Low-mutual-inductance fault tolerance type six-phase double-salient-pole brushless DC motor

A brushed DC motor, doubly salient technology, applied in the shape/pattern/structure of magnetic circuit, static parts of magnetic circuit, shape/pattern/structure of winding conductor, etc., can solve the problems of strong mutual inductance between phases and poor fault tolerance performance. , to achieve the effect of electrical isolation, good fault tolerance, and small mutual inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

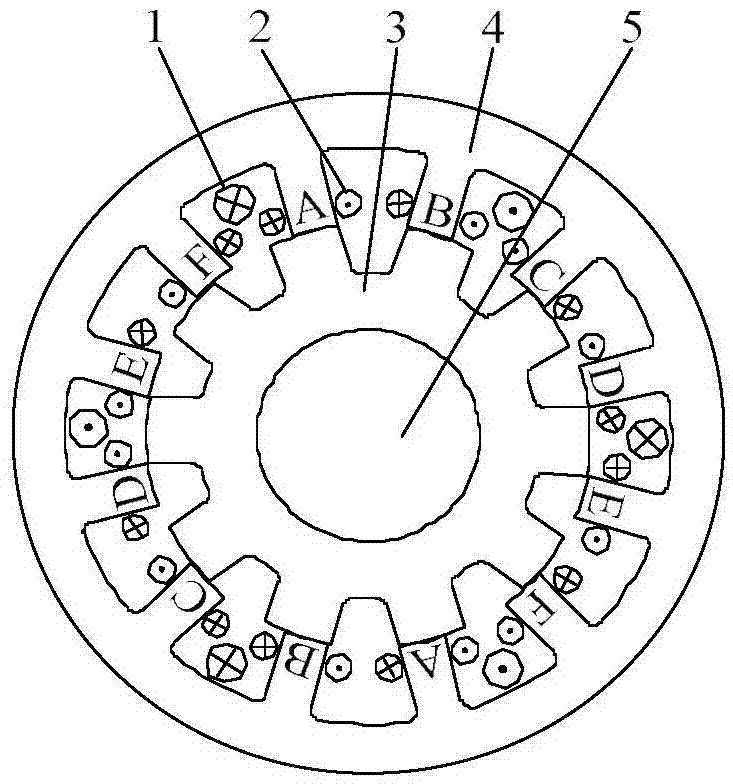

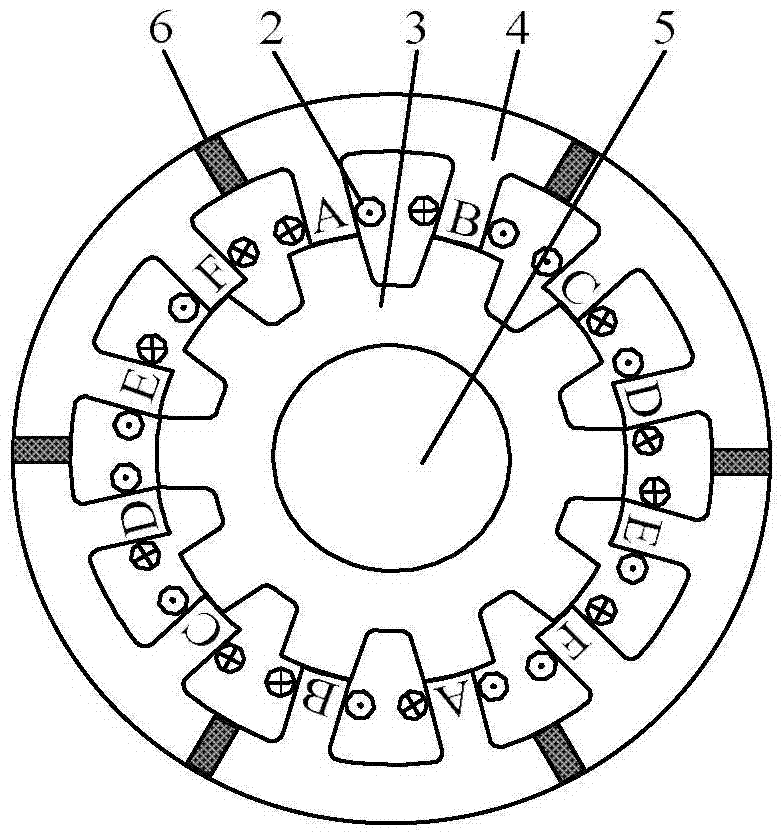

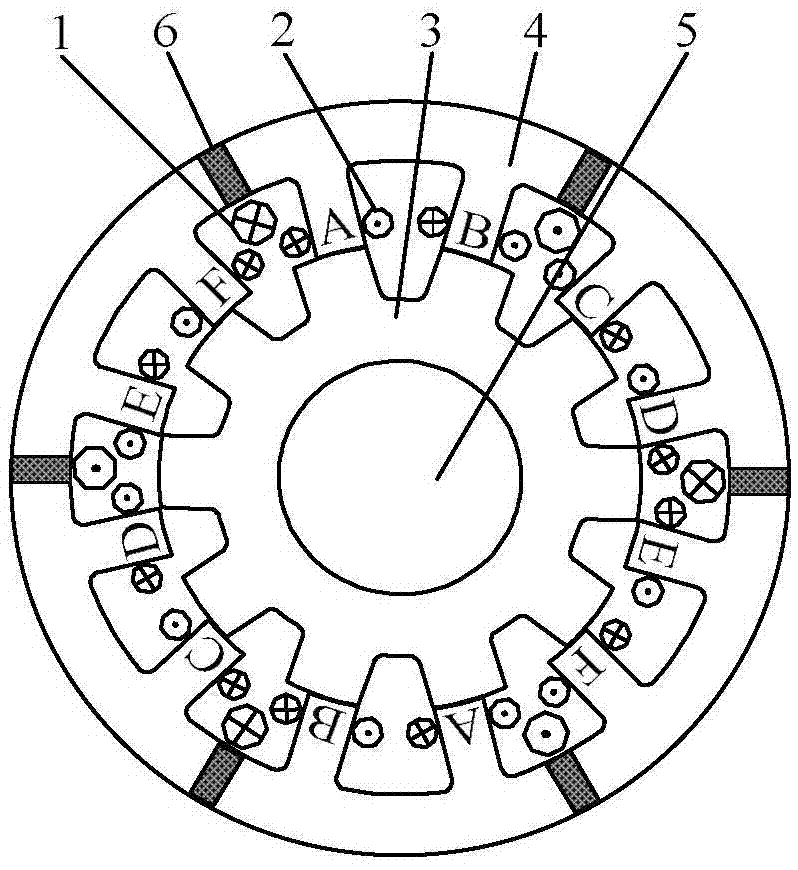

[0032] The invention discloses a low mutual inductance fault-tolerant six-phase double-salient pole brushless DC motor, which comprises a stator assembly and a rotor core arranged on the same rotating shaft; the stator assembly includes a stator core, an excitation element and a six-phase stator winding; the stator The iron core is provided with stator poles, and the excitation element and the six-phase stator winding are embedded in the corresponding stator poles; the rotor iron core is provided with rotor poles;

[0033] The number of stator poles on the stator core is 12N, and the number of rotor poles on the rotor core is 10N or 14N, where N is a natural number;

[0034] The number of the excitation elements is 6N, and each excitation element is arranged across two stator poles, and adjacent excitation elements are connected with opposite polar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com