Inclined workpiece table grinding machine

A technology of inclined work and workpiece table, which is applied in the direction of grinding frame, grinder, manufacturing tools, etc., can solve the problems of low flatness and polishing standard, residues that cannot be cleaned, residues left, etc., to improve processing accuracy and Polishing standard, convenient residue and cleaning sewage, convenient centralized collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An exemplary embodiment of the present invention will be described in detail below with reference to the accompanying drawings. The purpose of providing these exemplary embodiments is to enable one of ordinary skill in the art to clearly understand the invention, and the present invention can be implemented in accordance with the description herein. The accompanying drawings and specific embodiments are not intended to limit the invention, and the scope of the invention is defined by the appended claims.

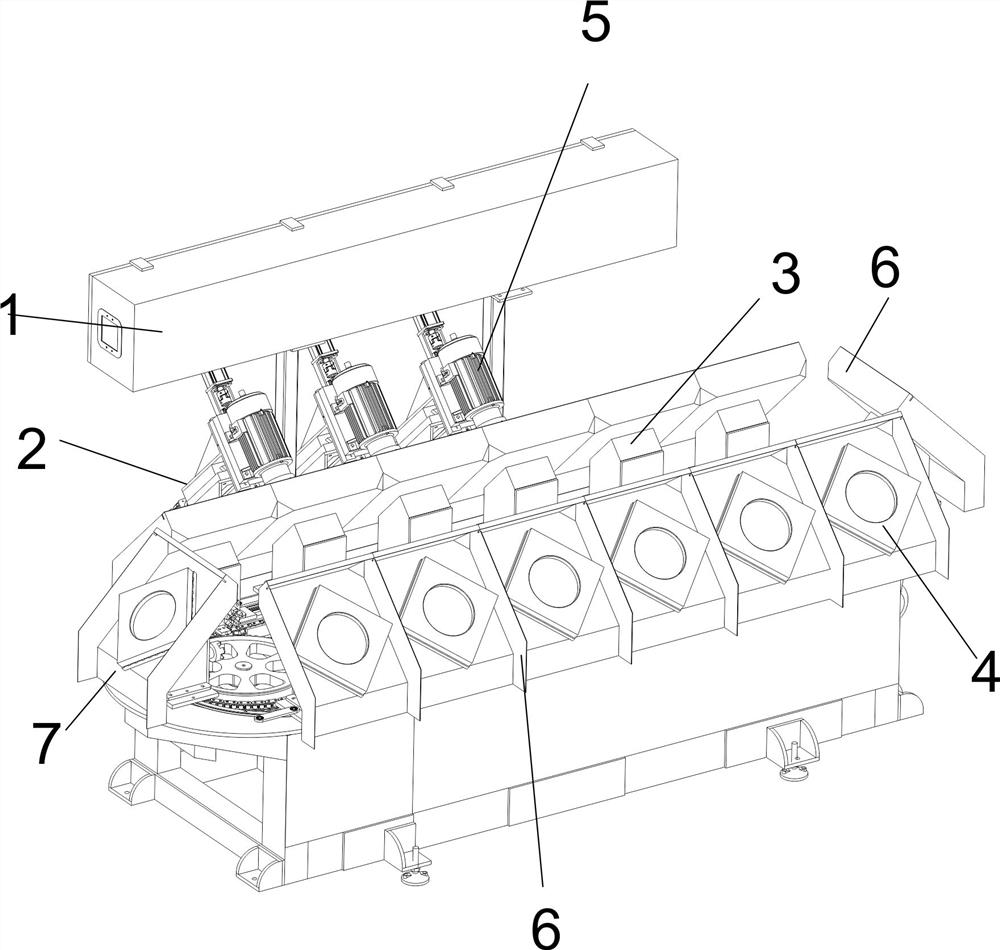

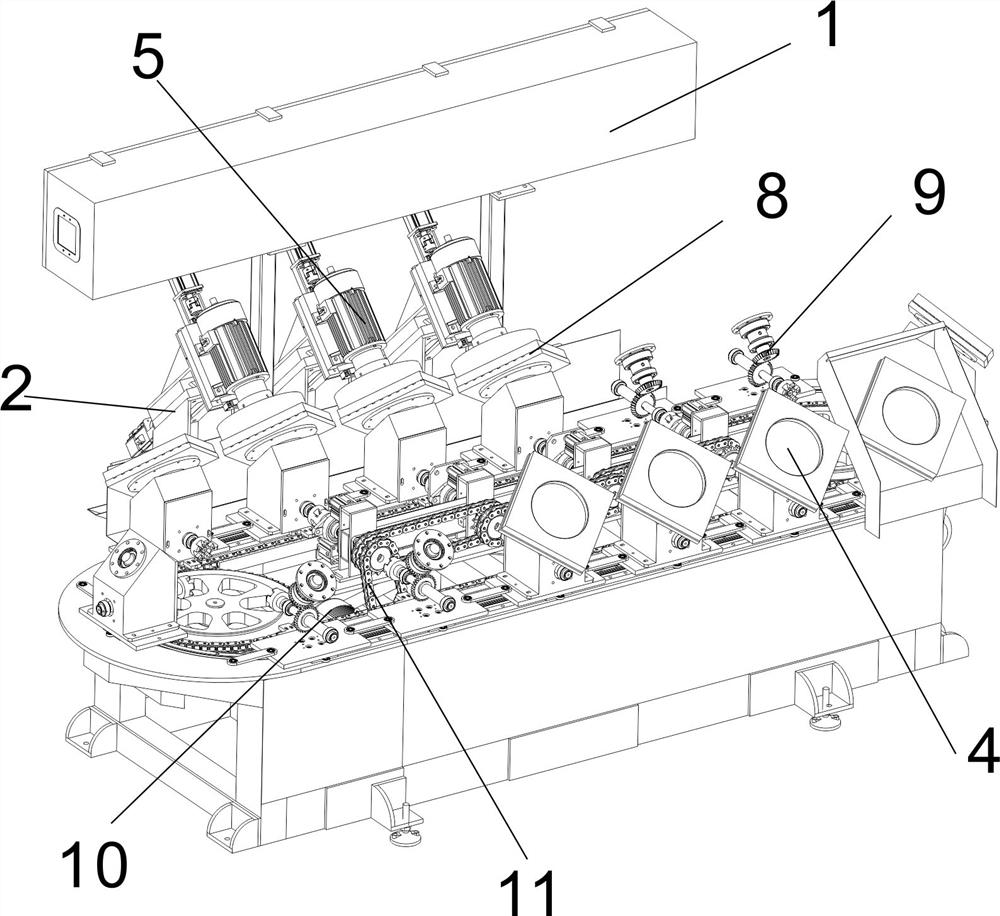

[0016] Such as figure 1 As shown, an inclined workpiece table mill is provided, and its workpiece table is arranged to be tilted or perpendicular to the horizontal plane, so that it is conducive to processing residue to flow out, improve machining accuracy;

[0017] The priority workpiece table is arranged in a level 45 degree angle arrangement, which is convenient for the placement of the processing product, and is convenient to clean the flow of sewage.

[0018] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com