Thread support mechanism

A technology of bracket mechanism and twisted tooth, which is applied in the field of twisted tooth bracket mechanism, can solve problems such as difficult adjustment, left and right imbalance, cumbersome operation, etc., and achieve the effect of reducing wear and preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

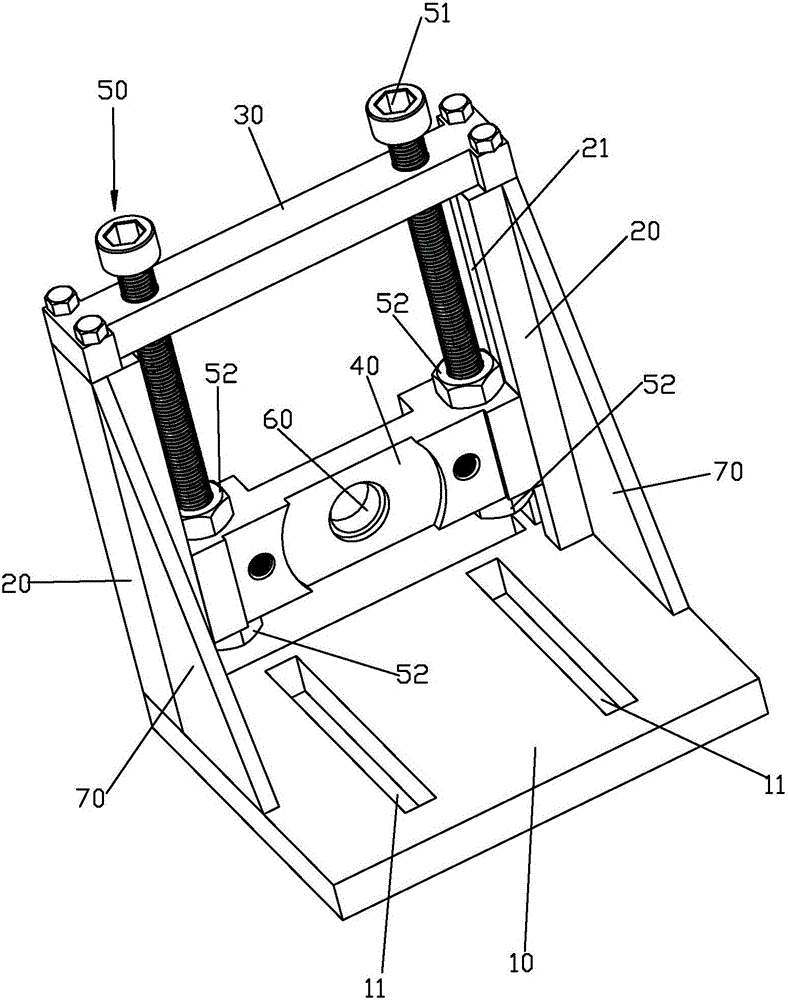

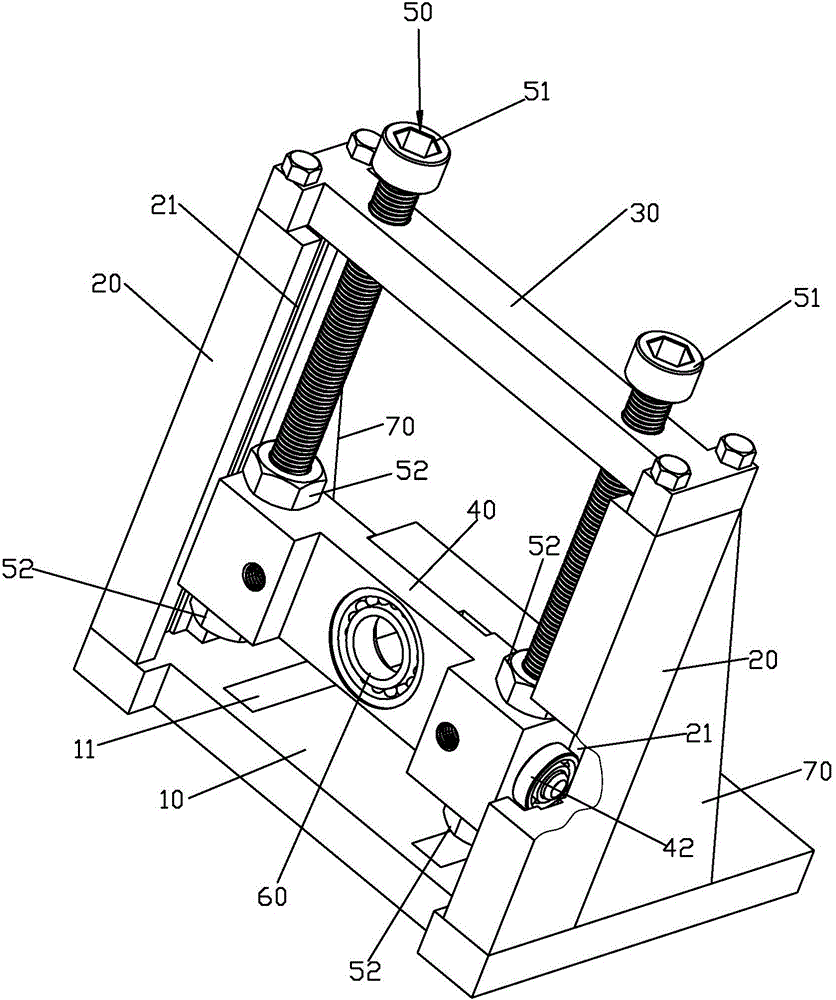

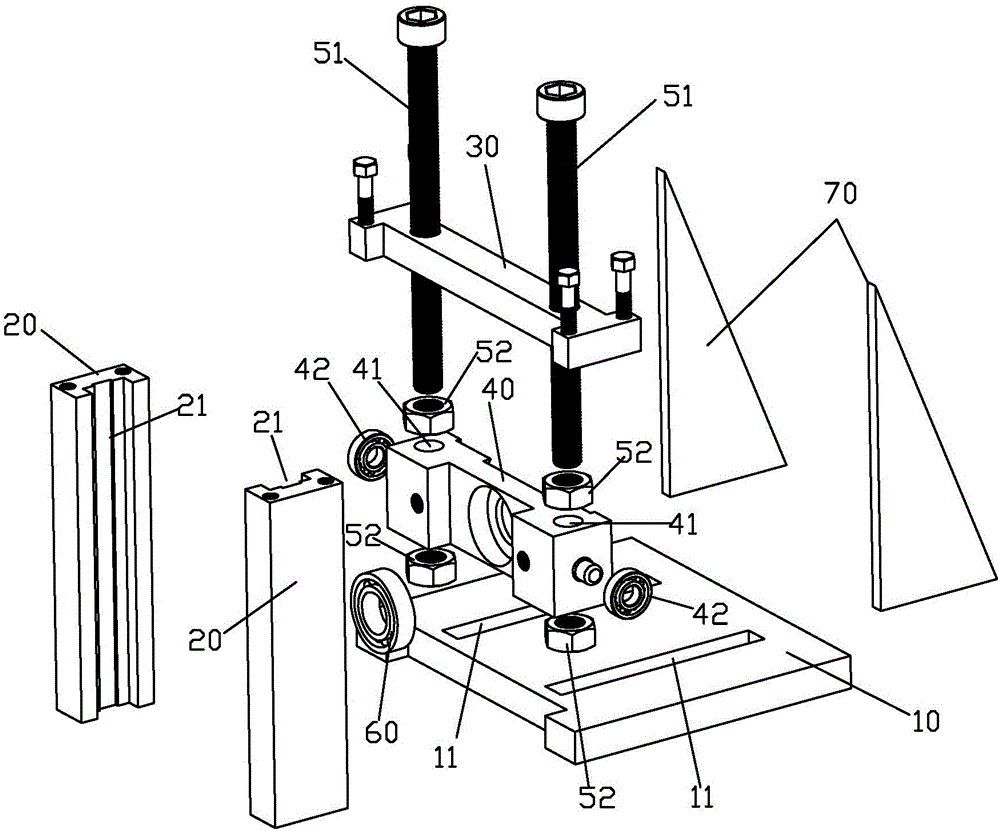

[0025] Please check Figure 1 to Figure 4 , The twisted tooth bracket mechanism includes a fixed seat 10 mounted on the template of the injection molding machine, two pillars 20, a cross bar 30, a load-bearing beam 40 and an adjustment mechanism 50. The load-bearing beam 40 is provided with a through hole penetrating front and rear, and a first bearing 60 is fixedly installed in the through hole.

[0026] The fixed seat 10 can be horizontally moved and adjusted to be mounted on the template of the injection molding machine. Preferably, the fixed seat 10 is provided with a horizontal chute 11 arranged in the front-rear direction and penetrates up and down. It is adjusted and attached to the mold plate of the injection molding machine by moving back and forth horizontally.

[0027] The two pillars 20 are vertically fixed on the fixing seat 10 , and the two pillars 20 are arranged at intervals from left to right; the cross bar 30 is fixed on the tops of the two pillars 20 by scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com