Barrel washer

A barrel washing machine and empty barrel technology, applied in the field of barrel washing machines, can solve the problems of high labor cost, low cleaning efficiency, large waste of water and detergent, etc., and achieve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

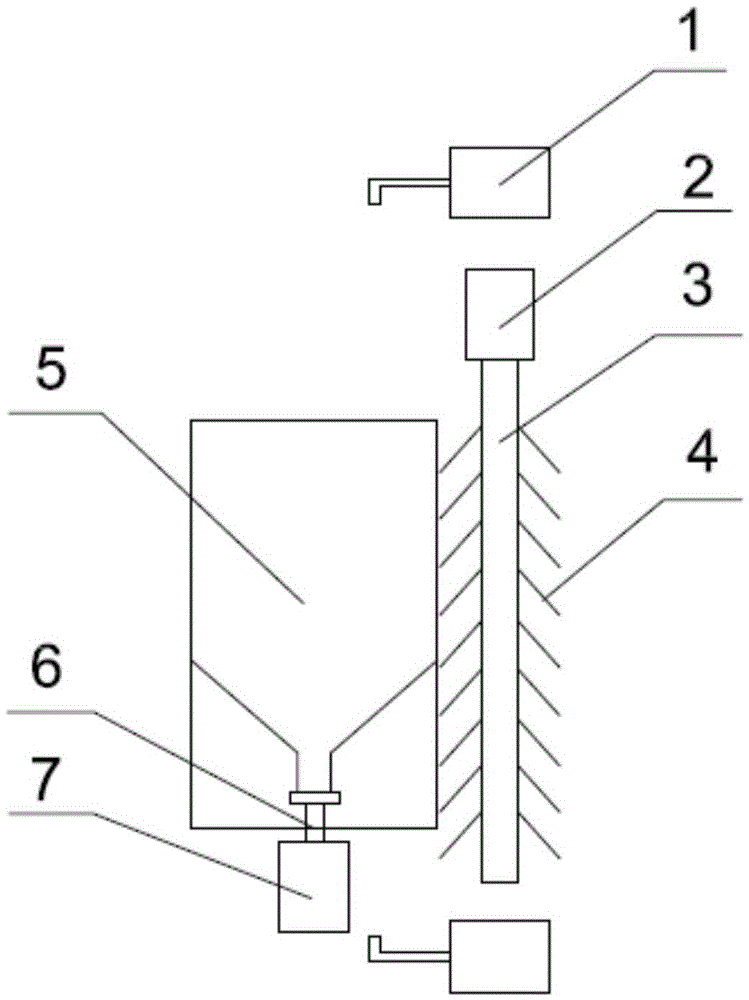

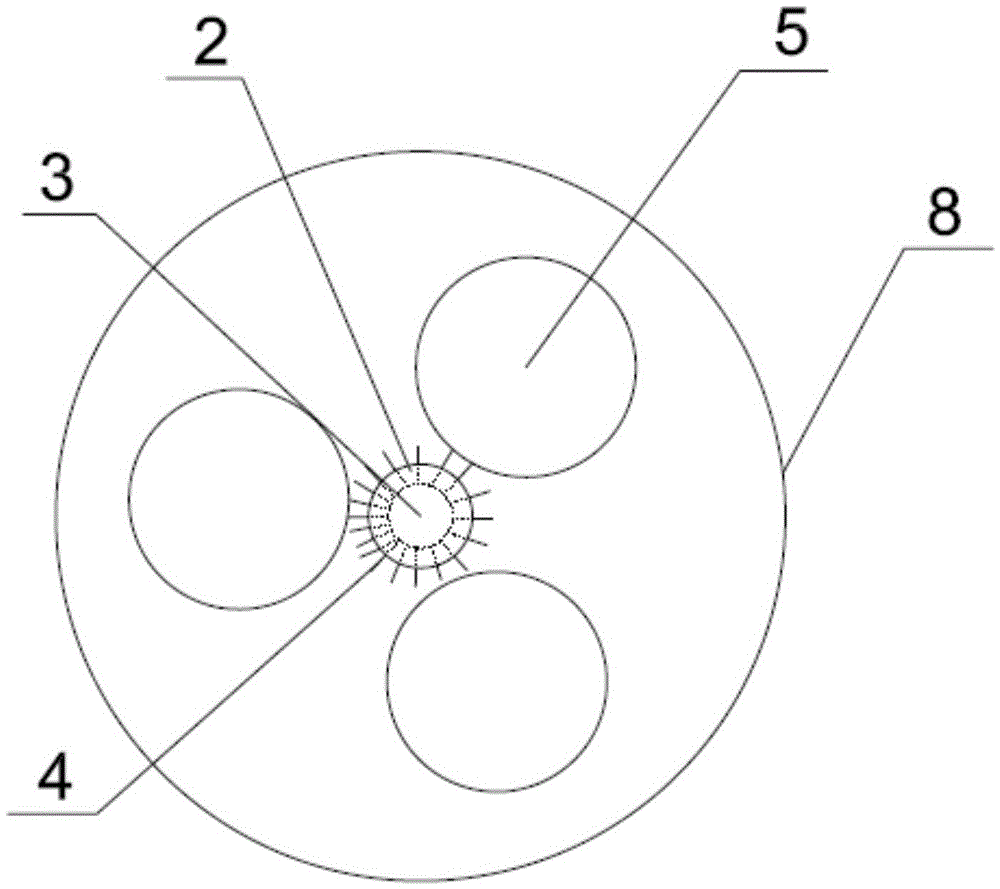

[0016] A bucket washing machine, comprising a water tank 1, a cleaning motor 2, a cleaning rotating shaft 3, a cleaning brush 4, an empty bucket rotating motor 7, and an empty bucket rotating shaft 6; the water tank 1 is located above and below the cleaned empty bucket 5 position; the cleaning motor 2 is connected to the cleaning rotating shaft 3; the cleaning brush 4 is arranged on the outer surface of the cleaning rotating shaft 3; the cleaning brush 4 contacts the outer wall of the empty barrel 5; the empty barrel rotating motor 7 is connected to the empty barrel A rotating shaft 6 ; the empty barrel rotating shaft 6 is connected to the empty barrel 5 . A water retaining ring 8 is provided outside the barrel washing machine and the empty barrel 5 .

[0017] The empty barrel rotating motor 7 and the empty barrel rotating shaft 6 are arranged in three groups, and are arranged around the cleaning rotating shaft 3 , and each empty barrel rotating shaft 6 is connected with an em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com