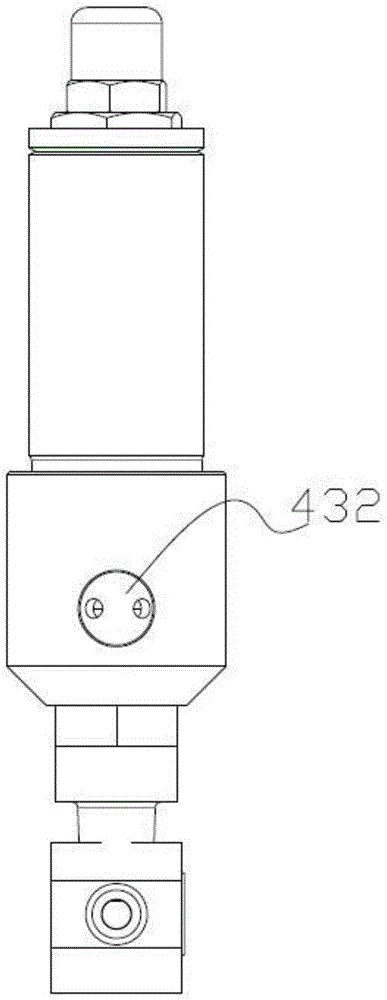

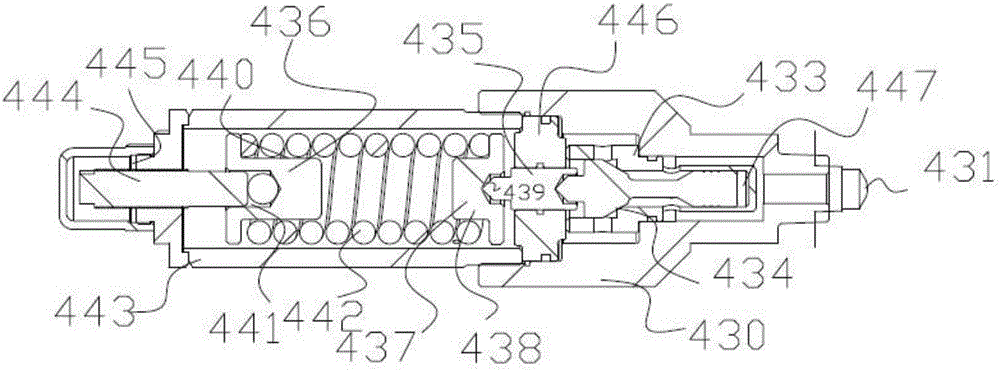

Safety valve for reciprocation pump

A safety valve, reciprocating pump technology, applied in safety valves, valve details, balance valves, etc., can solve the problems of easily damaged sealing pairs, large impact force on the sealing surface of the valve disc, affecting the sealing performance of the valve, etc., to achieve wear resistance performance. and stable improvement of mechanical properties, enhanced corrosion resistance and wear performance, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, the mass percentage composition of the alloy applied to the valve body includes Mg: 2.9%, Cr: 1%, Cu: 0.8%, Si: 0.47%, Ti: 1%, Re: 0.5%, Ni: 0.1%, Os particles: 0.24%, additives 0.1-0.3%, the balance is aluminum.

Embodiment 2

[0044]In this embodiment, the mass percentage composition of the alloy applied to the valve body includes Mg: 2.8%, Cr: 1.1%, Cu: 0.6%, Si: 0.48%, Ti: 0.08%, Re: 0.6%, Ni: 0.15%, Os particles: 0.16%, additives 0.1-0.3%, the balance is aluminum.

Embodiment 3

[0046] In this embodiment, the mass percentage composition of the alloy applied to the valve body includes Mg: 2.7%, Cr: 1.2%, Cu: 0.5%, Si: 0.31%, Ti: 0.06%, Re: 0.7%, Ni: 0.22%, Os particles: 0.29%, additives 0.1-0.3%, the balance is aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com