A driving device and control method for a permanent magnet linear motor

A permanent magnet linear motor and control method technology, applied in the control of motor speed or torque, AC motor control, electromechanical devices, etc., can solve problems such as restricting application, efficiency, and reliability, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

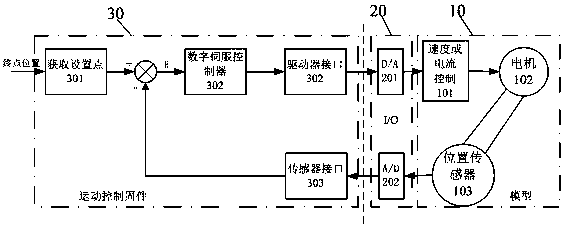

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

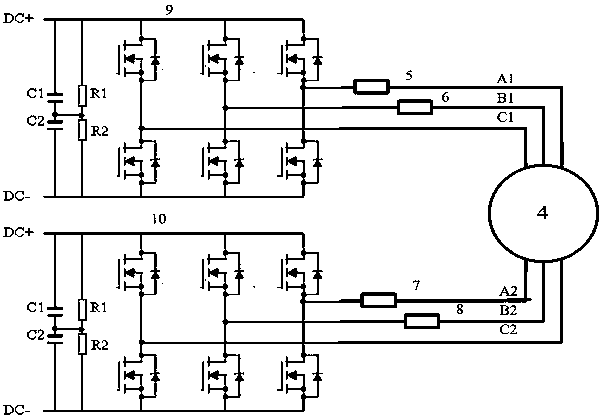

[0031] The driving device and control method of a permanent magnet linear motor described in the present invention is aimed at the defects of the prior art, and analyzes specific measures to improve efficiency and reliability. Taking a double-three-phase permanent magnet direct motor as the research object, The design of drive circuit, the automatic collection of fault points, the principle of fault switching, and the measures to improve reliability are analyzed, and a feasible reliability control scheme is described in detail.

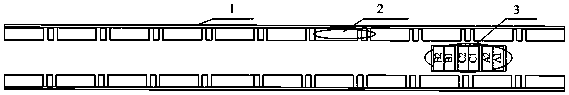

[0032] The motor is characterized in that the mover is a double-three-phase winding coreless structure, the stator adopts a Halbach permanent magnet array, the back iron is designed to be very thin, and is evenly distributed and symmetrically fixed on both sides of the mover, which solves the problem of the traditional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com