Disconnecting switch used for large current ice melting of high-voltage power transmission line

A high-voltage transmission line and isolation switch technology, applied in electrical switches, high-voltage air circuit breakers, circuits, etc., can solve the problem of inability to meet the requirements of large-section wire melting ice, low contact pressure of contacts and fingers, isolation switch ablation, etc. problem, to achieve the effect of good heat dissipation, convenient line access, and improved flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

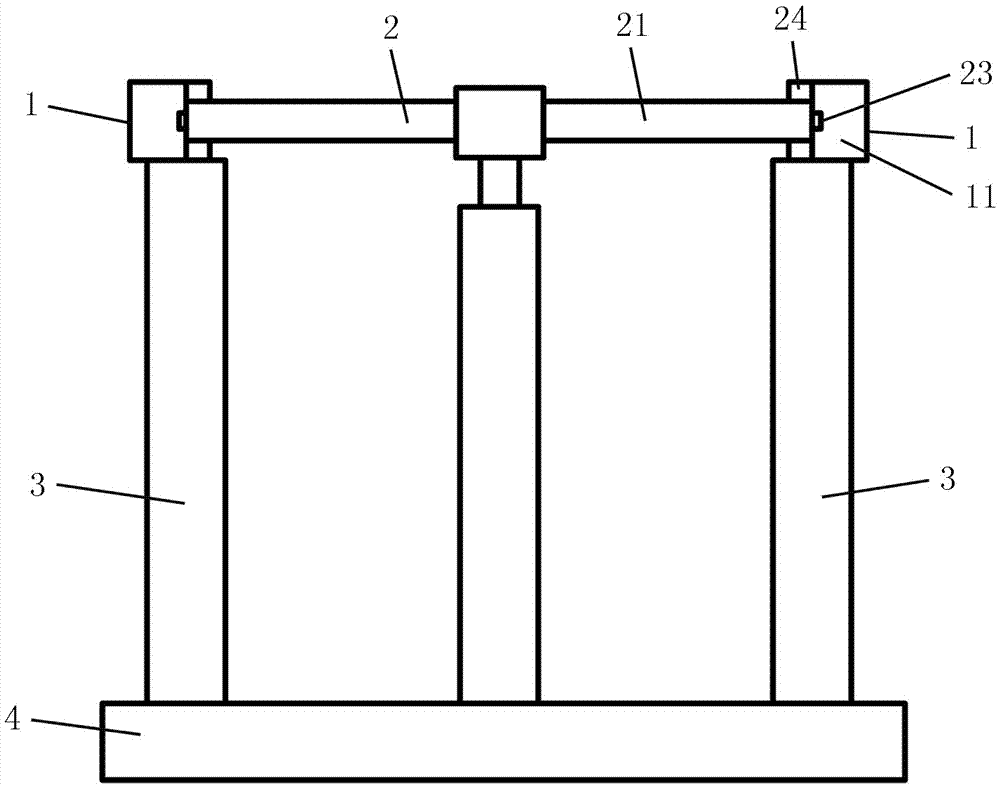

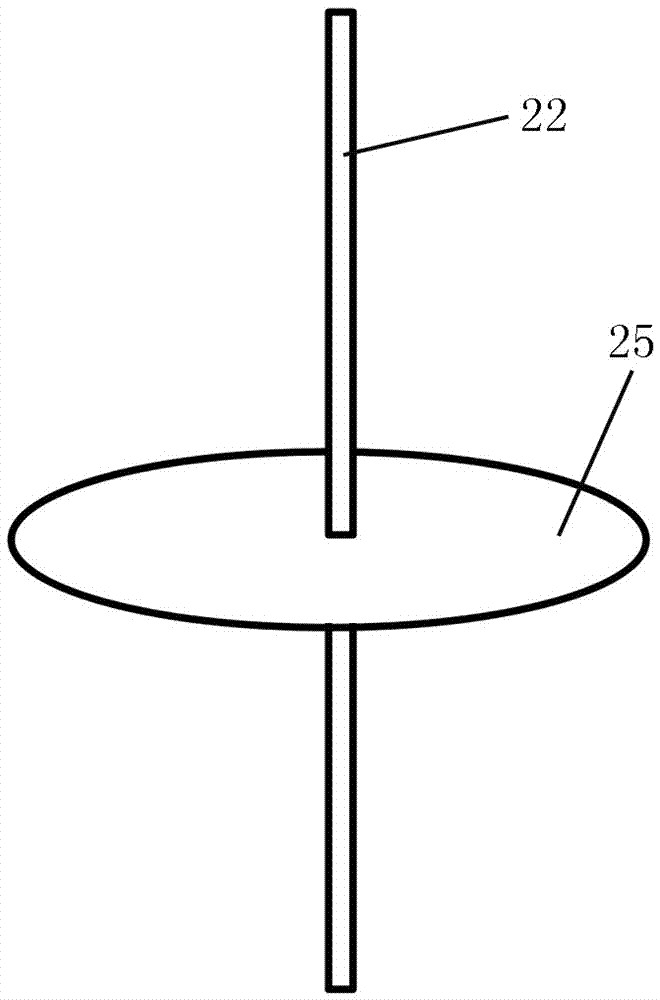

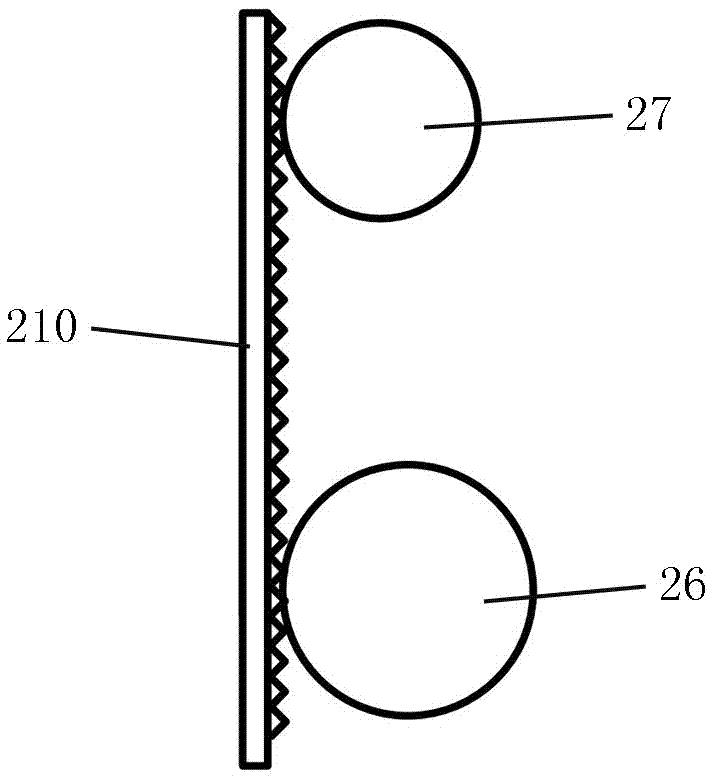

[0021] Such as figure 1 As shown, the isolating switch for high-current ice melting of high-voltage transmission lines of the present invention includes two static contacts 1 respectively connected to the output end of the ice melting device and the line to be melted, and two static contacts for connecting or disconnecting the two static contacts. The on-off control device 2 of the head 1, the two static contacts 1 and the on-off control device 2 are respectively installed on a base 4 through the insulator pillar 3, the on-off control device 2 includes a conduction shaft 21 and rotatably arranged on the insulator pillar 3 on the insulated rotating shaft 22, two static contacts 1 are provided on both sides of the insulated rotating shaft 22, each static contact 1 is provided with a U-shaped groove 11, the conducting shaft 21 is installed on the insulat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap