PCB board positioning method based on SCARA robot

A technology of PCB board and positioning method, which is applied to PCB positioning in the process of processing, assembling printed circuits with electrical components, etc., can solve the problems of mechanical positioning error, inability to meet high-precision assembly, etc., and achieve the effect of high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be clearly and completely described below.

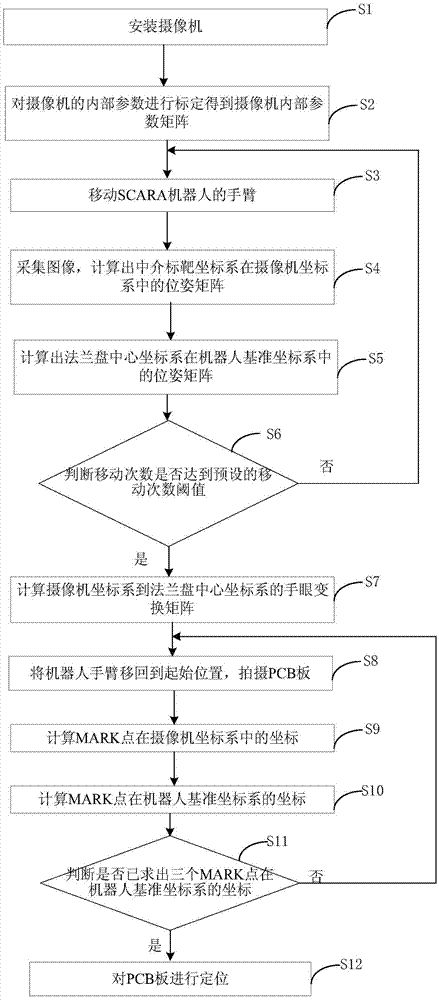

[0025] figure 1 It is a flow chart of the SCARA robot-based PCB board positioning method provided by Embodiment 1 of the present invention. Such as figure 1 as shown,

[0026] Step S1: Install the camera.

[0027] In step S1, the camera is fixedly installed on the Y-axis arm of the SCARA robot, so that the SCARA robot works in the pulse motion mode and ensures that the relative position of the camera coordinate system and the flange center coordinate system remains unchanged when the SCARA robot arm moves. The intermediate target is fixedly set directly below the CCD.

[0028] Step S2: Calibrate the internal parameters of the camera to obtain the internal parameter matrix of the camera.

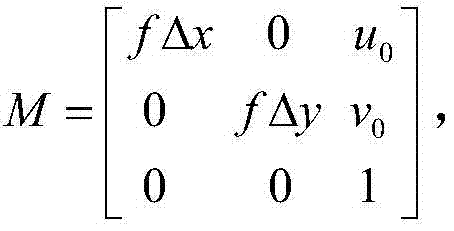

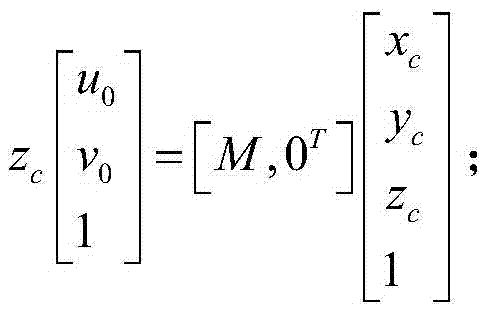

[0029] In step S2, use the camera calibration technology to calibrate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com