Touch control unit, preparation method thereof, and touch control substrate

A technology of touch control unit and touch electrode, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve the problems of low touch recognition accuracy and improve the amount of useful information and signal-to-noise The effect of improving the ratio and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

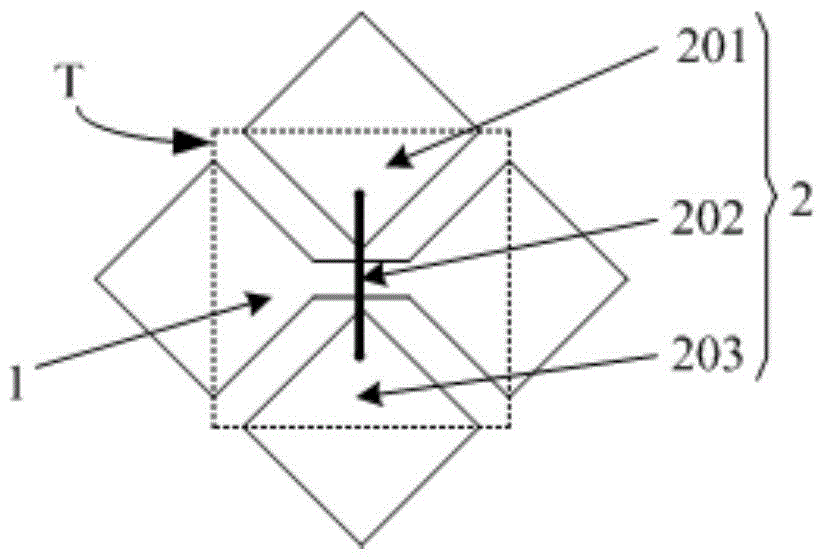

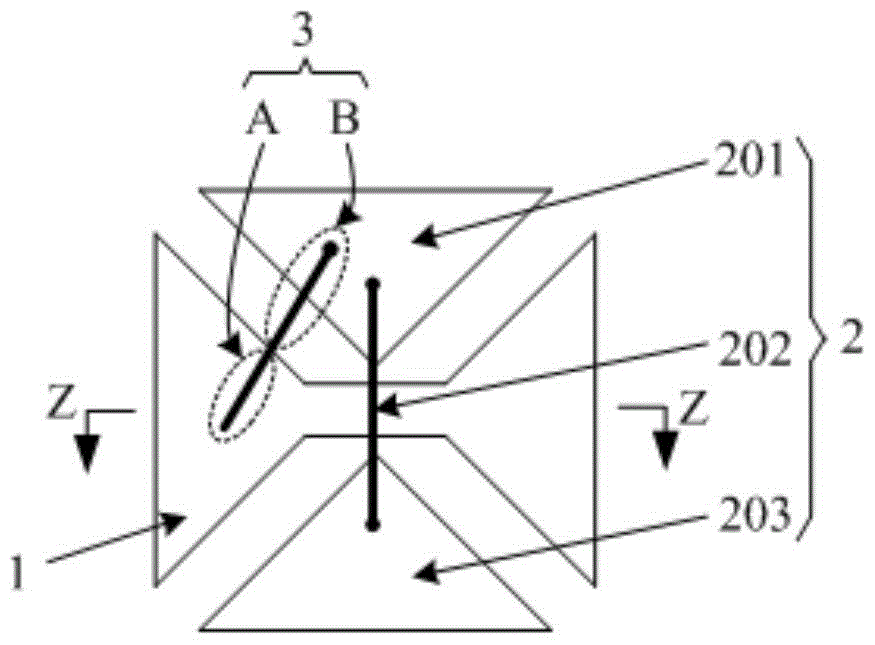

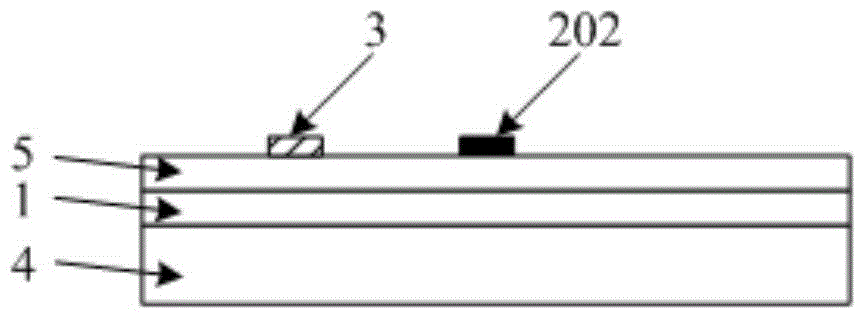

[0039] figure 2 It is a schematic structural diagram of a touch control unit provided in Embodiment 1 of the present invention, image 3 for figure 2 Schematic diagram of the interface in the Z-Z direction, such as figure 2 and image 3 As shown, the touch control unit includes: a first touch electrode 1, a second touch electrode 2 and a conductive branch 3, wherein the second touch electrode 2 includes: a first sub-electrode 201, a second sub-electrode 203 and a conductive bridge The line 202, the first sub-electrode 201 and the second sub-electrode 203 are respectively located on both sides of the first touch electrode 1, the conductive bridge line 202 crosses the first touch electrode 1 and its two ends are respectively connected to the first sub-electrode 201 and the second touch electrode. The two sub-electrodes 203 are connected, the conductive branch 3 is connected to the second touch electrode 2 and insulated from the first touch electrode 1, and the orthographic...

Embodiment 2

[0056] Figure 6 A flow chart of a method for manufacturing a touch unit provided in Embodiment 2 of the present invention, as shown in Figure 6 As shown, the preparation method is used to prepare the touch unit provided in the first embodiment above, and the preparation method includes:

[0057] Step S1, forming first touch electrodes on the base substrate.

[0058] Step S2, forming second touch electrodes on the base substrate.

[0059] Wherein, the second touch electrode includes: a first sub-electrode, a second sub-electrode and a conductive bridge line, the first sub-electrode and the second sub-electrode are respectively located on both sides of the first touch electrode, and the conductive bridge line crosses the first The two ends of the touch electrode are respectively connected with the first sub-electrode and the second sub-electrode.

[0060] Step S3, forming conductive branches.

[0061] Wherein, the conductive branch is connected to the second touch electrod...

Embodiment 3

[0075] Figure 8 A schematic structural diagram of a touch substrate provided in Embodiment 3 of the present invention, as shown in Figure 8 As shown, the touch control substrate includes a base substrate (not shown) and a touch control unit T located above the base substrate, wherein the touch control unit T adopts the touch control unit provided in the first embodiment above, and details can be found in The description in the first embodiment above will not be repeated here.

[0076]In this embodiment, when there are multiple touch units T, the first touch electrodes 1 in each touch unit T extend along the first direction X, and the second touch electrodes 2 extend along the second direction Y. , all touch units T form a touch array; in the touch array, the first touch electrodes 1 of each touch unit T arranged along the first direction X are connected, and the first touch electrodes 1 of each touch unit T arranged along the second direction Y The second touch electrode 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com