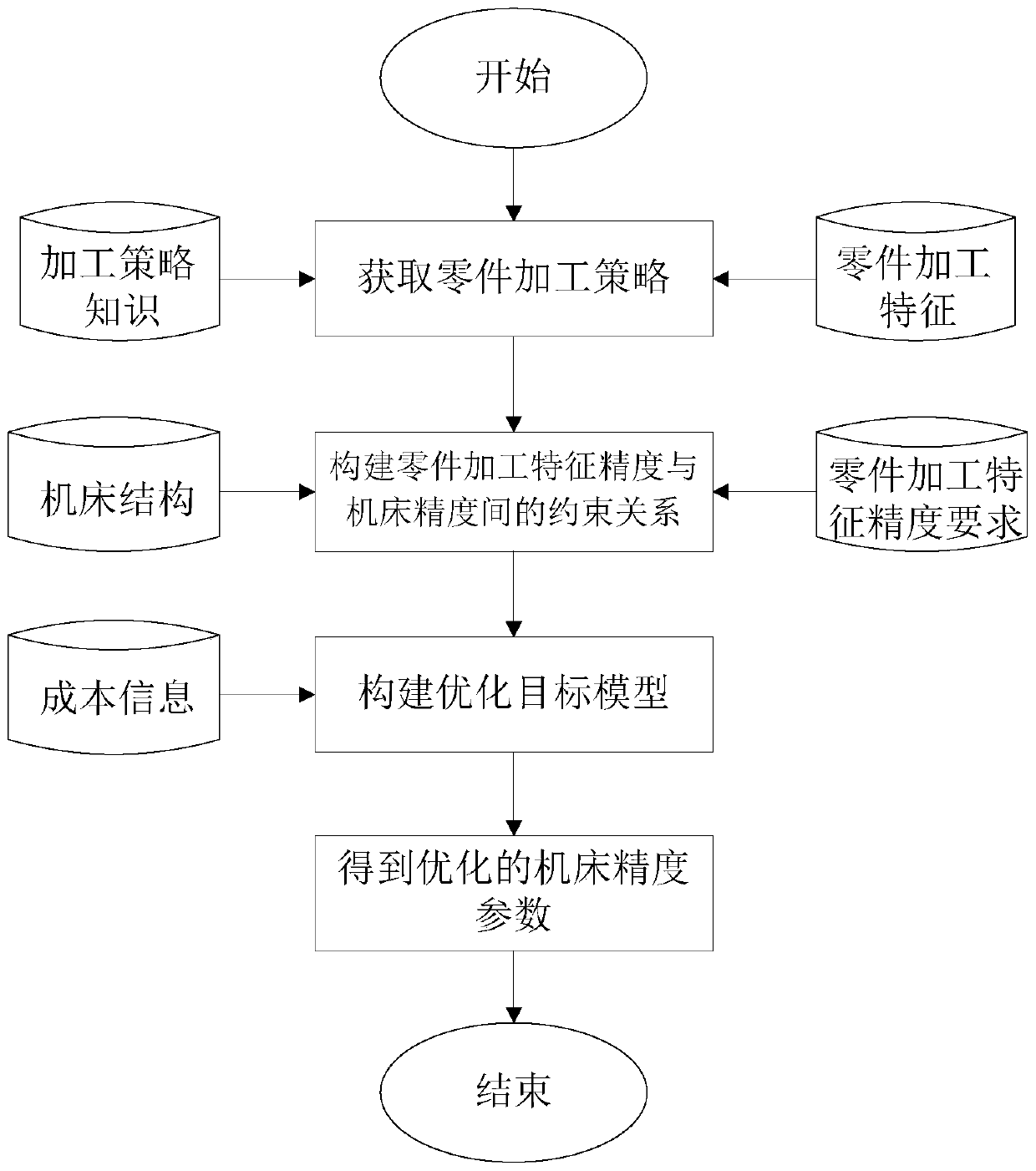

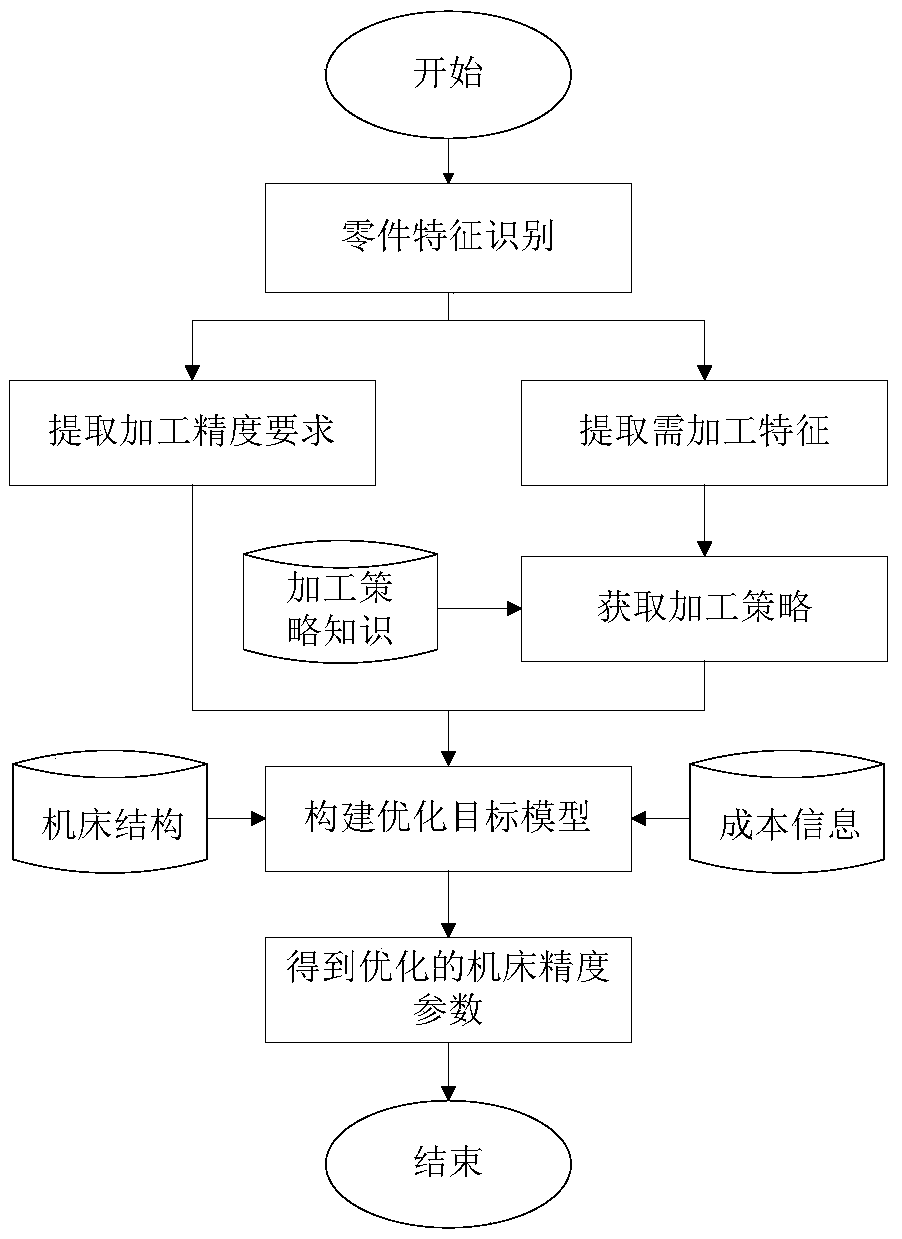

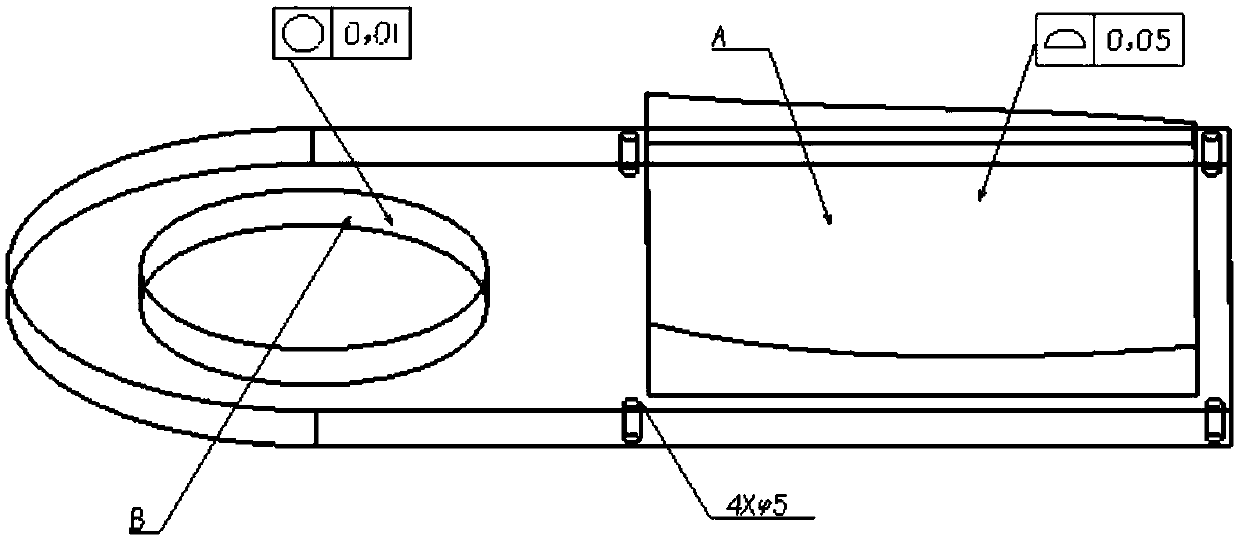

[0051] The present invention proposes a feature-based machine tool precision optimization design method, such as figure 1 As shown in the overall plan diagram, first, the feature recognition is performed through the part model, and the feature list of the features to be processed and the corresponding processing accuracy requirements are extracted from the obtained feature recognition results, and the processing strategy of the required processing features is obtained according to the processing strategy knowledge. Then, according to the machining strategy, machine tool structure and machining accuracy requirements, the constraint function between machine tool accuracy and machining accuracy requirements is constructed, and a feature-based optimization design model of machine tool accuracy is constructed by combining cost informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com