Working table device for panel machining and with limiting sensor and solar panel and using method of working table device

A limit sensor, solar panel technology, applied in the field of sheet metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

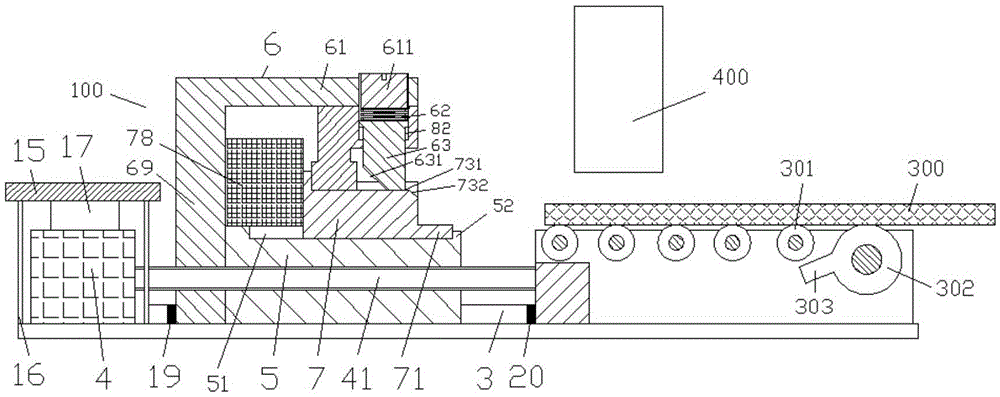

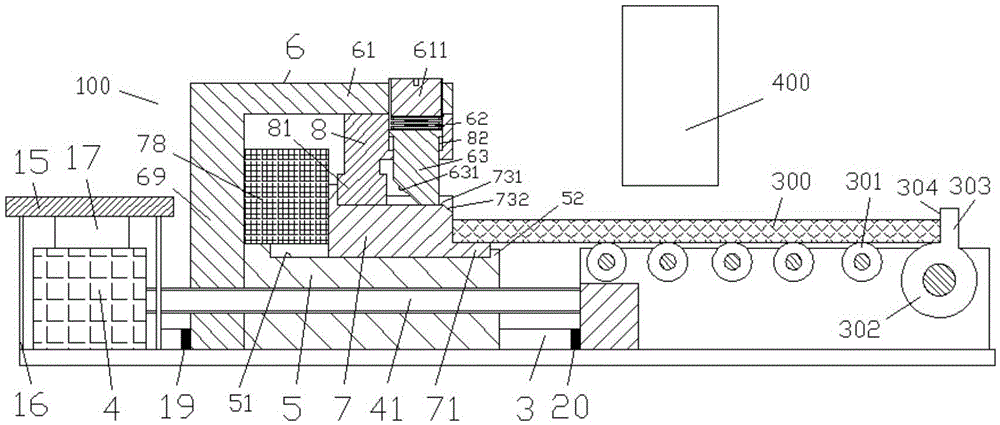

[0011] Combine below Figure 1-2 The present invention will be described in detail.

[0012] According to an embodiment, a workbench device with a limit sensor and a solar panel for plate processing includes a transmission support device fixedly connected to the frame, a locking drive motor 4 fixedly connected to the frame, and the The driving screw 41 power-coupled with the locking drive motor 4, and the locking assembly 100 driven by the screw thread on the driving screw 41, wherein the locking assembly 100 is used to lock the plate under the drive of the locking driving motor 4 300 close to the side of the locking assembly 100 for positioning and locking; a solar panel 15 is provided directly above the locking drive motor 4, and a battery 17 is provided between the locking drive motor 4 and the solar panel 15, so The locking drive motor 4, the storage battery 17 and the solar panel 15 are electrically connected in sequence, so that the solar panel 15 is used to convert sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com