Brushless direct current motor

A DC motor and stator technology, applied in electrical components, electromechanical devices, torque ripple control, etc., can solve the problems of insufficient torque, power consumption, power supply limitation of brushless DC motors, etc., to reduce cogging torque and reduce the use of Power limitation, power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

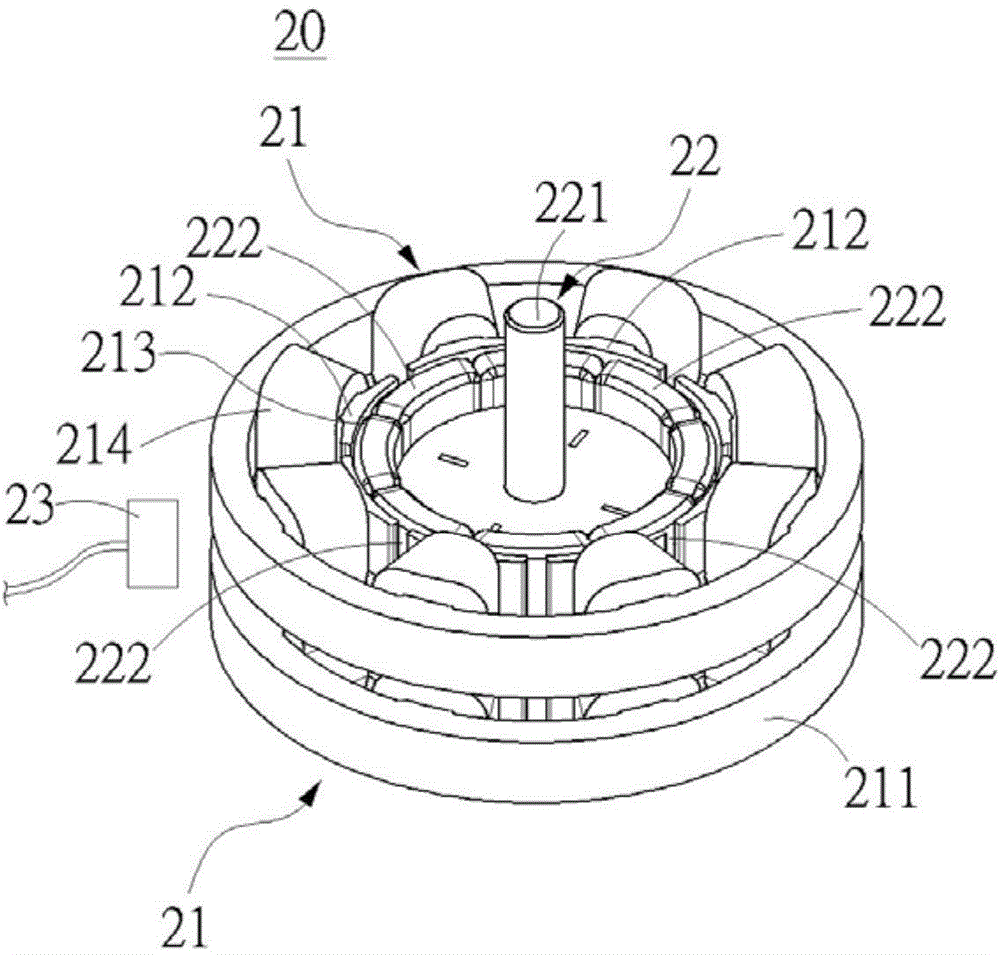

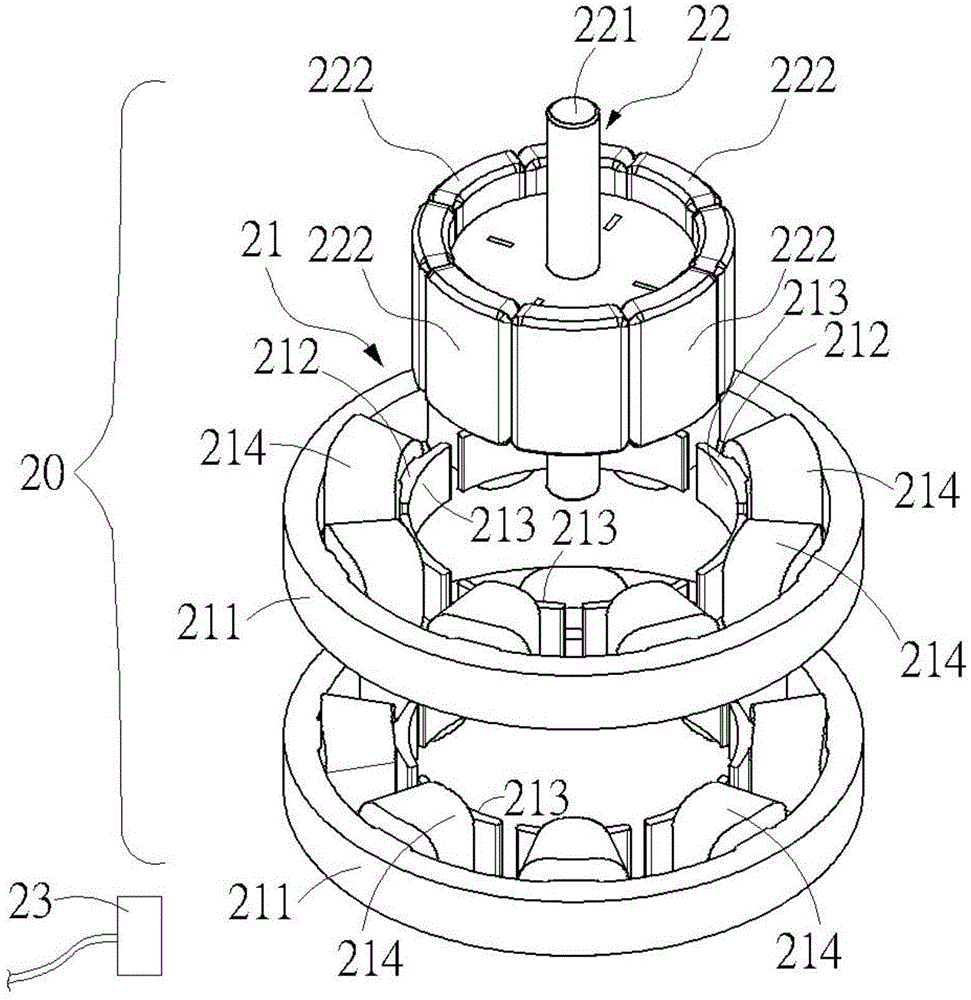

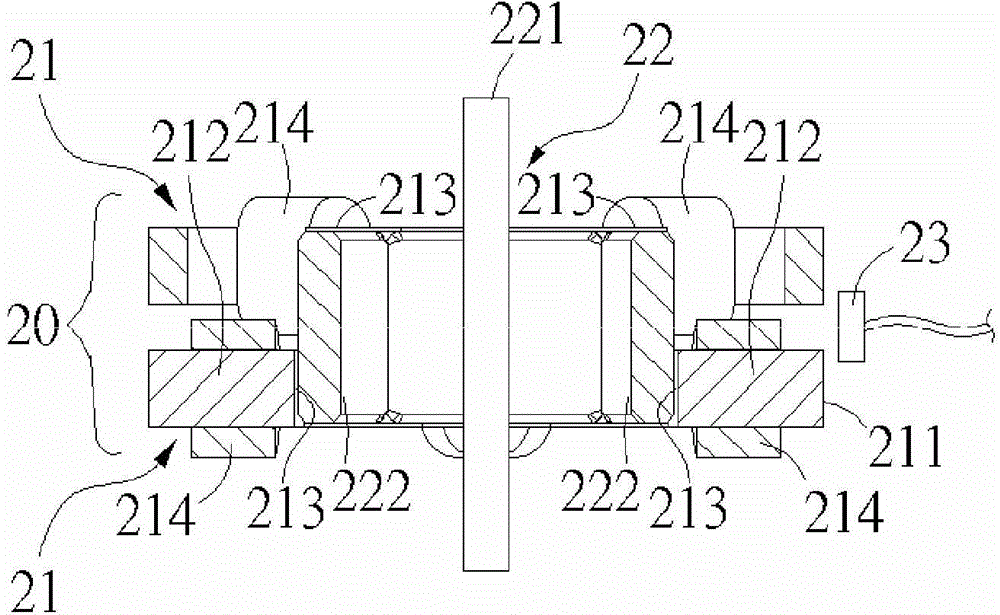

[0042] The present invention mainly provides a brushless DC motor capable of generating high torque output at low rotational speed and low torque output at high rotational speed, such as figure 1 The perspective view of the appearance of the brushless DC motor of the present invention, figure 2 Structure exploded view of the brushless DC motor of the present invention, image 3 As shown in the sectional view of the structure of the brushless DC motor of the present invention, the brushless DC motor 20 of the present invention basically includes: two stators 21, and a rotor 22; wherein: the two stators 21 are arranged along the same axis Set, each stator 21 has a body 211 in the shape of a ring, on which body 211 is provided with stator teeth 212 extending towards the center of the body 211, and a boot 213 is formed at the tail end of each stator tooth 212, on each stator tooth 213 is wound with a coil 214 with a predetermined gate number, wherein the gap between the boots 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com